ScaleAuto Super Car

#1

Posted 03 May 2016 - 03:19 PM

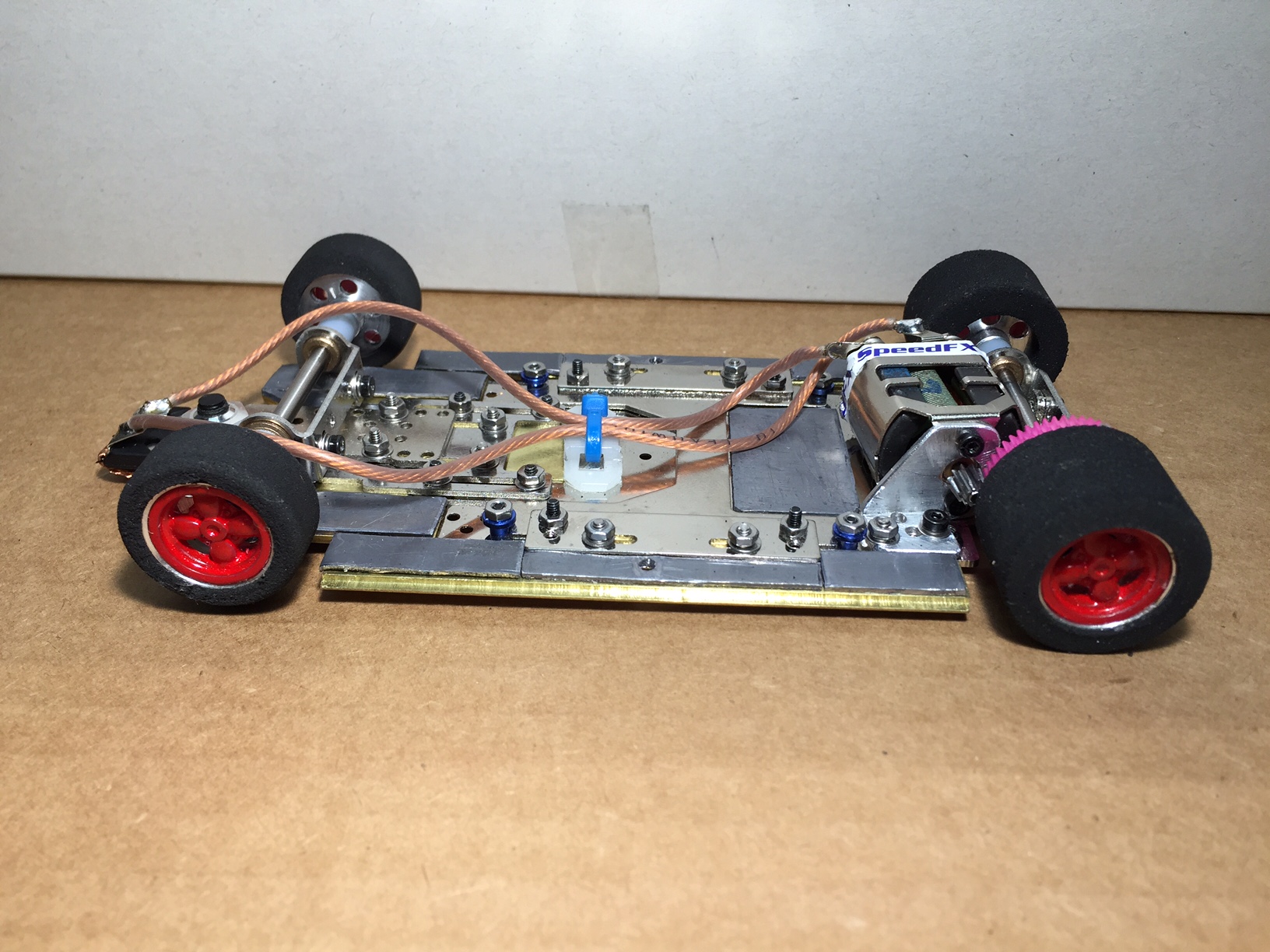

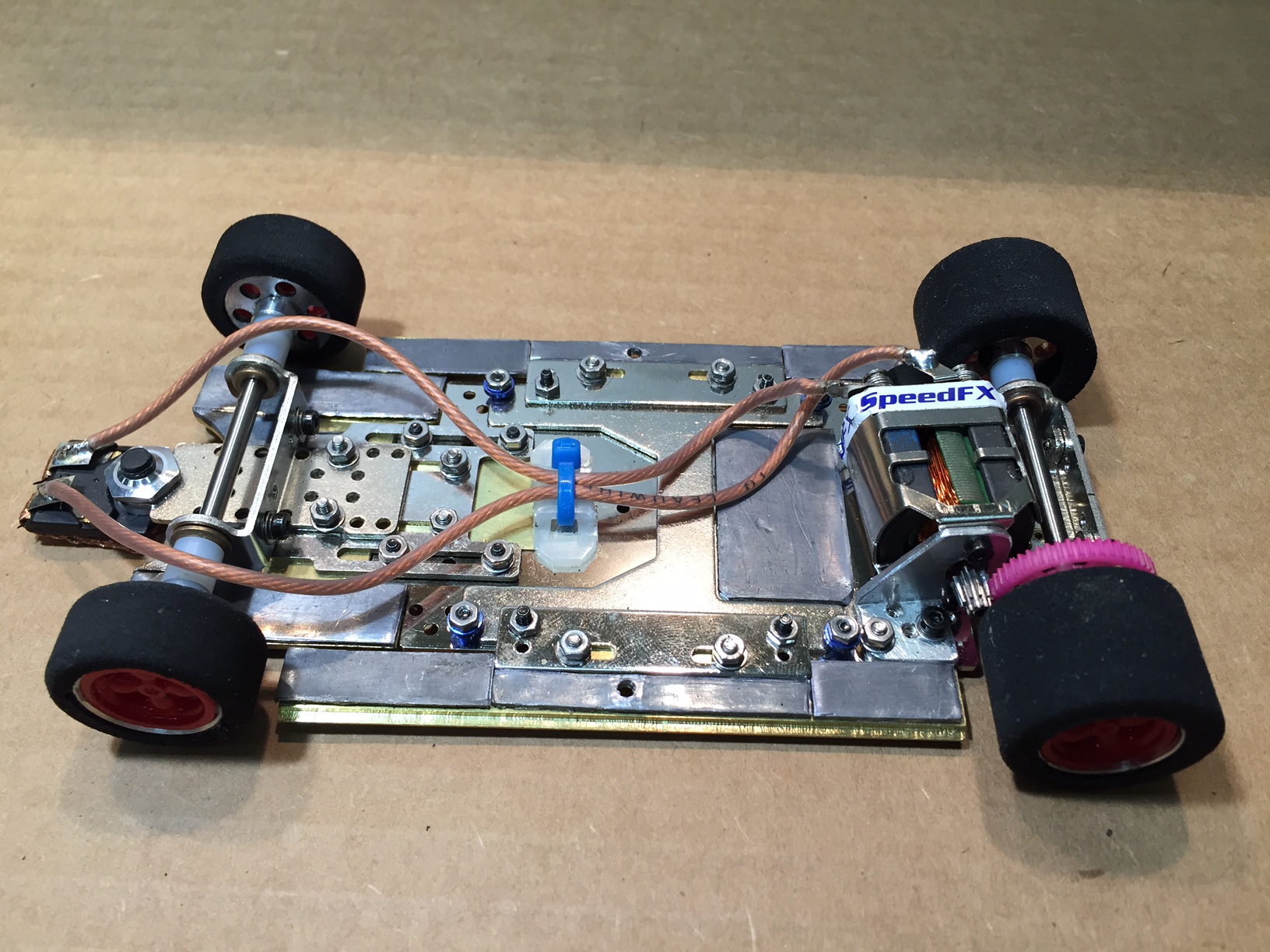

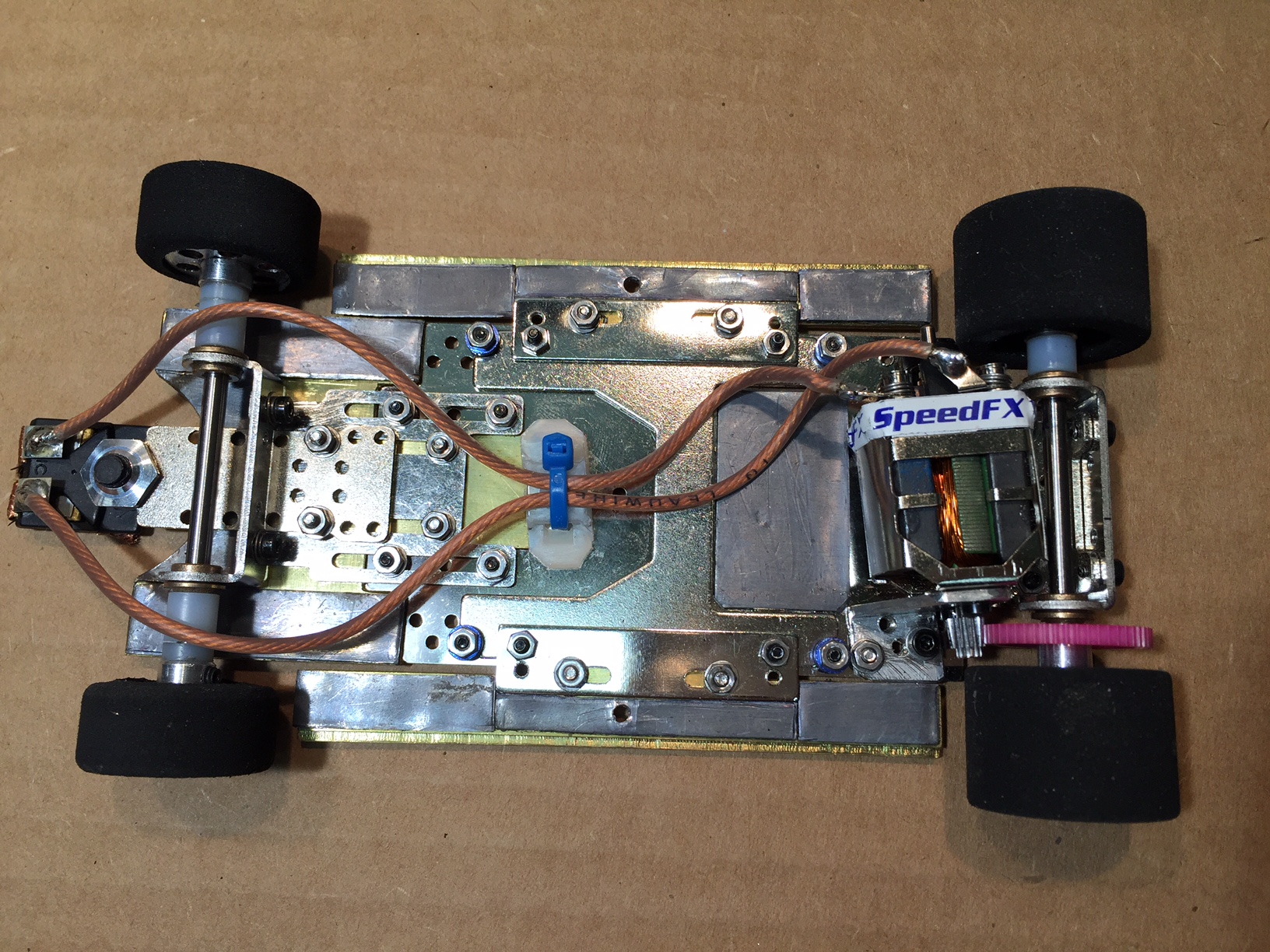

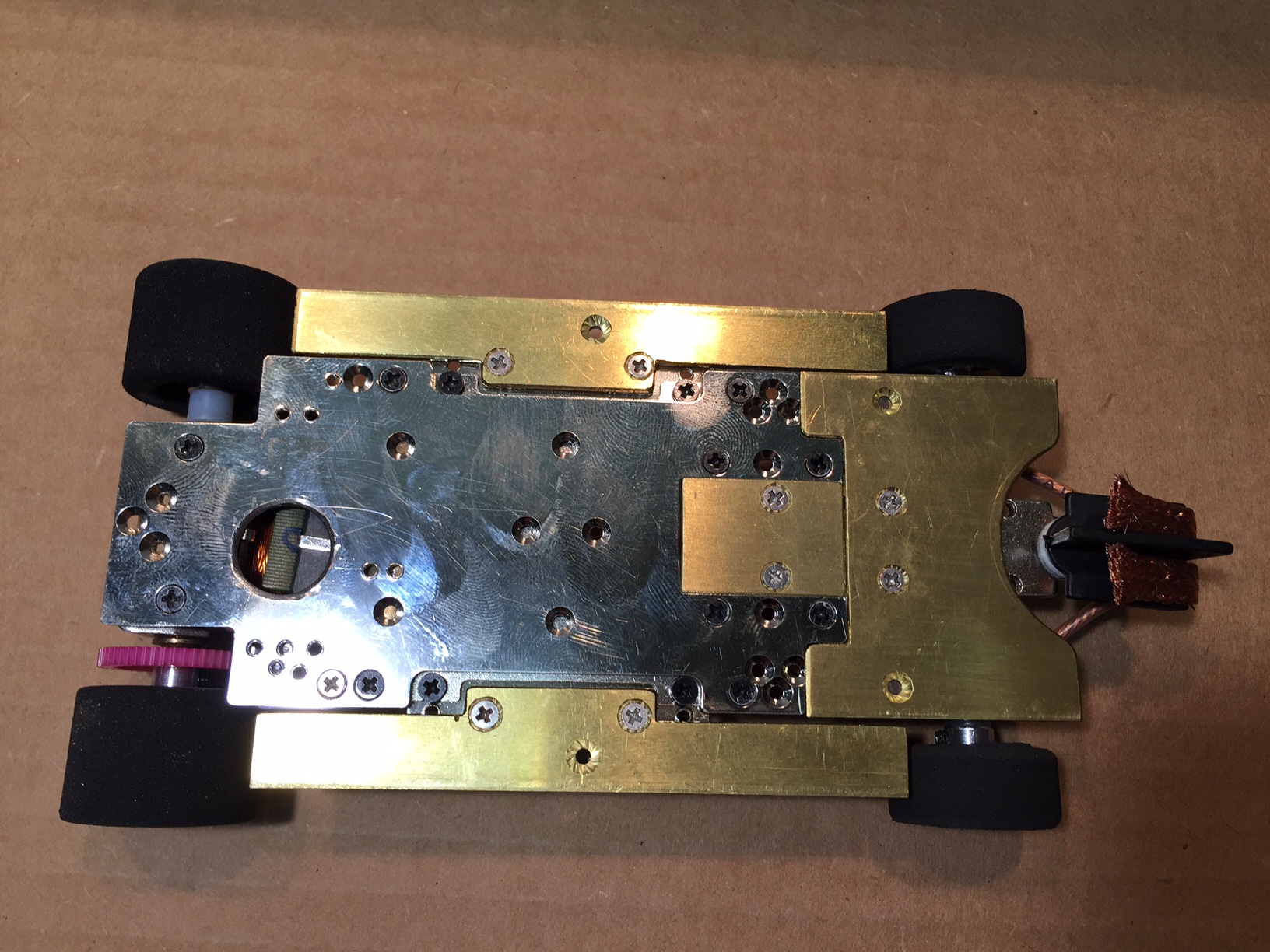

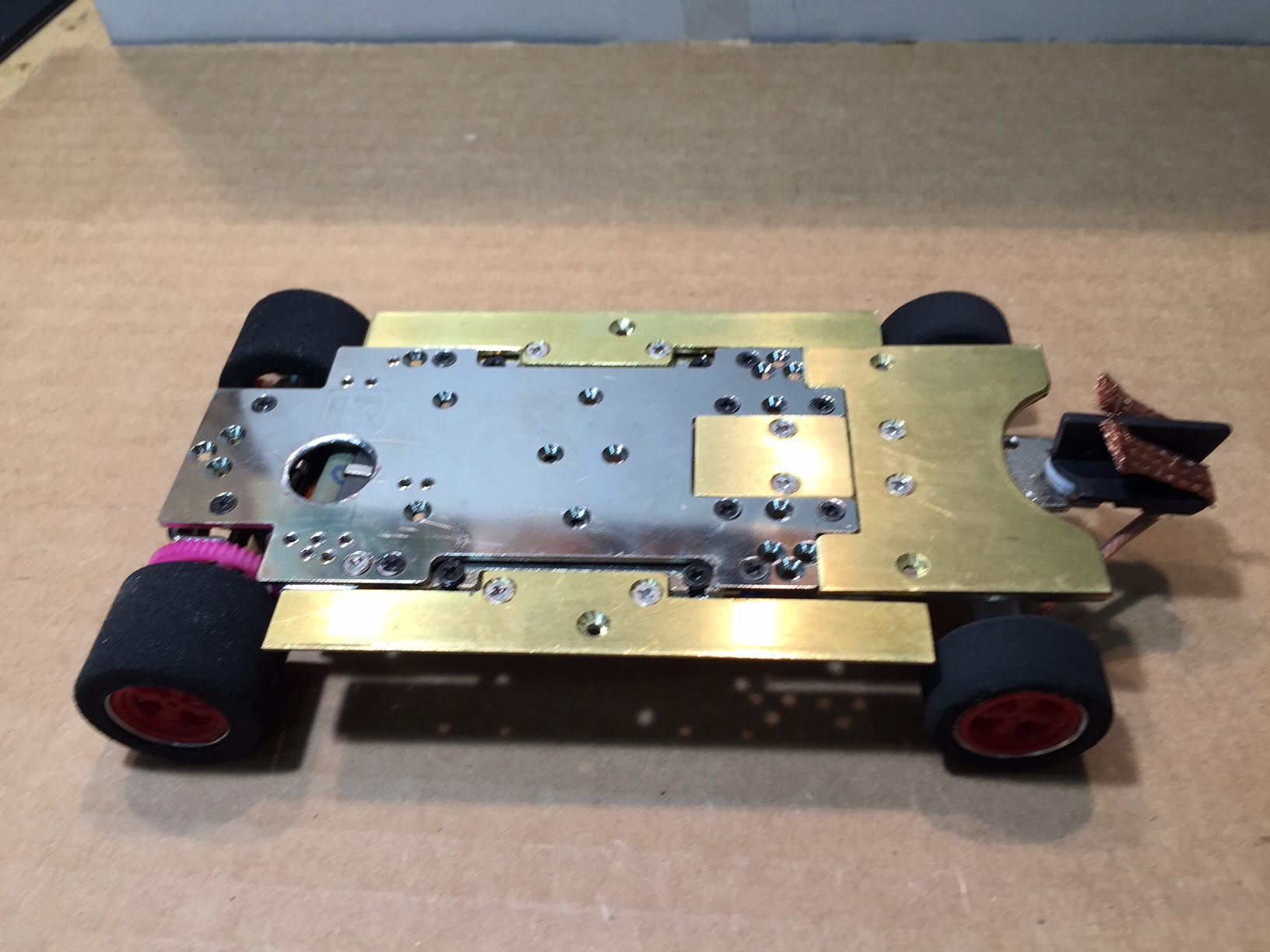

Below are some images of Rons modified ScaleAuto chassis. In addition, the modifications seem to work very well for our True Scale class specification. Our True Scale classes specify either a Falcon/Hawk 7 power plant for GT1 or Deathstar or ProSlot sealed 16D motors for other