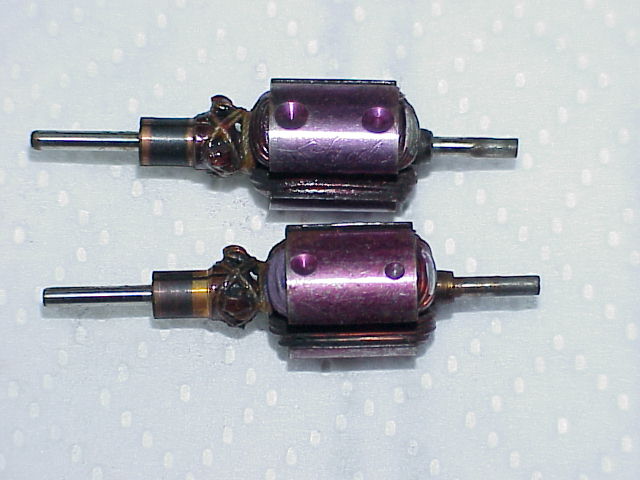

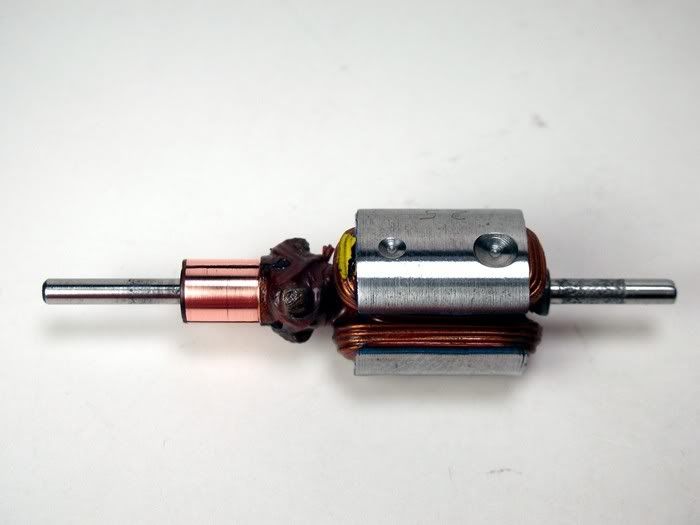

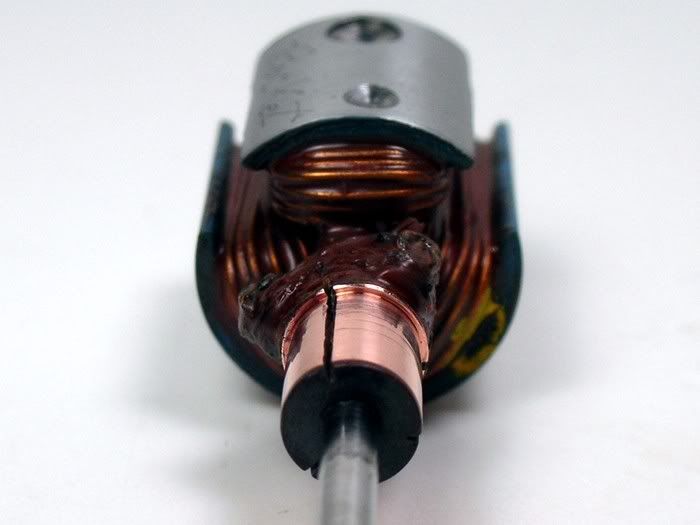

OK, it's a Rocket S25. It measures .2 ohms and seems to be in good shape except for this corrosion on the shaft where it will ride in the bearing. I'm thinking I could use a ball bearing to ease the shaft's pain. I was also thinking about securing the shaft to the ball bearing with a dab of Loctite. That way the pitted shaft is locked to the ball bearing and the bearing is doing the work. Any opinions about doing this

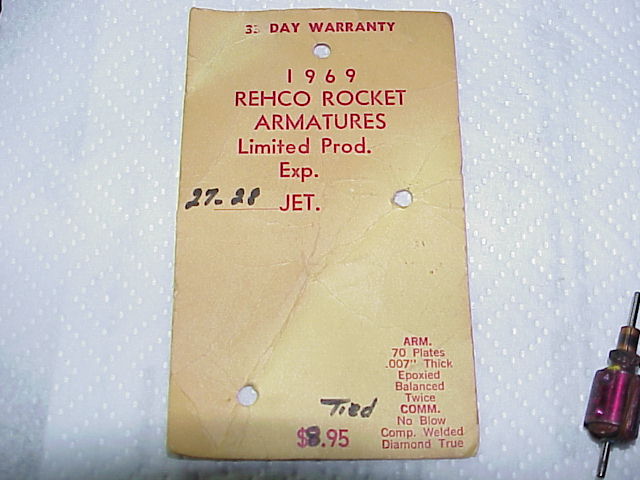

I did a search and found this about Rocket by Jim Honeycutt:

So can anyone help me with:Might be a Rocket armature from Linstedt/Wittenaur. They were epoxying & tying for really hot power on the Midwest tracks. The arms were practically indestructible, but sluggish on mild power.

A time period for this arm (early to mid-'70s???)

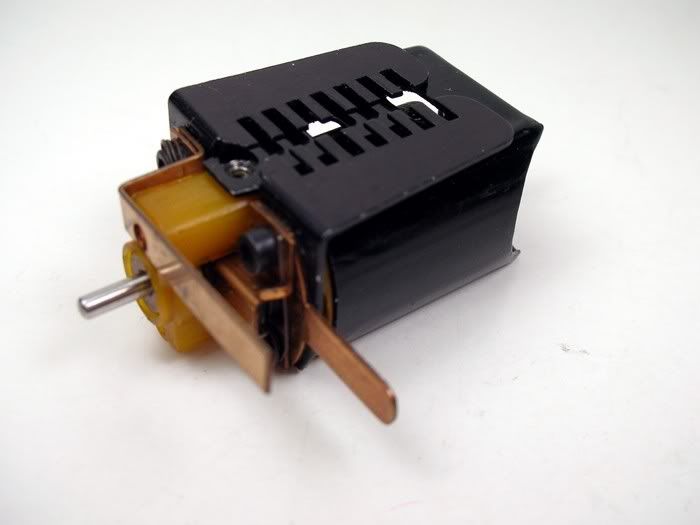

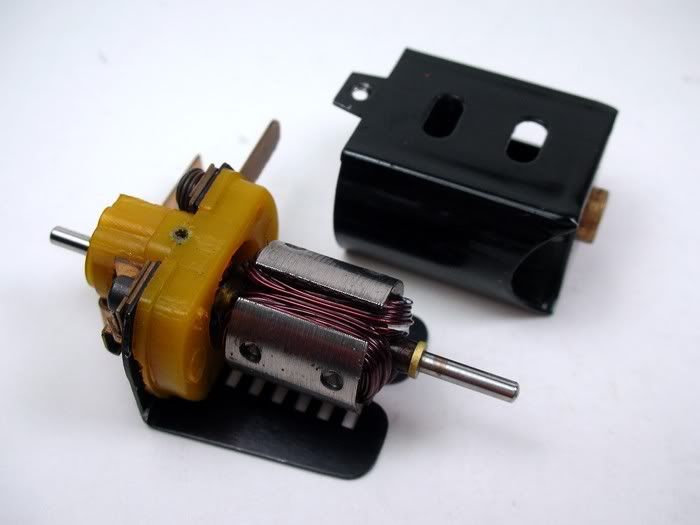

Did Rocket make complete motors?

What type of setup would this arm have been used in? Mura two-hole C-can?

Any info would be much appreciated.