With a lot of "the good stuff" getting pretty scarce, it pays to look at repurposing seemingly useless parts. Of all the vintage magnet shims, I think the two-piece Champion shims ("semi-can" shims) are about as good as it gets. You can easily fit C can magnets in a D can motor and wind up with a workable hole.

Well, whenever I've been motivated to do so, there's another way to have at this. A "C" can is a tight fit inside of a D can...so tight that, depending on which C and which D cans, it can either go with some force (*an arbor press is really handy), or not go at all. It can help to take down all four sides of the C can, but doing that by sanding is painfully slow. Now that I'm part-way into the 20th Century (while the rest of the world is into the 21st Century), there's a better way...it's called machine tools. ![]()

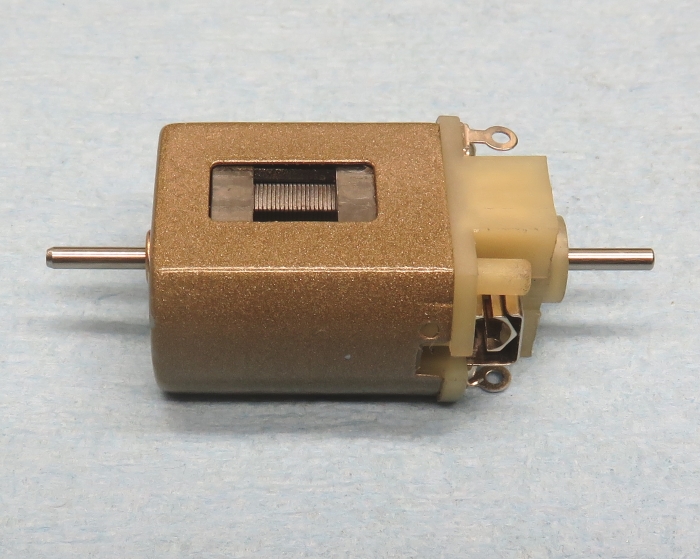

Sooo, starting with this later (I guess 1990's or so?) C can, I decided to take down a pair. One would be used as a full can-shim, the other would go back into my pile-o-stuff where it could be built into a motor, or further cut up as another shim.

It only really takes pretty much what the can needs to be flattened out, for it to be a nice "slide-fit". Of course, the arcs are a bit different, but the inner "C" can will touch the center of the outer "D can" on the two curved sides, and the top and bottom flats will match-up really nicely.

What you're left with is a can that you can install "C" sized magnets into and then slide *that* all into a D can where it can be epoxied in place. Pretty nifty!