ROUND NO.1

How to build a Shinoda Lampray, old school method

This how to is about how a thingie was originally constructed with basic tools, I have always built my cars this way. If you take your time you can build a really nice racer.

The chassis build will be a rear hinged ISO.

Lets get started.

Shinoda Lampray

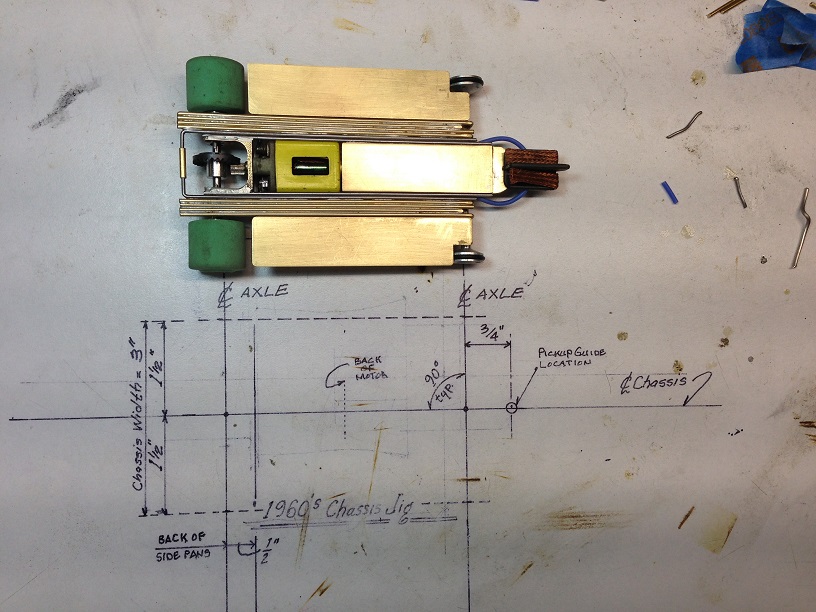

The tools shown here is what built this how to chassis.

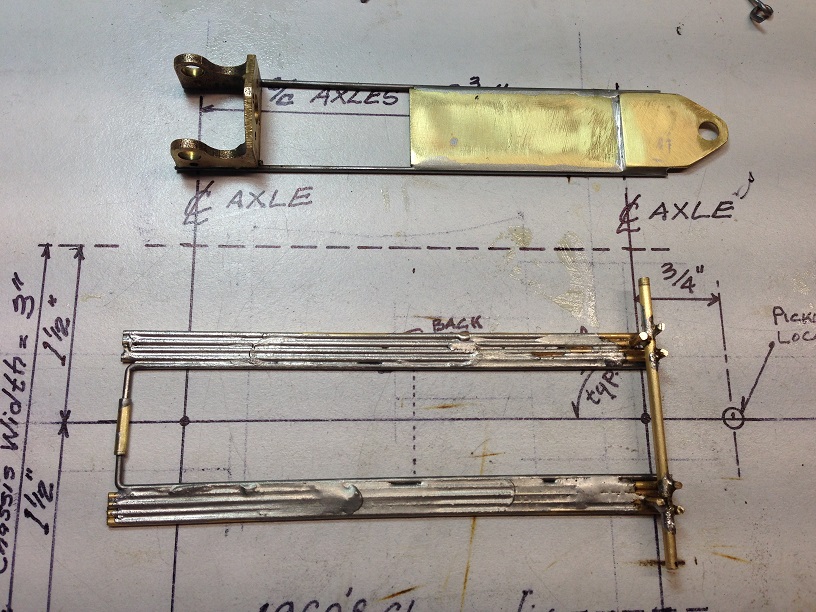

This is the only part you need to purchase.

