Maximizing speed through the donut

#1

Posted 01 July 2016 - 12:17 PM

My chassis are competitive and do well everywhere except struggling through the donut. Compared with our singular local "top dog" I'm competitive through the main banked straight-finger-dead man and then I get literally left behind through the donut into the lead on. I probably lose 5-6 feet per lap through the donut.

Going through the donut the car looks like it's "chugging" or struggling. I can't hit full power without a violent deslot. In the black/purple lanes it seems to take forever to get around. Obviously, red and white lanes are much quicker and less of an issue.

I'm thinking I need to start experimenting with narrowing the rear tires. Do I narrow each the same amount? Only the outside or inside tire? How about offsetting the tires one way or the other? I'm currently mounting them exactly balanced and in line.

To those of you who have had success traversing the "donut," what do you suggest? Where do I start to look? I don't want to change too many things at once but I have to start somewhere.

Thank you in advance for your insight and experience.

#2

Posted 01 July 2016 - 12:48 PM

Also, have you seen this thread? Chatter in slo-mo Is what is being shown here how your car is handling?

Yes, you can offset the rear assembly to help in the donut. I did this all the time when I was actively racing. You won't be able to get much but it can help.

Another thought is that a small amount of lead on the pan on the inside of the turn may help. You'll have to test where it should be located in terms of forward or back.

Something else you might try is different tires on the right and left. I'd start with a harder tire/bigger hub on the outside as compared to the inside. That's what usually worked for me, but sometimes it was just the opposite and I can't say why. That's why you test...

Don't ignore the advice given in post #7 in the chatter thread above. Always test guide spacer stack height. Start with what you think will work best and then add and subtract .005" at a time and test. Go at least plus and minus .010" from your 'best guess' setting. Many racers want to know what the braid depth is on a particular track so they can set their cars up on a block on their workbench. I guarantee you that on a wooden track it is not a consistent number; at least, I've never raced on a track where that was the case. It will vary and the only way to determine the best spacer stack height is to test it on the track. I recall many times finding that what I thought would be the best guide spacer height was in fact not.

While writing this I recalled a big race many years ago (25?) in Nashville where my teammate and I chased a chatter problem in our GTP cars for most of the day and finally figured out we needed to adjust the guide height. When we got it right, not only could we punch the donut, we could two-blip that King track on most lanes!

Good luck. FWIW I almost never had to narrow tires, so it was always the very last thing I tried.

- Zippity, SlowBeas and Pat Skeggs like this

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#3

Posted 01 July 2016 - 01:13 PM

So, treated rather than narrowing is the suggested starting place.

I will go back to my treated and experiment with them further. The Wonders I recall as if being on ice with sliding everywhere. I will also check out the suggested post.

- Tim Neja likes this

#4

Posted 01 July 2016 - 01:27 PM

Look at your lead wires. Do they self-center the flag (lead wire too stiff) so hard they overpower the flag when it wants to rotate?

I've seen it happen, a car won't behave through the donut and the guy asked me to build him a new chassis.

"What's wrong with the chassis you have"? When I looked at it, the ultra stiff wires had so much self-center action, it was like spring-loaded. ![]()

Changed to a more supple wire and some simple California Loops, end of donut problem, no need for a new chassis.

Paul Wolcott

#5

Posted 01 July 2016 - 01:30 PM

Oh. And guide depth. I hadn't thought about that as a possible contributing factor at all!

That's why I ask my questions here. Thought-provoking insight is often available.

Thanks!

#6

Posted 01 July 2016 - 02:35 PM

You said you were running the JK Cheetah 11 chassis, but there are a couple versions of it... If you are running the X24, try the X25 chassis, if allowed. I don't recall Eddie's specific rules, but he's usually pretty basic and easy with his rules. On some tracks, the X24 will be easier to drive in the deadman, but harder in the donut, but the X25 is better in the donut and a little touchy in the deadman... My son prefers the X25 on Kings. He feels he makes more time in the donut than he loses in the deadman...

Have you tried asking Eddie for help/suggestions?

Michael Colvin

- Pit dads of the world unite! -

#7

Posted 01 July 2016 - 02:36 PM

Owner says treated tires "aren't needed."

