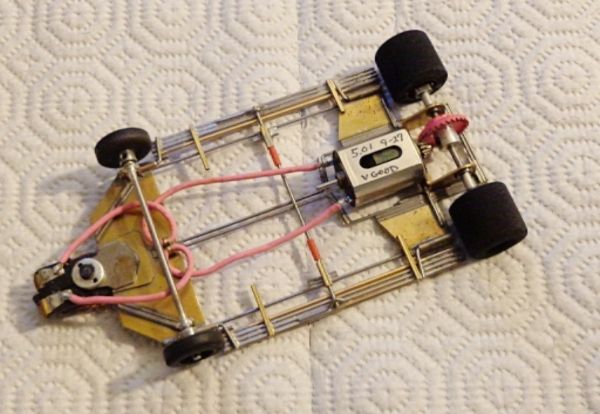

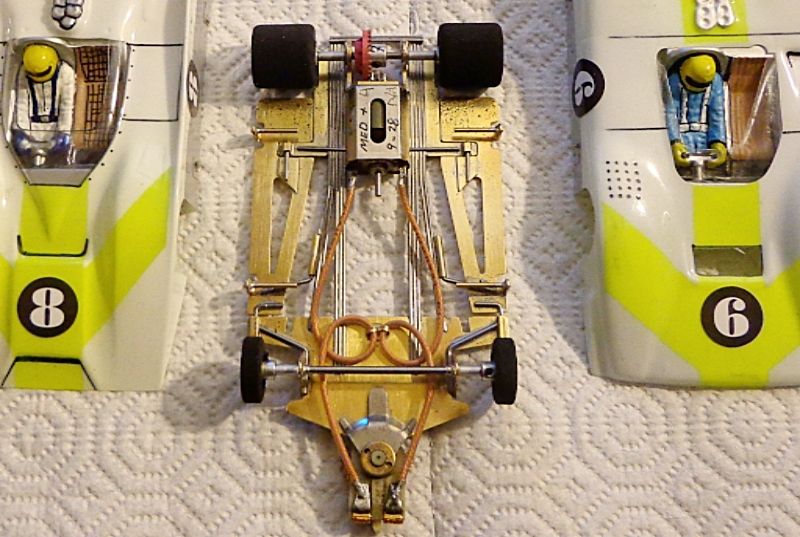

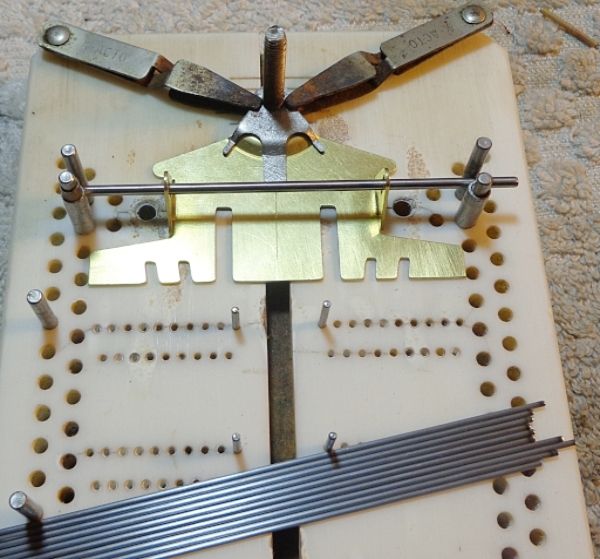

I've been building a ton lately but haven't done any kit builds so when this chassis kit showed up, it was a total surprise and actually kind of a nice break. This will take me a couple of installments because my summer vacation is over and I'm back working some. This will be a pretty conventional 10-rail (five per side) with three straight and two angled rails per side.

