I posted on the R-Geo chassis plate in stock car configuration some time back. That was the .040 version. This will show some details of a hardbody build using the .050 plate. I didn't do the step by step b/c I didn't think of it at the time but the build itself is pretty straightforward. The details involved will be the focus here rather than the mechanics of the build.

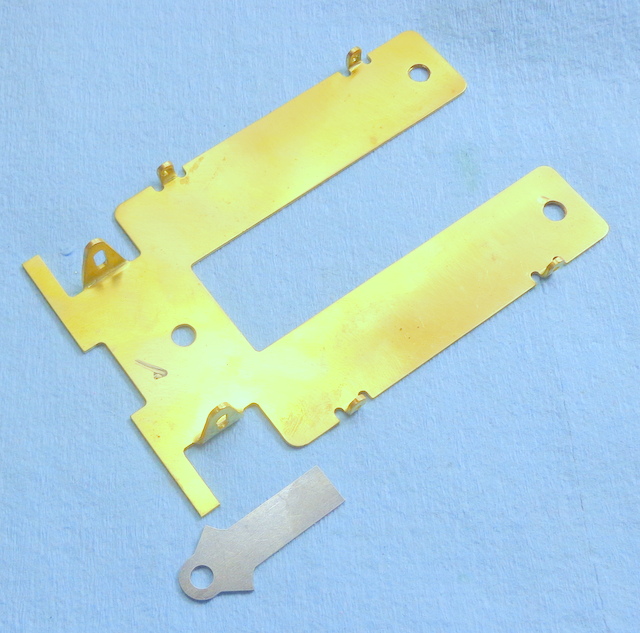

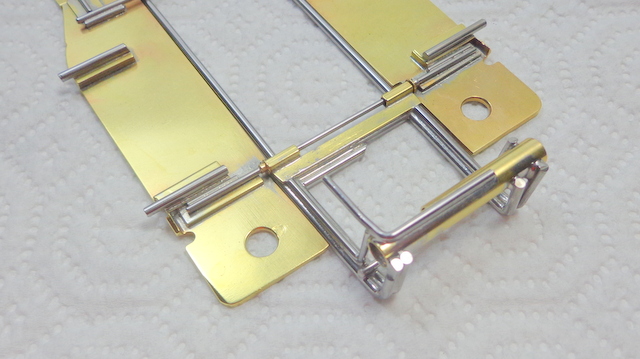

Here's the start point, the R-Geo stock car plate in .050. This pic shows the steel R-Geo guide tongue but in this case, I used a Warmack tongue with some offset built into it.

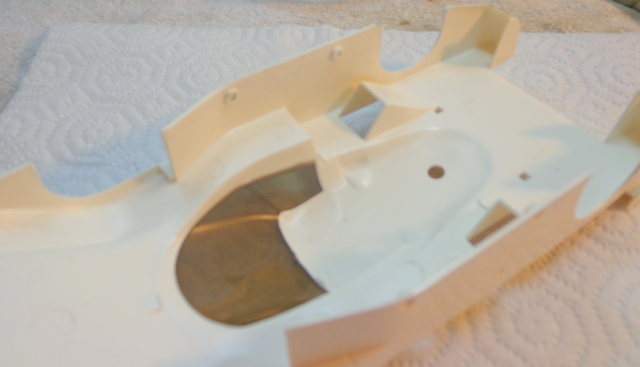

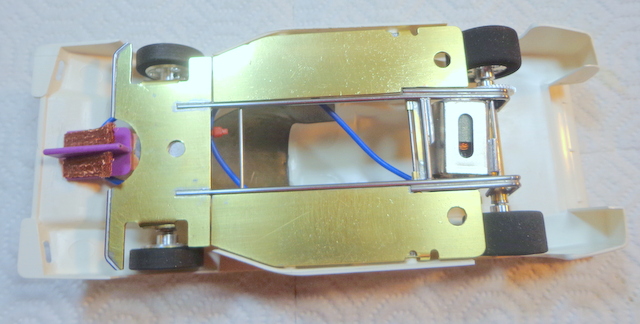

This shows the Tamiya TamTech (BMW GTP) body upside down so you can see a few of the idiosyncrasies.