Let me interpret that for you. What that track owner likely is saying: "I don't want to spend the money to stock treated tires."

So, treated rather than narrowing is the suggested starting place.

Yes, although a larger hub diameter will often act the same as a harder tire.

- Rob Voska likes this

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#8

Posted 01 July 2016 - 03:07 PM

OK, I have lots of hubs since I cut my own tires on a venerable (some would say antique) Wright Way trimmer. I have been using only my old Alpha hubs (small diameter) though I have lots of Koford larger hubs. I will cut some on the Koford's and compare. I never really thought about a difference in tire performance due to hub diameter.

I agree tire selection is restricted likely due to the owner's desire to minimize inventory.

I will retest my comparison of the x-24 vs. the x-25. I have been using the x-24 at .3 thickness since it has the longer guide lead and, for me, has been the chassis I was able to be most consistent (meaning deslotted less!) with. I have a couple of x-25 in the .9mm thickness. I stopped experimenting with the x-25 due to it's shorter guide lead and I convinced myself I didn't do as well with this chassis vs. the x-24. I clearly need to revisit this. I have two x-25's...one with a .3 pan (an x-24 pan I adapted to fit the x-25) and another unmodified x-25 at the .9mm thickness center section and pan. Previously, when I was doing this comparison I was re-learning to race after a long hiatus away from slot racing. I have been logging enough hours on the track now that I should spend time comparing which works better for me at this point.

Lately, we have been gearing up for a new class to race...Hawk (just an unmodified, out of the bag kind) motor, antique Champion "turbo-flex" and using a special non-downforce type body. In gearing up for this I have noted the car is actually much smoother in the donut than my Cheetah's. I put this off reasoning that the car is slower (lap times in the 5.2 range by comparison) and have not thought about it. On the outer lanes I can punch in full power in the donut. Again, I didn't think about this because the car overall is so much slower and the Hawk doesn't compare to the S16D. I should be thinking how and why I can be so smooth with same untreated tires and this setup vs. my Cheetah's.

Yes, Eddie (owner) is always very helpful and supportive. However, he likes to refrain from getting too far into the details and encourages racers to find their speed through collaboration and experimentation.

#9

Posted 01 July 2016 - 03:28 PM

Speaking of bite bars, if allowed, try a thinner one.

- Pablo likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#10

Posted 01 July 2016 - 04:13 PM

Re: Wonders on that particular track.

Last Retro race there, I started the C/A race on wonders (Koford Soft). It had been great in testing the week before. Then, on race day, it wasn't quite as good but I stuck with 'em anyway. First two heats were in the gutters with fresh power from having the charger on. For two heats, I was under the bus. Then, as the race wore on and I got out of red-white, my car came around and it was the fastest on the track. Wonders can work and are a sometimes valuable tuning option.

Adding weight, as already mentioned is also a good tool. I don't think I've ever seen a car slow down from adding 2-3 gr. of lead. However, I have often seen that small amount of weight enable a car to go faster.

Also, don't forget, that donut is not a "one stroke" turn. To drive around at one trigger set, you have to go too slow in the first half. If you drive it as a "two stroke" turn, you can go faster. That means hard on it at the beginning, a three-four band micro lift in the middle, and then harder on the way out.

- Pablo likes this

#11

Posted 01 July 2016 - 04:19 PM

I probably lose 5-6 feet per lap through the donut.

I agree with Swiss - my opinion is, that big of a handling issue isn't caused by lack of the latest chassis or fine tuning of rubber compounds.

If it makes you feel good to change chassis or wheels, go for it - it will probably fix the problem. But how will you ever know what the problem was?

The best thing would be to find a racing buddy that can look at your car and diagnose problems.

Paul Wolcott

#12

Posted 01 July 2016 - 06:15 PM

OK so your other car doesn't do this so its not the track. No-one else is narrowing tyres so I wouldn't do that (yet).