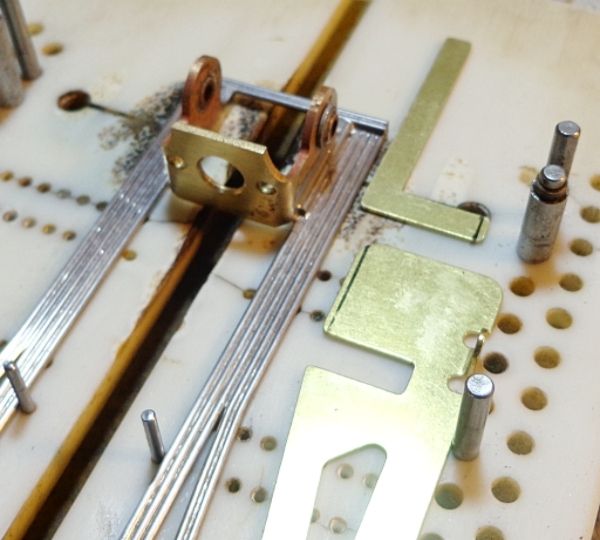

Here are the parts laid out on my granite flat block. Bracket is 3/4" X .050". All the rest of the brass is .032".

- I have already drawn in the lines where the pans will be cut off the nose.

- I cut the pans off right away so it's easier to make the nosepiece flat without them.

- Get the nosepiece sitting dead flat.

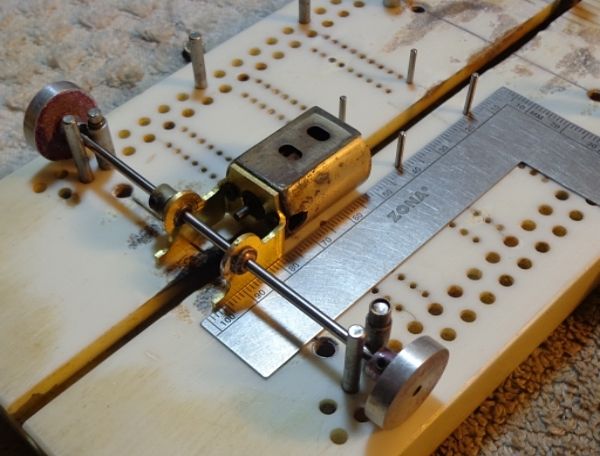

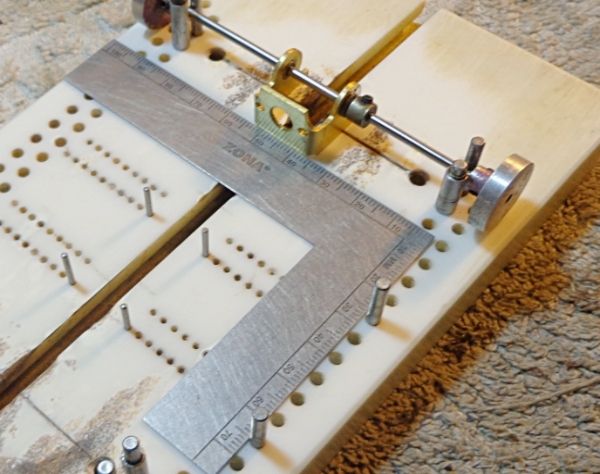

- Square up the bracket face and sides so the face is flat and square to the side legs.

- Get your building motor screwed in and building oilites ready.

- Lay a straight edge against a pair of locating pins set at 3/4".

- Line up the side leg of your bracket against the square.

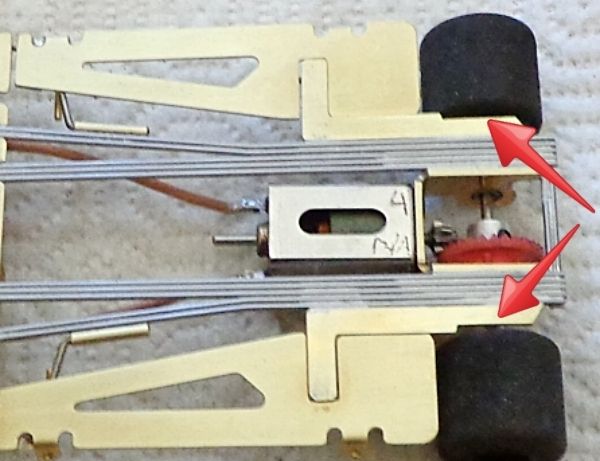

- Get your jig wheels on and then slip the oilites along the axle and into the bearing hole.

