Best Resistor Controller

#1

Posted 12 March 2008 - 08:24 PM

His reasoning was that instead of spending $83.99 on the new controller, just pick up the 3 ohm wet wound resistor (on hand) and the aluminum heatsinks and cut out the top of my controller for less than $30.

But the Qualifier also has the silver contacts which I cannot find available from Parma separately - it probably makes no difference, but I'm trying to get every little bit I can here. I then began thinking about doing the click relay to it as well.

So before I go through the effort, is there a commercially-available alligator clip resistor controller on the market that is better than the Parma Turbo Qualifier?

Levittown, PA

Home Track: The Race Place - Flemington, NJ

Class: Novice A, 16D, Flexi 1 or 2, resistor controllers

#2

Posted 12 March 2008 - 08:43 PM

Chris, are the Professor Motor controllers legal for what you need? If not, then I think the Parma Turbo is your best bet.

I intend to live forever! So far, so good.

#3

Posted 12 March 2008 - 08:51 PM

The wet wound resistor is the way to go if you have to run a stock Parma type resistor. The advantage is that the wet wound resistor is epoxy-coated and this keeps the bands from moving around when the resistor gets hot.

You will not see any difference in performance in using silver contacts in your stock controller, or any other controller for that matter. Keep your stock ones cleaned and adjusted right and your controller will be fine.

The only thing I would suggest adding to your Parma controller is micro-switches for full power and brakes. This will make an improvement.

#4

Posted 12 March 2008 - 09:27 PM

I've heard this said before. Can you please point to a 'how to' or provide some clues on doing this mod?The only thing I would suggest adding to your Parma controller is micro-switches for full power and brakes. This will make an improvement.

Steve King

#5

Posted 12 March 2008 - 09:47 PM

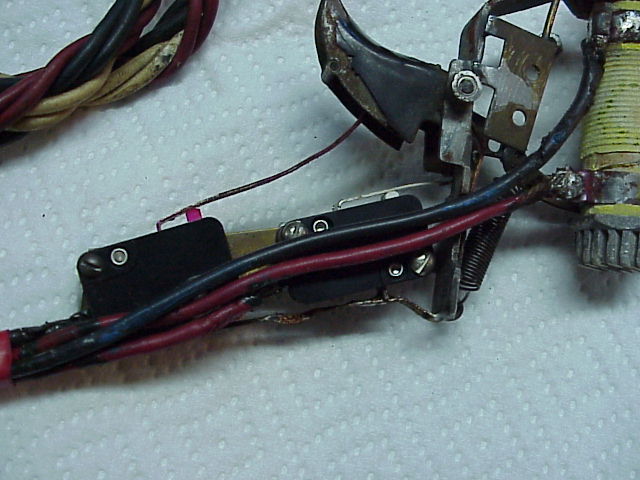

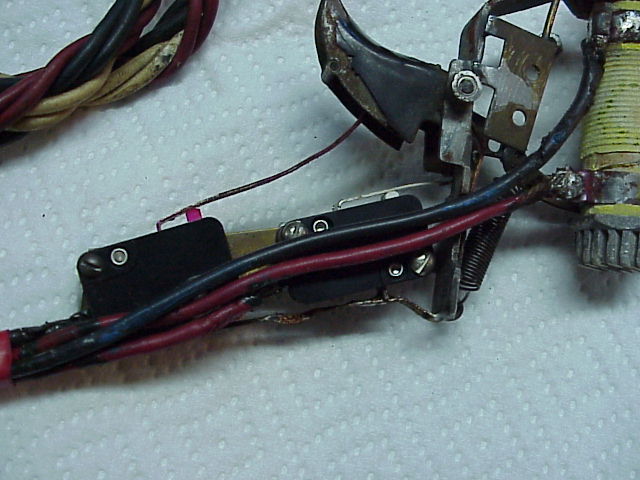

The Parma Turbo controller frame does have the mounting holes "punched" in the frame for micro switches. You will have to get a micro switch like the one in the pics and then line up the holes.

