I get PMs from people looking for projects they can dig into for not much dinero, and I most often tell them to look at some of the Mabuchi motors being sold today for industrial uses such as automotive accessories... car door lock and mirror actuators. After that, I'll tell them to look for motors with 2mm shafts and of a size that makes sense for slot cars.

Slot car racers did the very same thing waaaaay back when they looked for motors either from other hobbies (model railroading) and industry. So, this is a continuation of that exact aspect of early slot racing. As dedicated slot car motors from various manufacturers made all this unnecessary, people didn't need to go scrounging, and they could (if they wanted to go faster) just rewind/modify slot car motors. As the offerings from the manufacturers got better and better, even that became "unnecessary", and people just bought motors or parts off the shelf.

Now, with all things Retro more popular and the really fast stuff having become pretty pricey, there are still ways to have fun cobbling together motors intended for other purposes. The good news is that even "plain jane" motors come with some pretty great parts... most notably magnets, and some of the old "standard" sizes are still out there in disguise.

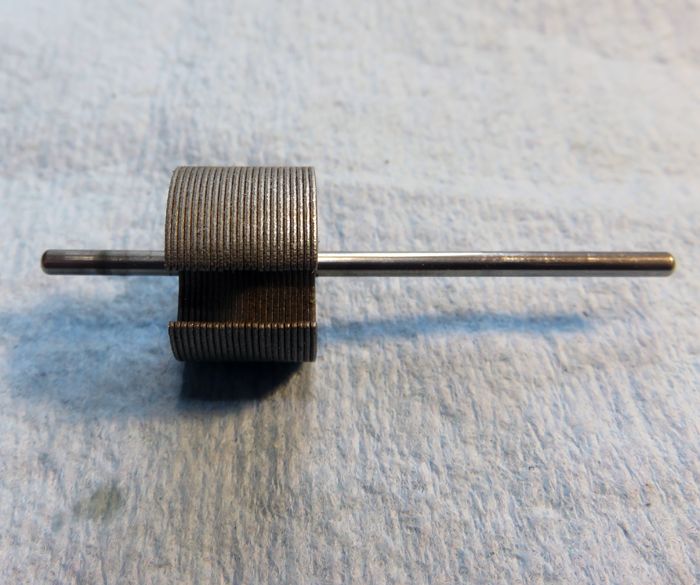

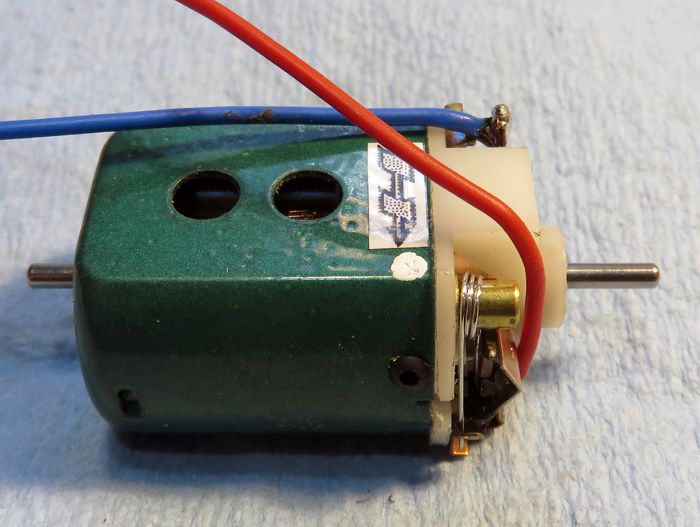

The old Mabuchi 26D has a close descendant in the modern FC280. The height is a bit lower now (a good thing), the length is a bit longer now... close to the Mabuchi FT16D (also a good thing), the shaft is still 2mm (yippee!) and best of all, the magnets are what would have been considered evidence of alien visitations in the early '60s (hip, hip, hooray!). These motors come with a set of ceramics that blow the old 26D Arcos out of the water and in the stock new can (still one piece "drawn") produce a "hole" that's pretty dead-bang perfect for a .590" diameter arm (score another for the home team), which makes sense because the stock new armature is... .590" diameter.