- The oilite must slip right into the hole with no drag. If the hole is not qutre right, enlarge it just enough.

- Lightly tack solder the oilites.

- Now the big test. Take your motor out for a sec and check that your bracket face is square.

- If so, on we go. If not, fix it now because it'll be harder later.

- Check your guide tongue for your desired upward tilt. I like about .012-.015".

- Check the fit of the steel guide tongue reinforcer. The GTR must be flat on the brass guide tongue.

- Make sure that the support legs of the GTR don't hold it up or at the wrong angle.

- Solder well. I usually use a torch for this job.

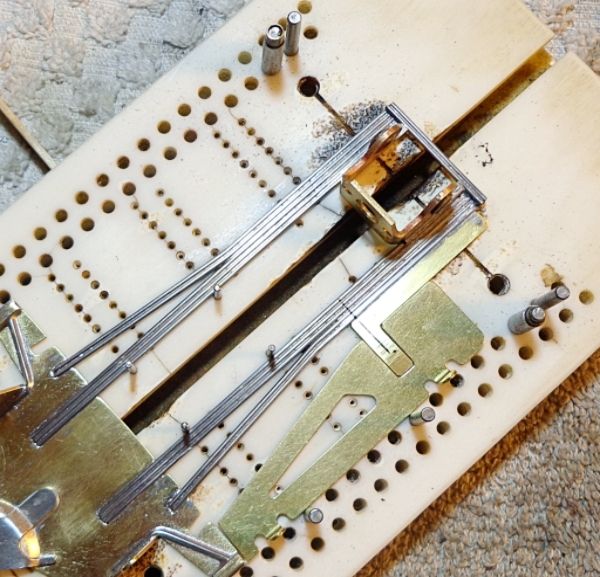

- There's a gang of 5" pieces of .047" wire waiting to become frame rails.

- Take three of your bits of wire and hold them flat and solder together full length.

- These bundles become your main rail sub assemblies.

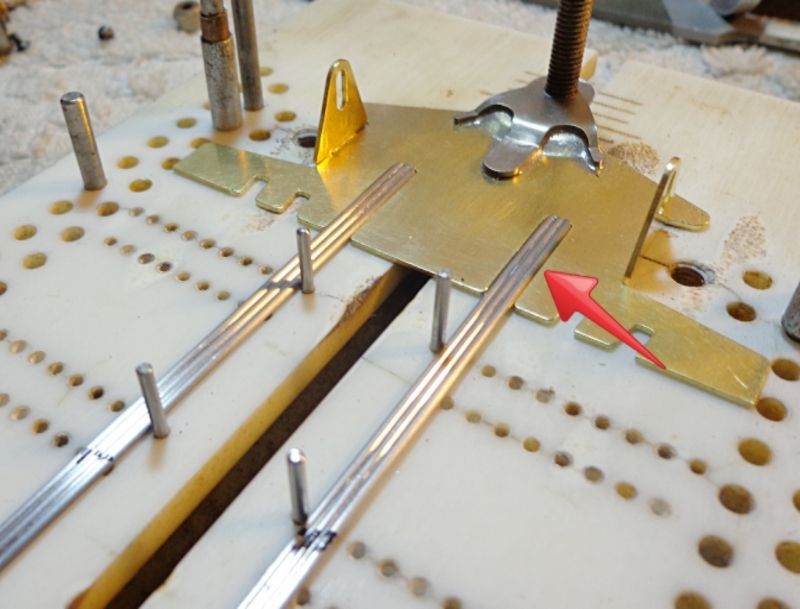

- After the bundles are done clean them up then trial fit into the pre-cut slots on the nosepiece.