classes. I know these motors are much more powerful than the standard ScaleAuto motor. In order to improve handling with the very powerful motors, several modifications are made including custom .062 brass side and front pans and associated shims to ensure that the pans are flush with the center section of the chassis; motor cooling hole; custom motor bracket to accommodate the 16Ds. Also, since we use ProTrack sponge tires, we ream out the holes in the axle hangers to accommodate 1 eight inch axle bearings and use a 1 eighth inch axle.

Rich Vecchio

#2

Alexander Blankenship

Alexander Blankenship

Posted 03 May 2016 - 03:25 PM

A couple of questions: How much do these weigh, and how much lead are you adding to these, looks like you could have added more brass .....

Also, why the plastic axle spacers, when you could easily make them out of light weight Aluminum, cut with an exacto knife ?

And , do you guys use springs on any of the screws to simulate chassis torsion ?

#3

Posted 03 May 2016 - 07:03 PM

A couple of questions: How much do these weigh, and how much lead are you adding to these, looks like you could have added more brass .....

Also, why the plastic axle spacers, when you could easily make them out of light weight Aluminum, cut with an exacto knife ?

And , do you guys use springs on any of the screws to simulate chassis torsion ?

Weight about 220 grams (7.8 ounces). Cars heavy because we run very tight tracks with short straights. STR has 8 in radius inner turns. My track, Electron Raceway has 12 inner radius turns. For commercial tracks I don't think this much weight is necessary. Sometimes we use brass tubing for axle spacers. Have not tried aluminum. I am not sure if Ron used springs (of if they were provided), however, I will say that we also use Scholer chassis which have springs to allow front end to float with torsion, but we have found that for our purposes cars are faster without allowing torsion so we simply screw down the front end

Rich Vecchio

#4

Alexander Blankenship

Alexander Blankenship

Posted 03 May 2016 - 07:40 PM

Aluminum spacers cut easily with an Exacto knife, and are much lighter