Now for the bummer... or the really good part if you like getting your fingers dirty. They come with an endbell that's not going to work, using very small/thin brush arms sized for the teensy-weensy commutator that comes installed on the armature. The can is only a bit off from the width and height of the good-old 26D though... so why not modify the 26D en bell to make use of such a neat-o can and magnets?

To start, here's the drawing/specs for the modern FC280:

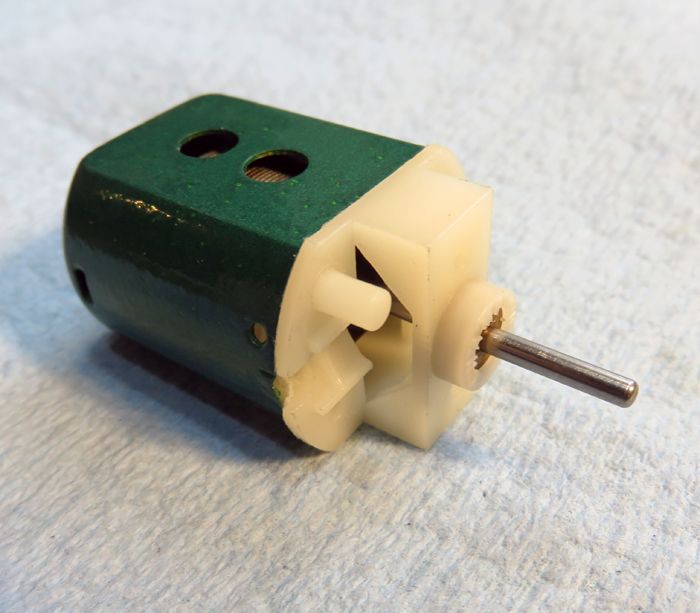

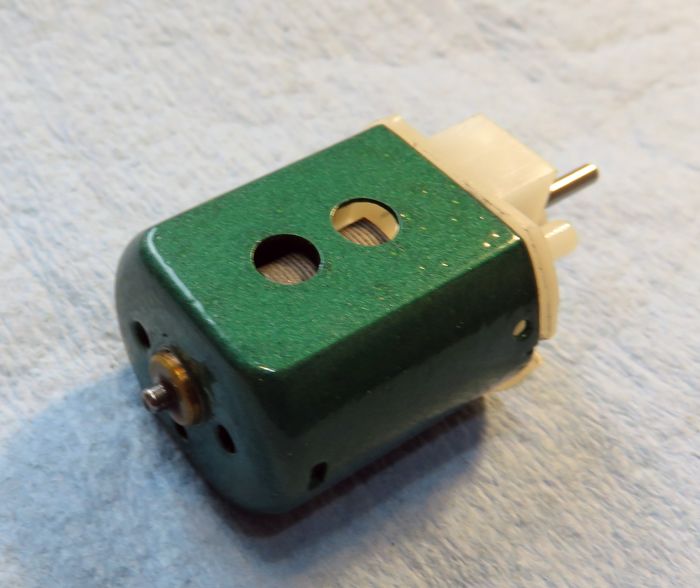

... and here's what they look like (although they come with all kinds of different shaft options... long, short, splined, smooth, whatevah).

Stock, they look sorta like a Falcon type motor that needs to go on a diet, but those motors are really just a different size of the same inexpensive type as the FC280, just spec'd for slots instead of Toyota door locks

There are even dead-ringers for the "Falcon" type "FK" sized motors, although flat-can modern motors the size of FT16D and FT36D don't seem to be around... or at least as much(?). There are full round can versions, but for obvious reasons, those aren't nearly as attractive an option for slots.

For our uses, the FC280 doesn't require "rocket science" to wind up with a motor that will drop right into most cars that would normally use a Mabuchi 26D. More to come.

-john