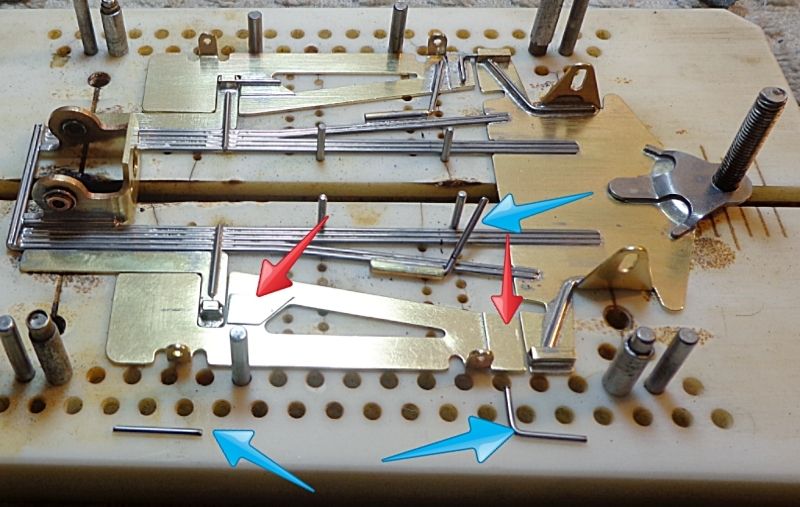

- You want the bundles to drop right into the slots while being held square by your location pins.

- On this one, the right rail bundle didn't go in quite flat so a little file work was done at the red arrow.

- Once the bundles slip in easily, solder them up.

- This is a good time to check the fit of your pans and rear pan support blocks. These will need some trimming.

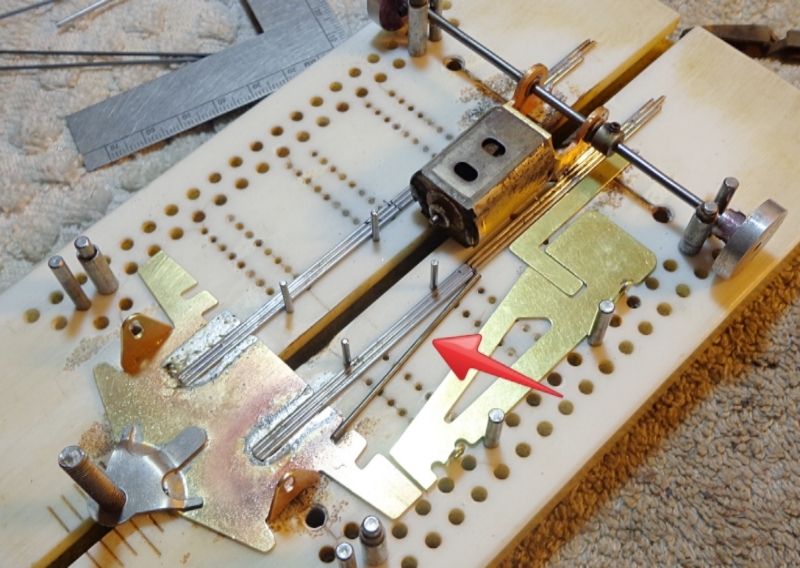

- The main rail bundles and also the angled rails will run wild at the back. They'll be trimmed later.