- Dang white on white picture is cruddy.....sorry about that!!!

- This body is BIG and the chassis will have a 4 1/2" wheelbase.

- The body mount holes are already molded in place so I have to match those.

- The lower body panels have a scoop molded in that I'll have to build around.

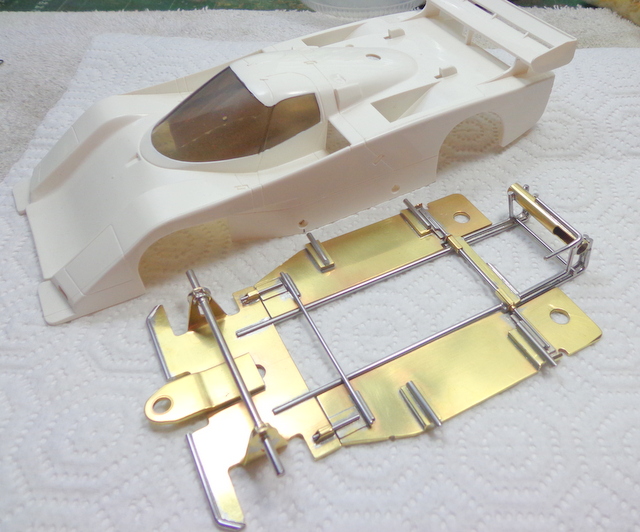

Finished (almost) this is to show how the target build coalesced.

- Single .078 main rails

- Shaker style pan setup.

- Body mounts are .078 wire on top of standoffs to match the height of the stock holes.

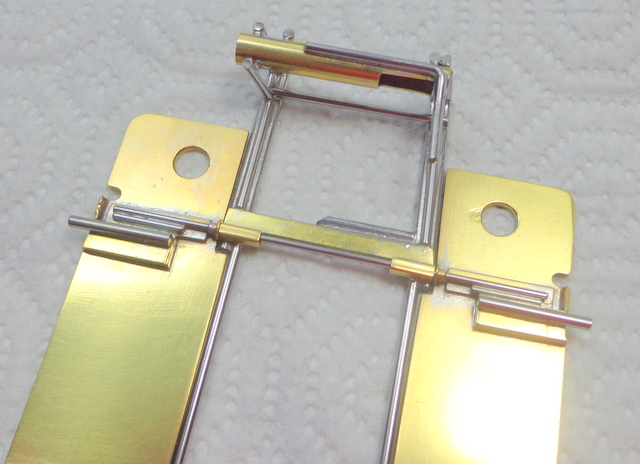

OK....details.....front.

- Main rails notched into the plate.

- Plate is contoured to match the shape of the body.

- Spreader bar of .055 wire on standoffs to match the main rail height.

- Shaker controls of .047 wire in 3/32" tubing.

- These wires are on .015 brass standoffs to match thickness of front plate plus the box tube.

- Axle uprights are cut out so that the axle can be raised to accommodate .975" fronts.

Details......rear.

- Motor angle about 5* to match angle of pinion and allow more flexibility than full sidewinder.

- Half rails of .078 coming forward to just the front of the motor box area.

- Front rail of motor box is .078.

- Top plate tying motor box together is .032 X 1/8" brass.

- Small bit of .078 wire at front of motor box to give a solder point for motor (if desired)

- Top motor brace is .062 wire and is really a "tack point" for motor positioning.

- Rear shaker rod and brace are .047 wire on appropriate standoffs.

Finished (almost) with running gear in place.

Motor installation:

Body mounted and guide flag re-positioned after I discovered that I'd made the guide lead too long to fit under the dramatically sloped nose on the body......... ![]()

And.....ready to go off to the end user.