Things I would check (in no particular order)

1. Bent axle and/or rim

2. Outside tyre or rim (for that corner) rubbing somewhere on the chassis under corner load

3. Chassis too low, where is it picking up goo? Could be plowing. IMHO should be goo on the tips of the 'wings' only

4. Gearing sounds too tall. We run S16D here - these motors rev quite high - they need to be 10/37 ~ 10-42. Your gearing seems about right for Hawk7/Retro but not S16D

5. Pans hanging lower than the centre section at the back (typical problem easily fixed)

6. CONTROLLER wiper arm contact too light, and missing contact in the middle of the sweep. Under pressure of racing its easy to put some sideways pressure on the trigger, lifting the wiper arm off the contact. depends on what brand you have but this plagued me badly last year until I realised what it was. Was like my car was misfiring.

7. Braids worn/too flat against the guide flag, and making poor contact

8. Worn axle bushing

9. Make sure guide flag is level to the track (or slightly upwards) with your LARGEST tyres. All sorts of nonsense happens if you're riding on the front of the braid not the back

Post some pics of the underside of your (dirty) chassis.

- Cheater, Pablo and MSwiss like this

Steve Meadows

#13

Posted 01 July 2016 - 06:31 PM

Make sure the guide flag is angled slightly up.

Don't be afraid to just bend it up with your bare hands.

Make sure the front of the center section is showing a little rub out on the ends.

You may need to experiment with a cut-down guide or remove a spacer or two to accomplish this.

Make sure you have the body mounted low and as far back as you can.

Use the cut line as a starting point.

Make sure to use as little tape and reinforcements as possible to keep the body light for better handling.

Try a one-piece pan on the C-11 or an X-25 chassis.

The natural rubber tires shouldn't hurt the car in the turns.

#14

Posted 01 July 2016 - 06:58 PM

Very detailed.

I would doubt it's number 6, if it's only with one certain car, and in only one turn.

But it can't hurt to throw out the possibility.

I borrowed a light wiper contact controller from a friend, and I would occasionally lose power, until I remembered he was a lefty, which naturally pulled the wiper arm a bit more towards the wiper block.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#15