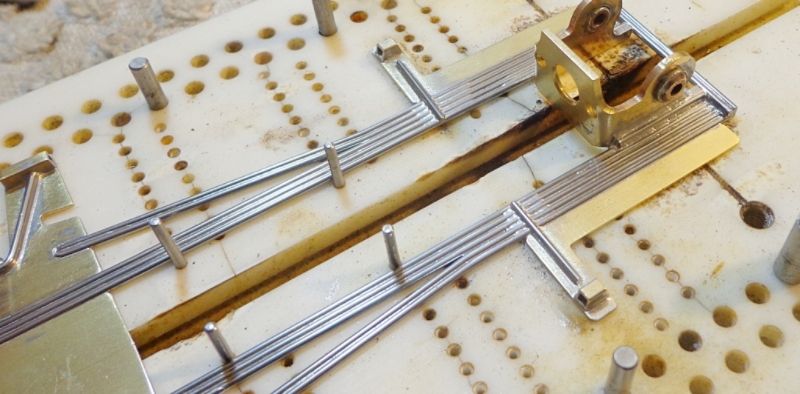

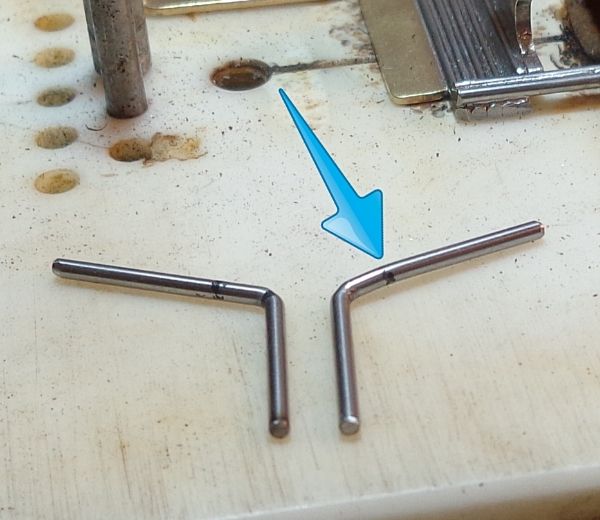

- There is a little bit of wire (arrow) that I'm using to figure out where the angled rails intersect the mains.

- Bend your first angled rail and fiddle with the angle until it's right.

- The rear part lays flush against the mains and the front part goes to the inside edge of the cutout.

- The second angled rail is the bent to match the first. It isn't right until it matches without pushing it into place.

- This build is using the inner slots for the angled rails but of course, the outer ones could be used instead.

- Once the rails are perfect, solder them up then do the other side.

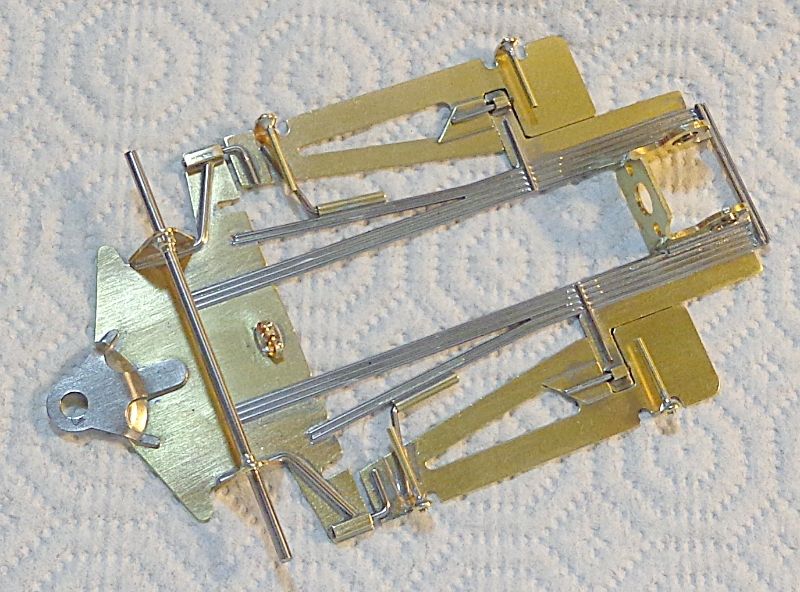

- There will be two bits of .047" wire laid across the tails of all the main rails at the rear of the bracket.