This motor bracket will accept more than one type of 16D's

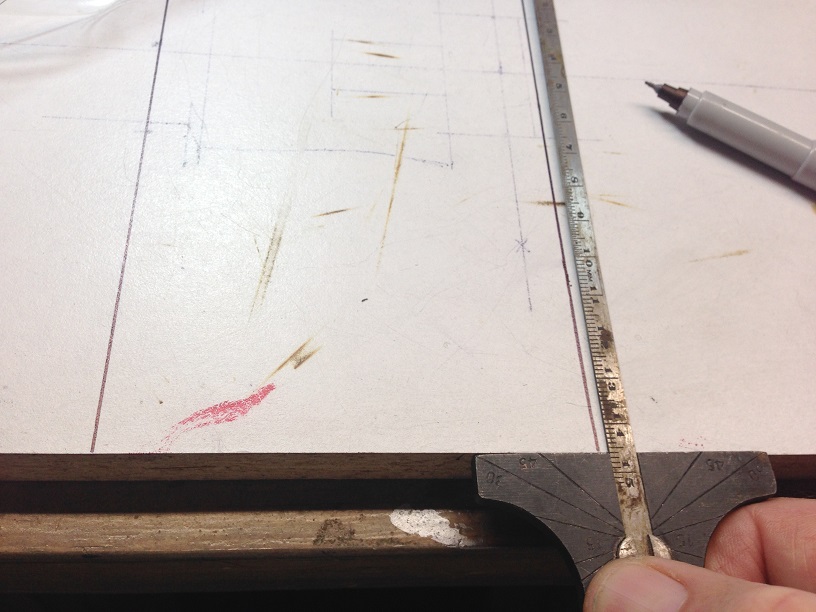

Get a flat board

Take the Lampray body and a sharpie marker and mark the wheel base.

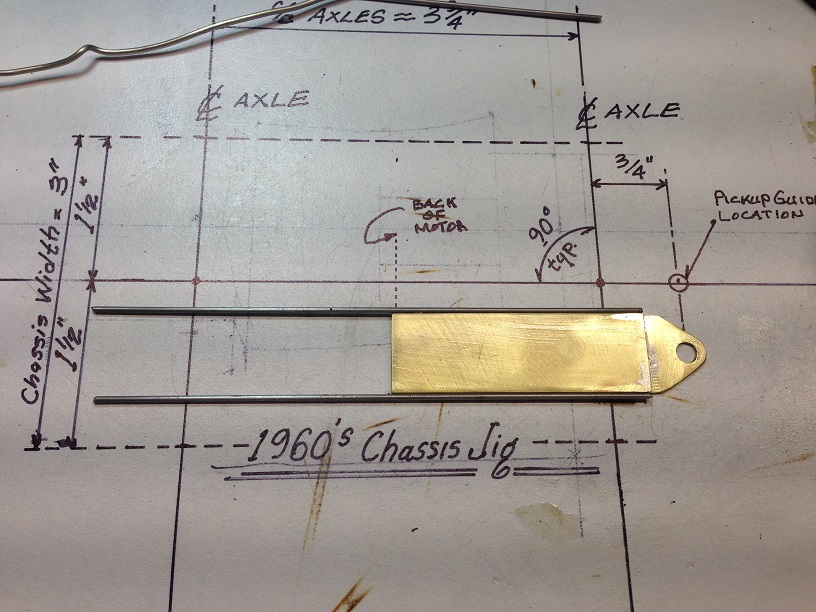

Starting to layout the chassis hands on jig, "1960's Style"

Take the square and mark the required wheel base.

Additional line work added,wheel base, chassis width, pickup guide hole location, chassis centerline.

Some additional lines will be added as we go.

Mark the hinge hole location as shown,

Use your hand drill and drill a 1\16" hole on each side.

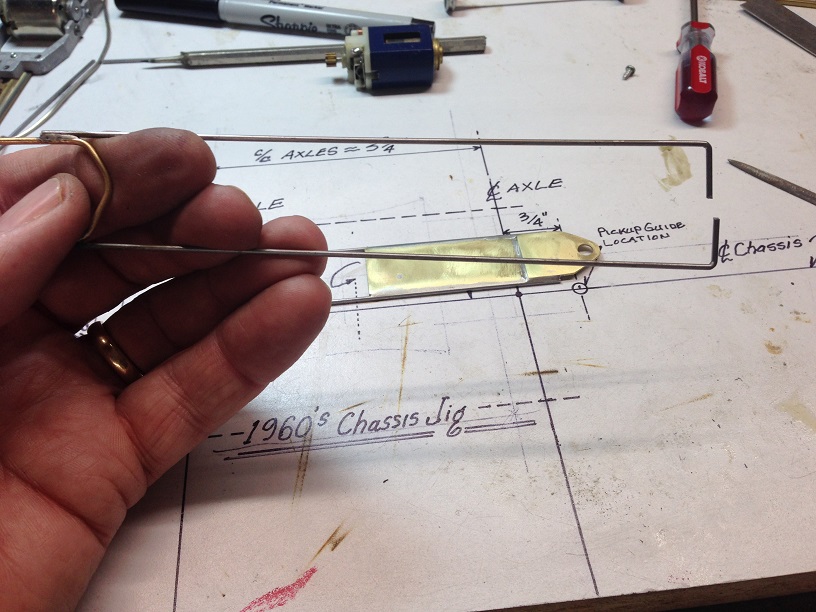

Take a piece of 3\32" piano wire and bend to fit around the motor bracket. We will cut this later.

WILL CONTINUE, stand by.

gene\zr1