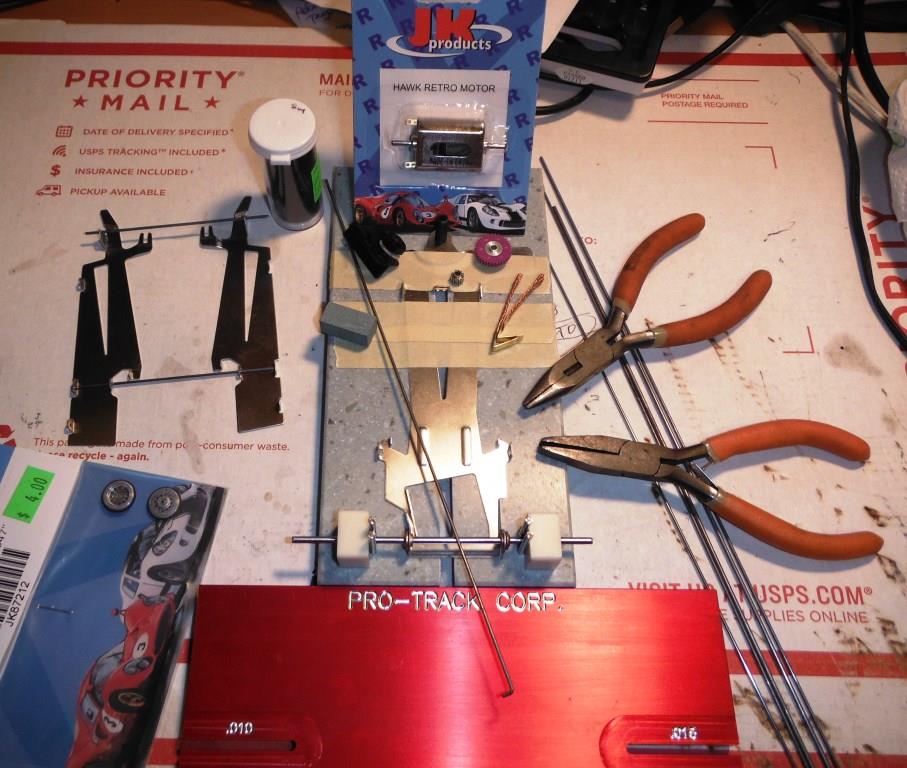

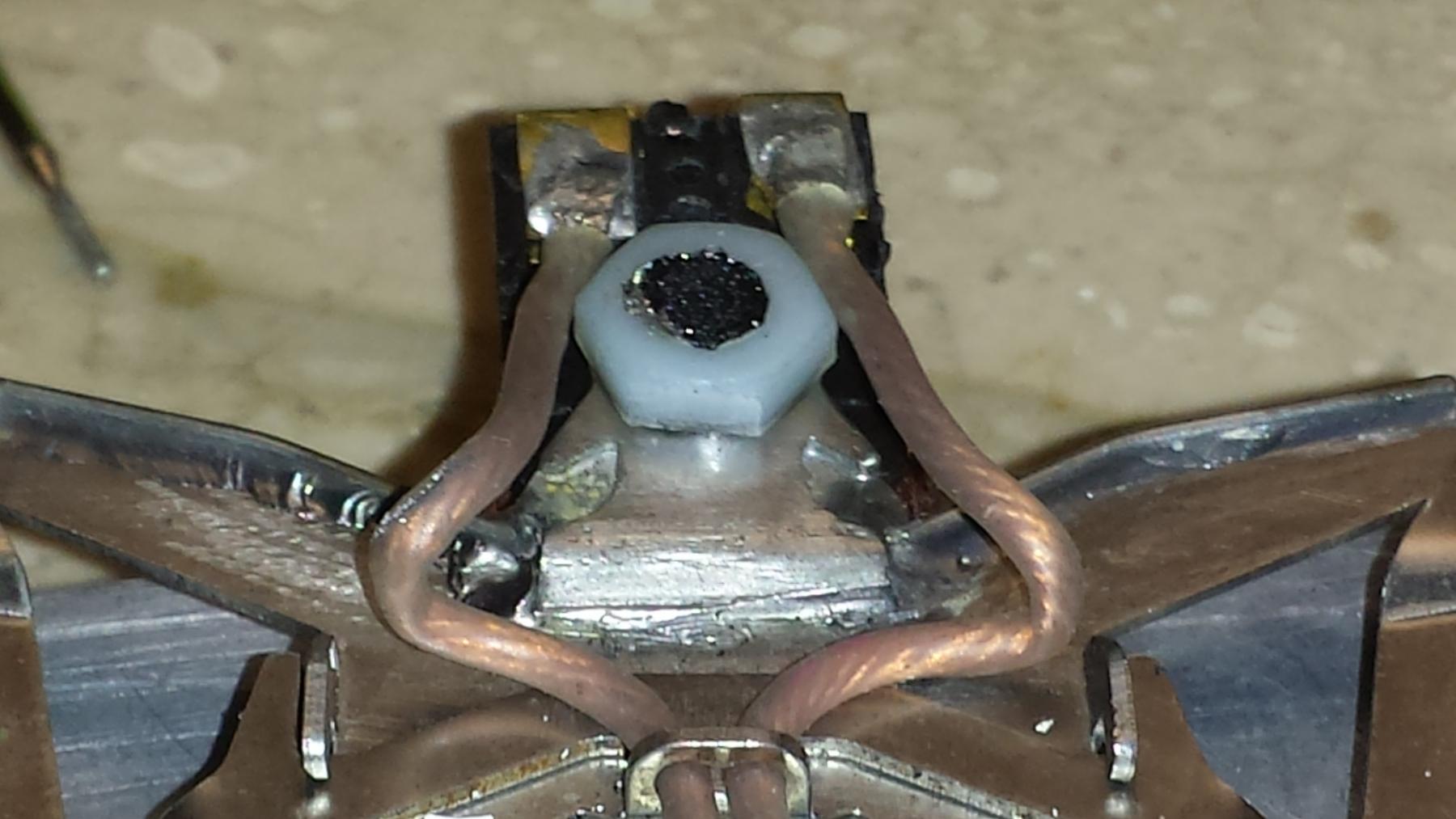

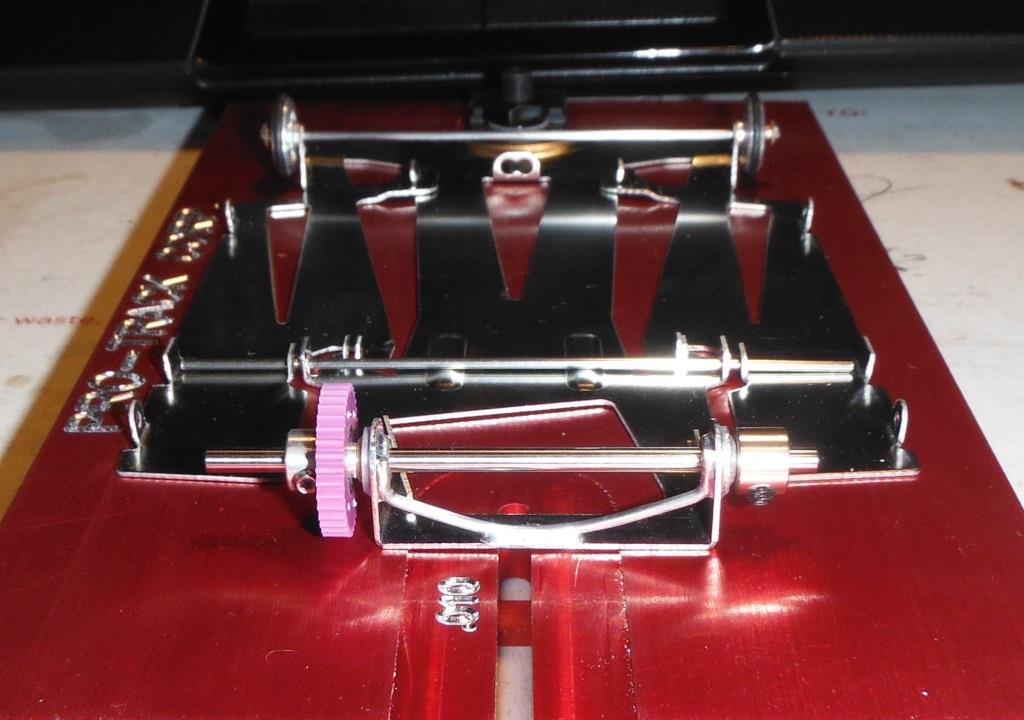

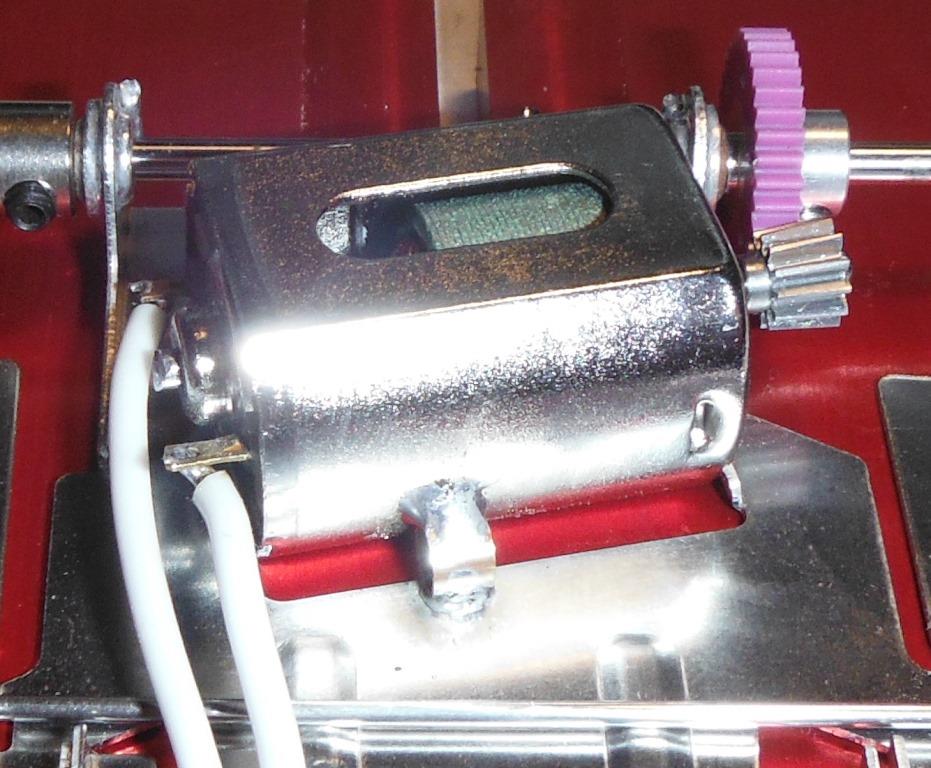

Santa got me some new toys - a Lucky Bob Chassis Jig and a set of 3/32 jig wheels. Now I can setup a JK C11 chassis the correct way in preparation for some MySeries racing in Florida. I spent the time and made sure all 3 pieces are completely flat, and uprights are square. Taped the chassis dead on center. The oilites move freely right now at the desired height but I want to solder braces around the motor compartment and to the uprights at same time before removing from jig...Can someone help me with ideas and/or images?