In this pic we see the added brass that the micros are attached to. Note the "arms" coming off the microswitch that appear to be attached to the trigger. Not actually attached, but free and when the trigger is full on, the button on the switched is pressed and opening the switch. When not full on, the button is depressed and closing the switch. Same goes for the brake micro.

In this pic we see the back side and a better view of the micros mounted.

In this pic you can see the red button on the full power micro is up and closed while the brake micro white button is pressed and opening the brake switch. The trigger is in the brake/no power position.

In this pic you can see the trigger in the wide open position and the red button is depressed on the power micro opening the switch. The brake micro is now closed.

#6

Posted 12 March 2008 - 09:57 PM

I assume the full current does not go through the full power micro. Is there a relay as well?

Steve King

#7

Posted 12 March 2008 - 09:59 PM

#8

Posted 13 March 2008 - 12:48 PM

The brake and full throttle contacts in the Turbo accomplish the same thing as the microswitches, and more simply.

If I had one of the non-Turbo resistor controllers, I would put in a relay near the clips, rather than a microswitch in the handle, if I was really concerned about current at full throttle.

The brake micro is questionable. Most people want variable brakes anyway, and putting in a brake pot will likely negate any lower resistance from a brake micro.

Overall, I think finding a Turbo would be a better way to go, if you are going to stay with a resistor controller.

Pacific Coast Hobbies or NCP Hobbies should be able to fix you up, if your local track owner doesn't want to be cooperative in getting you what you want or need.

Steve Walker

"It's hard to make things foolproof because fools are so ingenious..."

#9

Posted 13 March 2008 - 12:55 PM

Ron , thanks for the walk down memeory lane.You asked for it...

This are pics from a late Gorski-modified Parma "economy" controller that was based on the original Russkit controller/tooling and a few years before Parma tooled up the Turbo controller.

The Parma Turbo controller frame does have the mounting holes "punched" in the frame for micro switches. You will have to get a micro switch like the one in the pics and then line up the holes.

In this pic we see the added brass that the micros are attached to. Note the "arms" coming off the microswitch that appear to be attached to the trigger. Not actually attached, but free and when the trigger is full on, the button on the switched is pressed and opening the switch. When not full on, the button is depressed and closing the switch. Same goes for the brake micro.

In this pic we see the back side and a better view of the micros mounted.

In this pic you can see the red button on the full power micro is up and closed while the brake micro white button is pressed and opening the brake switch. The trigger is in the brake/no power position.

In this pic you can see the trigger in the wide open position and the red button is depressed on the power micro opening the switch. The brake micro is now closed.

John Chas Molnar

"Certified Newark Wise Guy since 1984" (retired)

"Certified Tony P Chassis God 2007.2023

Retro Chassis Designer-Builder

#10

Posted 13 March 2008 - 02:12 PM

First Place Loser in the JK Products

International D3 Builders Competition

#11

Posted 13 March 2008 - 03:27 PM

The relay will allow a Turbo to be used with G-12 motors without too much heat. At the G-12 level a full electronic is going to be a better choice. Up to a Super16C motor a standard Turbo will not limit current flow.

A person using a Turbo in the advanced classes does have to not tire of being asked why they don't buy a decent controller!

11/6/54-2/13/18

Requiescat in Pace

#12

Posted 13 March 2008 - 11:53 PM

Parma's website does not say it does.

http://www.shopatron...083.11574.0.0.0

But other sites that offer different product descriptions allude to something like one:

http://item.express....cmdZExpressItem

Levittown, PA

Home Track: The Race Place - Flemington, NJ

Class: Novice A, 16D, Flexi 1 or 2, resistor controllers

#13

Posted 14 March 2008 - 12:11 AM

Does the Turbo Qualifier have a full power relay (WOT relay)?

Parma's website does not say it does.

"Our top of the line controller features an anodized turbo frame, double barrel wet wound epoxy coated resistor with aluminum heat sink and silver plated wiper arm/contact pads to ensure full brake and full power. Smoked handle with nylon trigger and performance 14 gauge silicone wire, includes boots and clips. Use for all 16D, Group 7, Group 12, Group 27 class racing."

