Not long after the can motors began to dominate slot cars in favor of the open frame or "padlock" motors, people started messing around with them. The whole rewinding thing, magnets, endbells, armatures, balancing, welding etc., are well-documented aspects of the "arms race" that started... and continues to this day.

One aspect of this stuff was the repackaging of the motors themselves. Even though they were popular with enthusiasts for a short while and were available in plenty of RTRs as well, the big cans got smaller and smaller with people also chopping up even the "lowly" 13UO motors and stuffing hot magnets and arms in them. I'm guessing that at the beginning, simply shortening existing motors was an easy way to get more motor into a smaller package, and that even the Mura "Short Magnum" was part of this??? I get a fair number of motors from people that send me "stuff" that look like this Russkit as well:

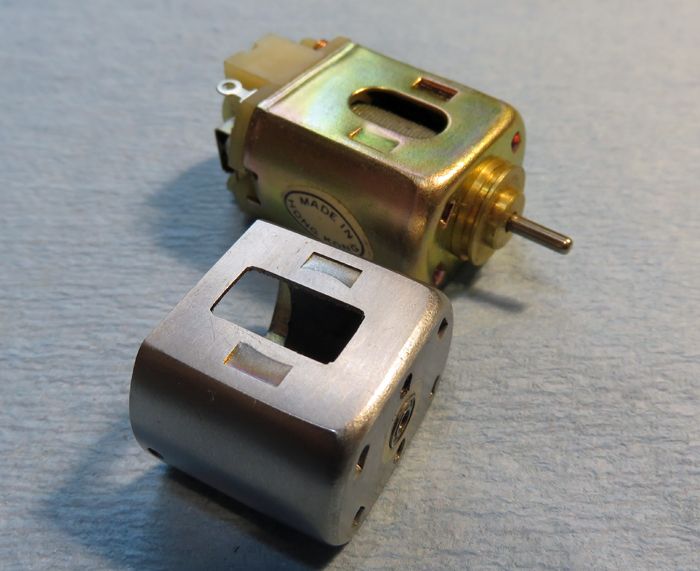

All of this got me motivated (uh-oh!) to step into my virtual "way-back machine" and have at it using not-so-correct parts and do a build. The subject of this build was a perfectly innocent and unassuming Hong Kong-era Mabuchi FT16D. For one, I don't mind screwing with these so much as with clean examples of the earlier Japanese motors, especially the Russkit-type 16D cans. Secondly, I have a fair number of these sitting here, so using one as an analog for the Japanese FT16D just makes more sense, although it presents some "problems" as well:

Like the Japanese models, this one has the huge honkin' can bushing carrier and that just has to go. Also, the can is made from thicker metal which makes cutting it up a "thin cutting disc killer." The bushing end of the can is much rounder and has lumps from forming the metal that (to me anyway) are kind of ugly. I also don't like the oval holes. I don't like squaring them off either, but not as much as I don't like the way the oval holes "look."

So I rolled up my sleeves and got busy (and dusty).

