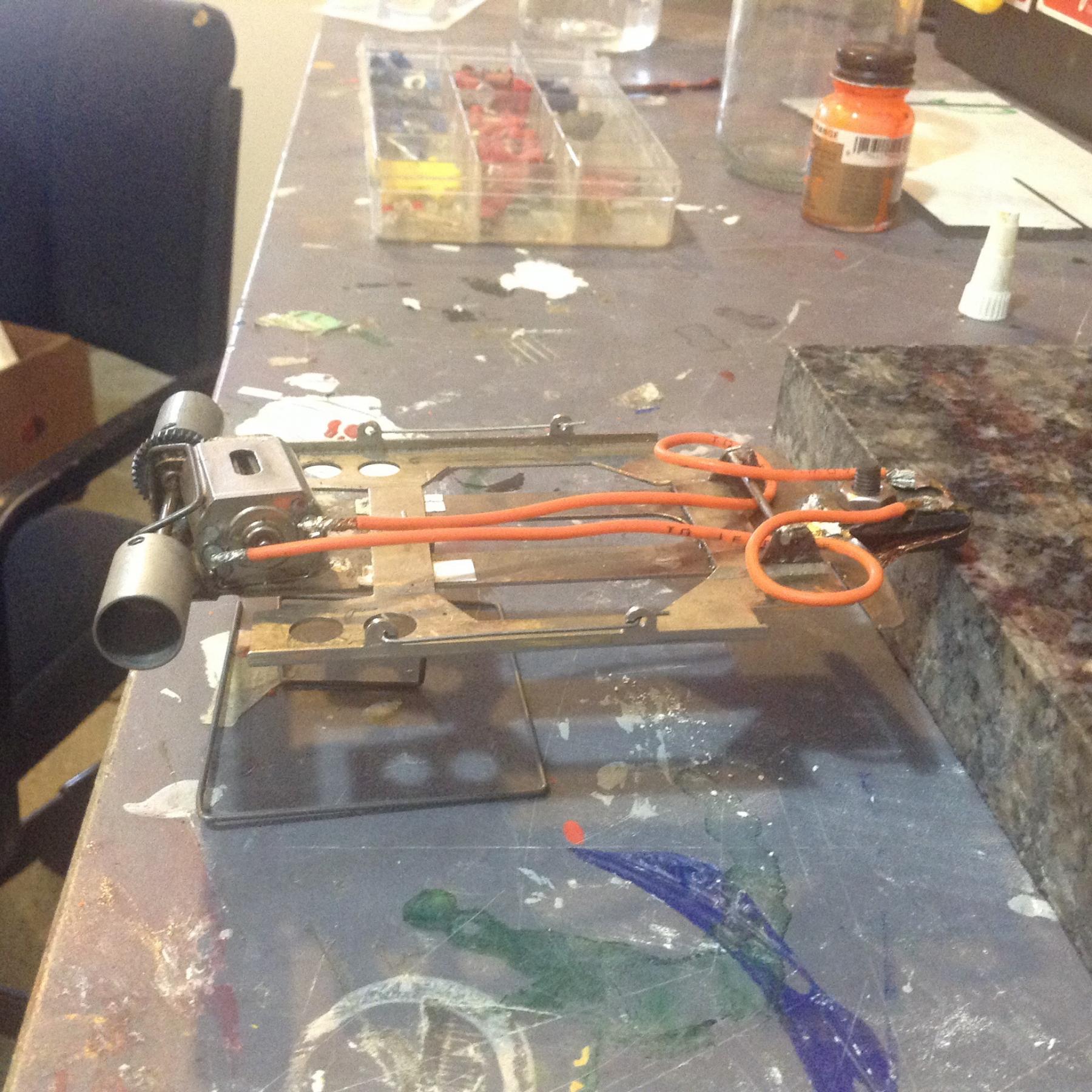

I made the hook slightly higher than the block to allow for the height of the guide flag. This allows the chassis to stay flat. Just make sure the guide is pointing straight ahead, rear wheels set to the correct width, lead wires in place, etc.

I also set it up without tyres as they can have a big difference in weight. I simply position the motor around until the chassis is dead flat and has a good tooth mesh. I then put a light champ on the motor to hold it in place and then hit it with some solder.

As you can see in the below photos it didn't get this one quite right, but it is pretty close to a 50/50 balance.

.jpg)