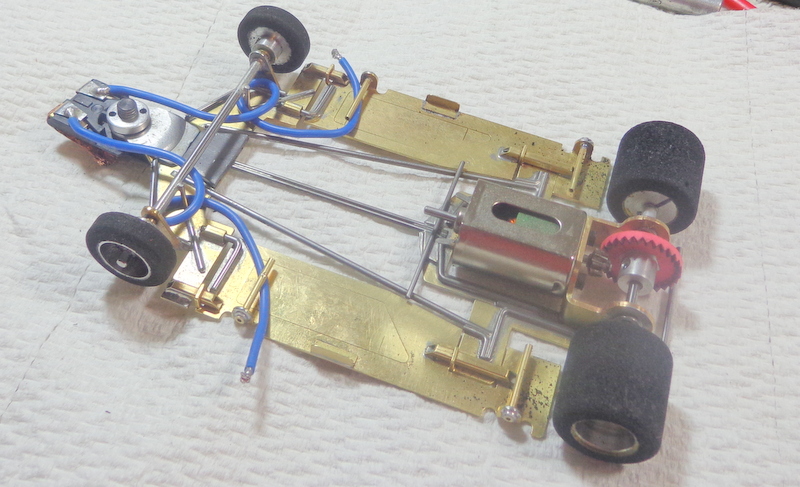

Yes, it has been a while and boyo am I rusty. Here is Rick's sorta-new Razzo chassis kit. This has been campaigning for a while but my first look at it. Rick sent along a pic of one of the more common builds and I'll follow that but also show some variations. I'm just finishing now. My initial impression is that this will be a high bite car.

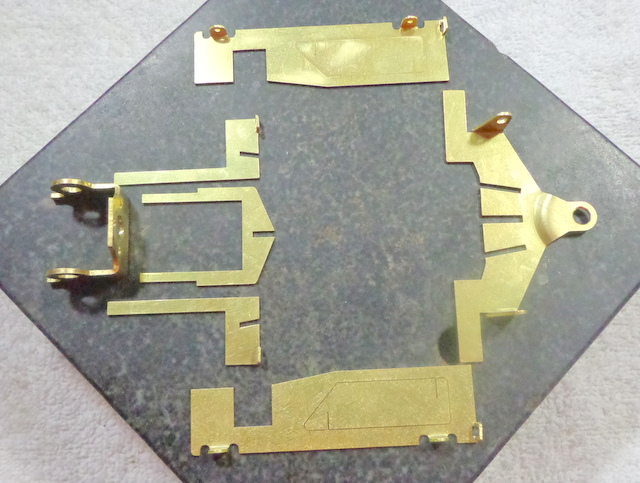

Here are the parts as supplied. 1" Z-Poid bracket, nosepiece, motor box, pan hanger wings, and pans.

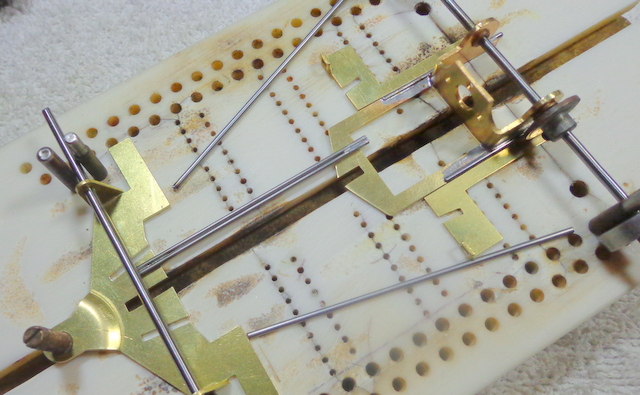

Here a couple of center rail vairiations:

Two .047" as a fixed spine.

Two .062" set-up in tubes as a tuning fork.

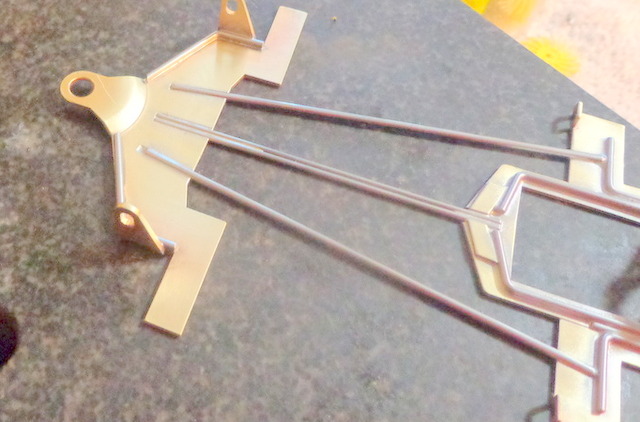

Here's another possibility. No motor box and tuning forks for rails instead as generally built by Mr. GVP.

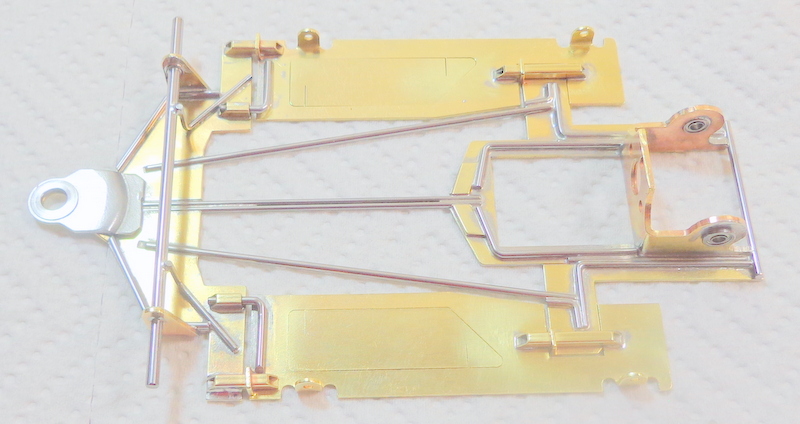

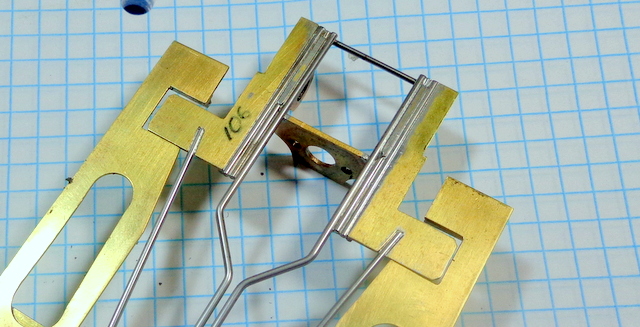

Bracket shown here getting the blueprinting treatment. Bracket face is filed until flat as always, legs squared to the face and and filed flat. Of note here is the little undercut on the bracket face. The motor box slips under this and thus, this needs to be checked to see that the box slips under easily. Carefully file until this is so.

Bracket with motor box slipped in place. Also shown here is the connector rail of .055" wire. This rail plays a major role in the assembly and assuring that the chassis is legal.

I'll do this in a few installments so I don't get too lost (like I just did on this first bit).