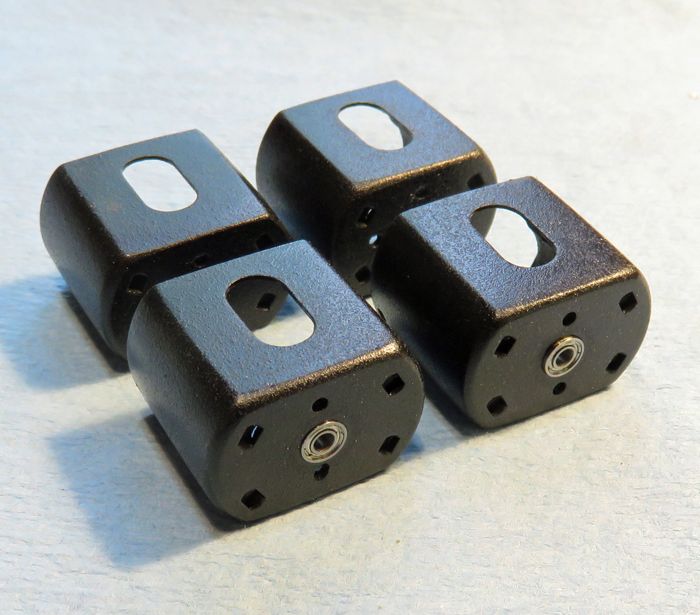

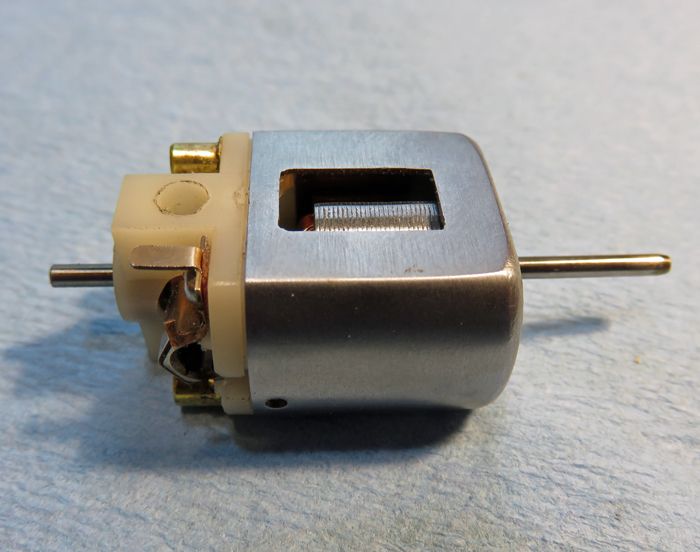

First I had to decide how much to shorten the can. Based on a "go big or go home" attitude (*or maybe... go short or go home?), I chose to shorten the can a lot... like the same length as I do the "walnuts," give or take a few thoudsandths.

Then I flattened and squared things off best as I could, taking down the "lumps" until they were just about flush with the rest of the can, and then working with pieces (many) of sandpaper stuck to my glass work table, I began evening everything out on the flat top, bottom and end of the can. The curved sides I did by hand for obvious reasons. As is always the case over here at "Casa Destructo," if I can't do it with a rotary tool, a hand drill, and various blunt and sharp objects... I can't do it ![]()

Finally, I removed the brass bushing carrier and soldered-in a Champion bushing as a way to fill the giant hole, making sure to boil out the oil... thinning down the inside and sanding the outside flush with the can. Then that was reamed out to accept a 2mmx5mm bearing for can-drive. Of course, I drilled the can sides for endbell retaining screws, and high enough not to interfere with chassis mounting. Oh yeah, I drilled a couple of holes sized for the old Mura endbell screws and spaced "pretty much" the way a modern D motor has them. Are they perfectly straight?... probably not, but they should be good enough for getting this thing mounted. ![]()

... all that was a "stoopid" amount of work, but it got me to this:

Realizing I had a long way to go, I pressed on. Sooo... now I needed a set of magnets, and there's no way either good vintage ones or (gasp) the standard Mabuchis were going in here. My plan was for a large diameter (.560") arm to be sure I could keep the wind to a four-layer coil. I knew there wouldn't be much extra room at the tail spacer (duh!), so a large diameter arm in a D-can means the Parma magnets were an easy choice. Of course... in this can, those magnets would have to be cut down, a dusty bloody mess (... sigh)! Sometime (well, a LOT of time) later, I had them cut and epoxied into the can. Measurements before and after cutting show that the magnets lost nothing at all from cutting in terms of absolute numbers reading around 1,125 or so, although all that "oomph" is now concentrated in a significantly smaller internal area. There's more than a little "faith" involved here because I'm not sure that a reasonable length stack will center in the magnets' field until after all this is done, but the length here is something like I've done before in other motors and I *hoped* things would work out... and they did... whew!