- Those are soldered up then the excess of the rails is cut off.

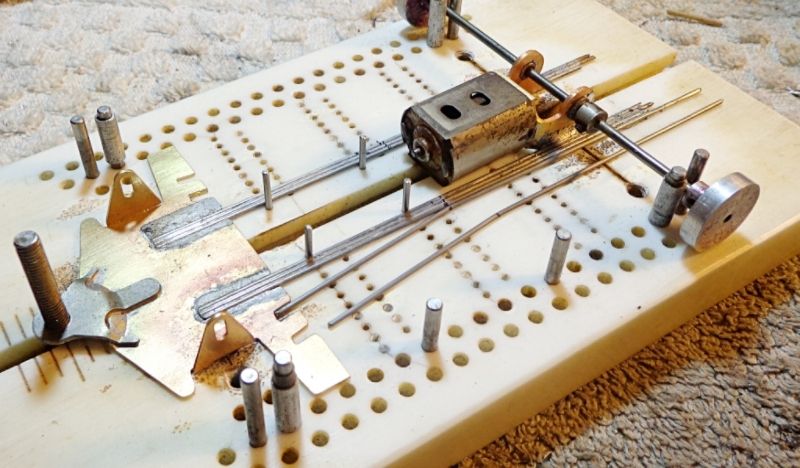

- OK, clean your solder joints of flux gunk and examine each joint to make sure there are no gaps.

- Put it on the flat block and check all four corners for dead nuts flat.

- It's pretty easy to make sure that it is flat now but becomes harder when the pans are on.

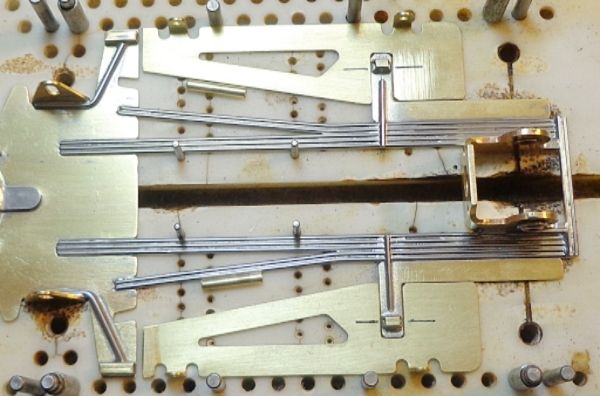

- The cross braces are in place at the rear of the bracket and the rails are trimmed.

- Some .047" wire is soldered in place to reinforce the nosepiece ears.

- A small bit of 3/32" OD box tubing is soldered in place outboard on each ear to capture the pan stops.

- Bracket reinforcement (took this pic after the pan supports went on - will cover that tomorrow).

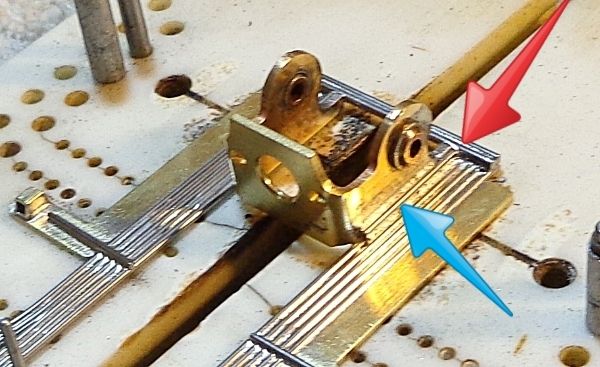

- Red arrow = two bits of .047" soldered across the main rails.

- Blue Arrow = One bit of .047" forming a fillet that reinforces the junction of the bracket and main rails.

That's all I can do tonight. Will finish up tomorrow and hopefully test this weekend.