Posted 01 July 2016 - 07:03 PM

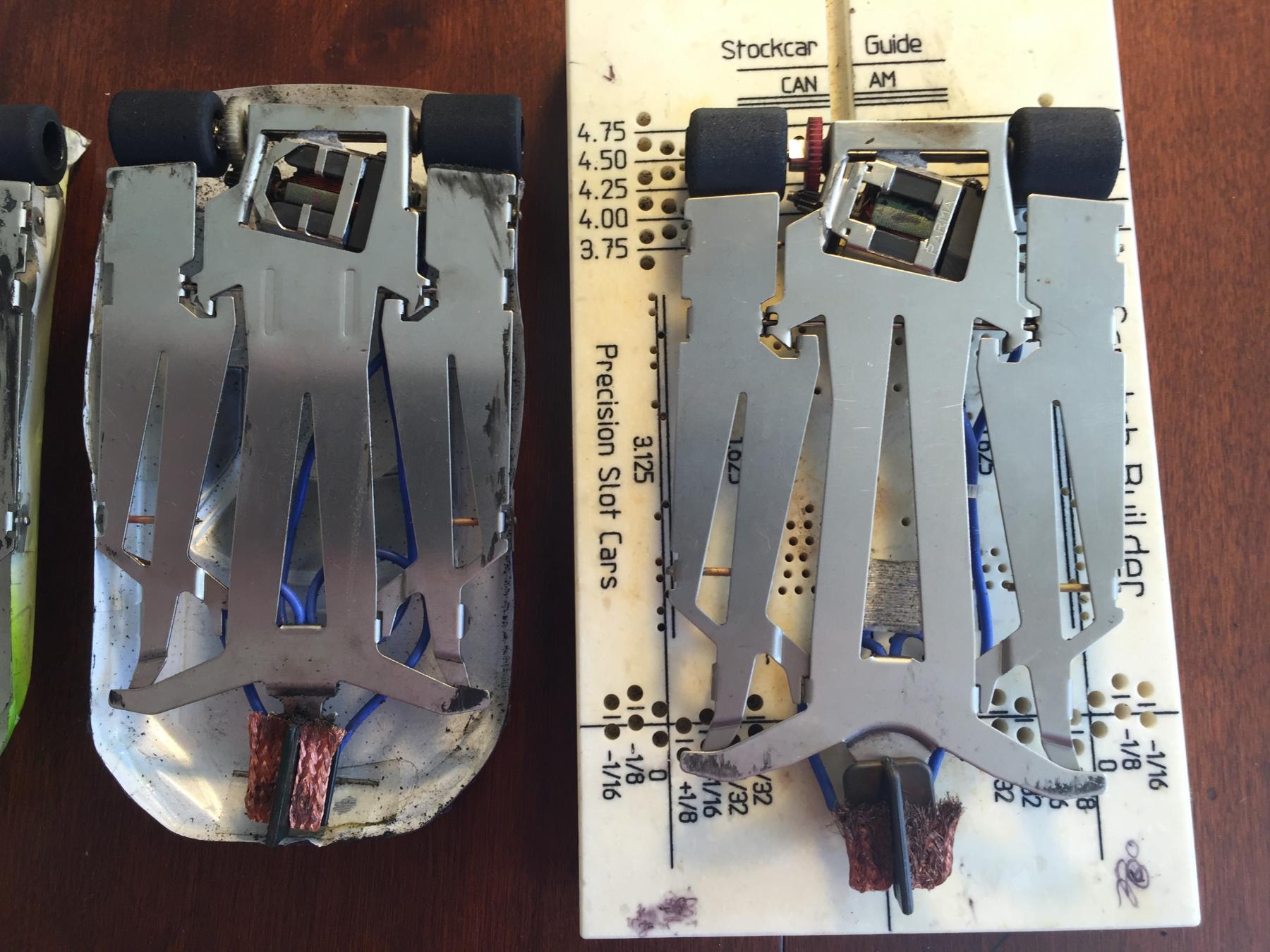

Here are some photos to challenge your diagnostic talents.

I'm currently operating three X24s. The ones I tend to race most often are in the photo side by side. These are in their appropriate bodies. I haven't cleaned the bottoms since my last outing.

The third X24 car is next to the X25 (no body). The X25 that is going to get another look is reclining on the Scratch Builder block.

#16

Posted 01 July 2016 - 07:09 PM

The lower left car looks like one (no rubber) ear is bent up.

Or possibly the other is bent down. Lol

Also, unless you are on real short tires, on a few of the chassis, it looks you need to add bulletproofing to the center section, under the bite bar, to hold up the pans better.

- John C Martin likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#17

Posted 01 July 2016 - 07:16 PM

Lower left was the second place car last night with 265 laps vs the winner at 280. Not even close. I got smoked in the donut time after time after time.

It may have gotten bent somewhere along the line but I effected no attempts at repairs last night. Or I might have taken a blob of rubber off with my nail on the way to the box. I can't remember.

Anyway, motors are all S16D arms but have endbells cranked to max advance. Two Pro Slot cans, two antique Parma "twisters" Monty built for me long ago.

#18

Posted 01 July 2016 - 07:29 PM

Along with uneven/too much rubber in the rear, it looks like you are getting some wear or burning on the front of your braid.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#19

Posted 01 July 2016 - 07:32 PM

#20

Posted 01 July 2016 - 07:33 PM

#21

Posted 01 July 2016 - 07:36 PM

Yes, looks to me like its slammed too hard on the deck front and rear, and riding on the front of the braids. And I wouldn't run that gearing. Fix those four and I am sure it'll be much better.

Steve Meadows

#22

Posted 01 July 2016 - 07:59 PM

+15 degrees, not %.

Sounds like way too much to me. You might lose blade to slot penetration with that much.

IMO, a few degrees, with full size tires. It will increase with tire wear.

- swodem likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#23

Posted 01 July 2016 - 09:43 PM

If you're racing these chassis I would definitely recommend you get one of these tools: Triggerman Tongue Tweaker (even if Scott can't spell tongue.)

Here below shows a chassis that's like yours (pointing down) slightly. It should be about the same angle in the other direction with tyres on.

Use the tool and an engineers square to test, and then lever it to the right angle.

Steve Meadows

#24

Posted 01 July 2016 - 10:02 PM

I have to tell you all how much fun it is to tap into this stream of knowledge and expertise. Best wishes and Godspeed to you all.

#25

Posted 02 July 2016 - 11:01 AM