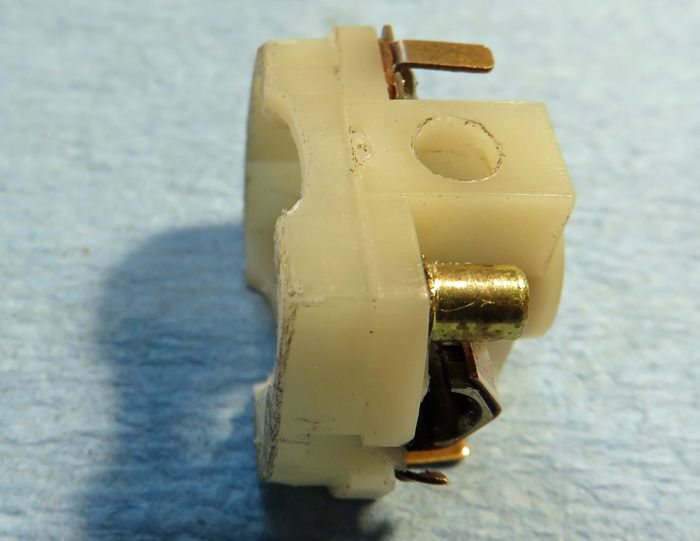

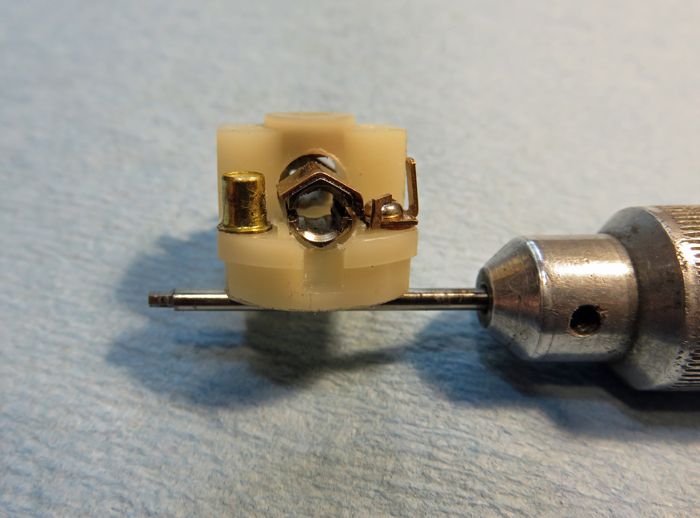

So now I had some endbell "stuff" to take care of. Here I'm using a Champion because... well it's better than both the Mabuchi and the often used Tradeship for several reasons. Right off the bat, the part of the endbell that is recessed to fit inside the can had to be shortened so as to clear the magnets. Also, the top and bottom flat sections of the endbell had to be notched to clear the stack... even after shortening! Finally, I removed some material from under/around the brush tubes so they're pretty much "floating" slightly above the endbell plastic, and soldered the brush tubes ("heat sinks") to the 'pentroof' hoods. Oh yeah, I changed over to "36D" sized tubes so modern standard-sized brushes could be used... easier to get, and they should work better with a larger diameter commutator:

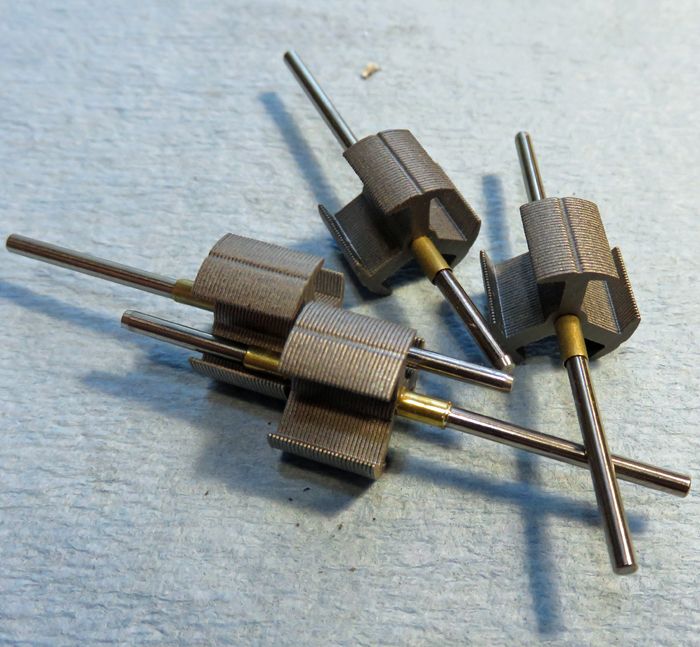

Finally (!), I could build and wind an arm for this thing. As I mentioned earlier, a .560" stack was already a "given," along with a Bugenis comm. The stack length here worked out to just under .400", not too bad by modern standards, and I chose to go with a pretty spicy 42t/28 wind. On this fairly short stack, that comes in at well under .2 ohm... or .185 ohms to be exact. This should be plenty fast and torquey, and still not tax the Champion endbell too much:

Of course, this arm will go out for a light grind and balance, but here's the motor "mocked-up." When the arm comes back, it will just need a bit of assembly type stuff:

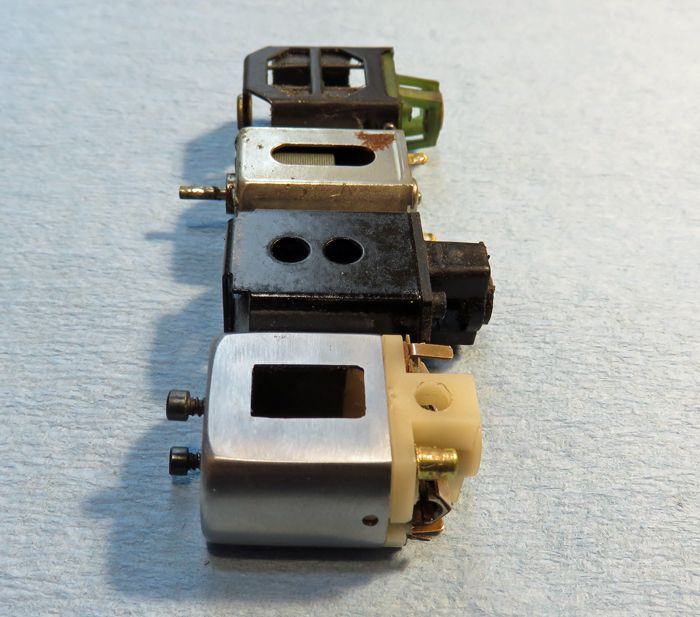

So, how short is this motor? Well, it's way shorter than a C motor, let alone a D motor. Here's a little perspective on this bad boy's length:

Even full sidewinder (much less anglewinder) and with fat rubber, this should go into a car with no problems keeping a "regular" track width.

-john