Can't see anything in their description about a relay.

Steve King

#14

Posted 14 March 2008 - 10:47 AM

For the racing you're doing now this is all the controller you need or can use:

http://www.e-slotcar.com/products/268

Parma is a little "excited" about the qualifier controller handling a Group 7 motor. After 50 laps the aluminun heatsink might be dripping on your hand.

11/6/54-2/13/18

Requiescat in Pace

#15

Posted 14 March 2008 - 11:18 AM

http://www.e-slotcar.com/products/4974

Very simple and effective. There is a tiny amount of adjustment caused by manufacturing tolerances so a person has to be sure the contacts are "contacting" during WOT. These parts are included on a "standard" $45 Turbo controller and act as an external relay.

This is a very simple controller. Very capable of handling a motor of up to 7 or 8 amps of current draw or a Super 16 C motor.

A person can NOT adjust the resistance (ohms) while standing at the track or lower the braking. That generally requires an electronic controller. And all the associated problems.

11/6/54-2/13/18

Requiescat in Pace

#16

Posted 16 March 2008 - 10:28 PM

This is what used to serve the purpose of a relay for a Turbo controller:

http://www.e-slotcar.com/products/4974

Very simple and effective. There is a tiny amount of adjustment caused by manufacturing tolerances so a person has to be sure the contacts are "contacting" during WOT. These parts are included on a "standard" $45 Turbo controller and act as an external relay.

This is a very simple controller. Very capable of handling a motor of up to 7 or 8 amps of current draw or a Super 16 C motor.

A person can NOT adjust the resistance (ohms) while standing at the track or lower the braking. That generally requires an electronic controller. And all the associated problems.

I've been reading up a lot on this full power relay but I see that inside my controller after retrofitting it with a 3OHM wet wound resistor and aluminum heatsink that there is a full power and full brake contact already there. Should I still do the full-power relay, and/or a full-brake relay?

It is my understanding that the current will follow the path of least resistance so even if the trigger is on the last wiper on the resistor if I meet the full power contact it should go through the full-power contact, correct? And vice versa if I am on the first wiper but touching the full-brake contact?

Then again, looking at it, if I were to hit the full-power contact the white wire is still pinched by the resistor a few inches away...so is it possible some current is still being taken by the resistor? If I were to do the full-power relay modification the white wire is just being used as the trigger wire, correct? So I would want to put the relay as close to the alligator clips as possible?

Also, I am a very tall person, so the stock Parma Turbo controller is really stretched to the limit as I stand to race, I was going to buy the contact set someone linked and some replacement wire to make my own leads...does anyone suggest stepping up to a professional audio grade wire or a larger gauge wire while I am at it?

Levittown, PA

Home Track: The Race Place - Flemington, NJ

Class: Novice A, 16D, Flexi 1 or 2, resistor controllers

#17

Posted 16 March 2008 - 11:57 PM

First Place Loser in the JK Products

International D3 Builders Competition

#18

Posted 17 March 2008 - 05:48 AM

The full power contact is your contact for the relay. You could add a switch to kill the relay for practice, but I love that "click-click" sound it makes. BTW: what classes are you racing with this controller? A stock resistor may be good up to a Super 16D without getting too hot. As for hook-up wire, I use 18 ga wire for my local R/C store. Typically, I like my wires to be 4 ft long & I'm only 5'-7". Just be sure to use copper clips when replacing those wires.

Deathstar only. As soon as I move up to Nascar B, it's the same exact rules except on high power, I can literally use the car as it sits now and make no other changes to it except swap the body to a Nascar-appearing one. And probably a taller gear to compensate for the higher power. Nascar B also allows some electronic controllers.

So even though the controller currently has a full power contact, there is some point to the relay modification? How about the brake one? I'll be real interested to use my multimeter on the controller at WOT now and see what I get before and after the relay modification, that should pretty clearly tell me if I wasted my time or not.

Levittown, PA

Home Track: The Race Place - Flemington, NJ

Class: Novice A, 16D, Flexi 1 or 2, resistor controllers