I got the call to do up the big Mabuchi as a drag motor. While the short blips required for drag racing "might" lessen some of the problems with the Mabuchis, some other ones need extra special attention. Magnets are always an issue here, whether for a road car or a drag car. In this case, I was sent a donor motor (K&B) and a set of kraaa-zeee strong solid neos, super strong even by solid neo standards. So, as always, coming up with a setup is the first set of issues to tackle before even thinking about an armature. In this particular case, figuring out the magnet situation is the first step towards getting a setup done.

*These magnets are in segments, and it turns out that two segments per side is a pretty good fit for the height and inside radius of the can...with them just barely being pushed inwards by the magnet tabs. Even though the tabs will be flattened, the tips of the magnets are JUST slightly too tall, so I'm going to close-up the joint where the segments meet a bit.

*Then too, the magnets are too long for the can, so they will need shortening as well.

*Finally, the magnets are significantly thinner than the original Mabuchi magnets. As it is, the original magnets leave a large airgap and do best when shimmed way in. With the new neos, that gap is humongous. While these magnets are so guldarned strong, you might think that closing the airgap isn't really necessary. The way I see it, focusing/directing the field some...at least a little, is a good thing even with these.

Cutting these magnets is, well, awful. First of all, they can actually ignite...or at least the dust can. You need to go really slow and be ready just in case. I've had minor "flare-ups" in the past, but nothing that made me want to abandon ship...just enough to definitely make me want to pay attention. Secondly, even the dust is insanely magnetic. Getting it off the magnets is tough...but getting the dust off everything else in the neighborhood becomes a chore. Lastly, the super-slippery nickle plating on these things makes handling them even more difficult than it might be anyway.

So, after disassembling the motor and removing the stock magnets, first step is to assemble them in the can (*I use a compass to make sure I wind up with two segment-pairs that are acting as a single pair of opposed-pole magnets. That alone is really difficult because of how strong and slippery these things are. When that's all sorted, the pairs get marked as to how they get installed AND as to what edges will be trimmed to take down the height.

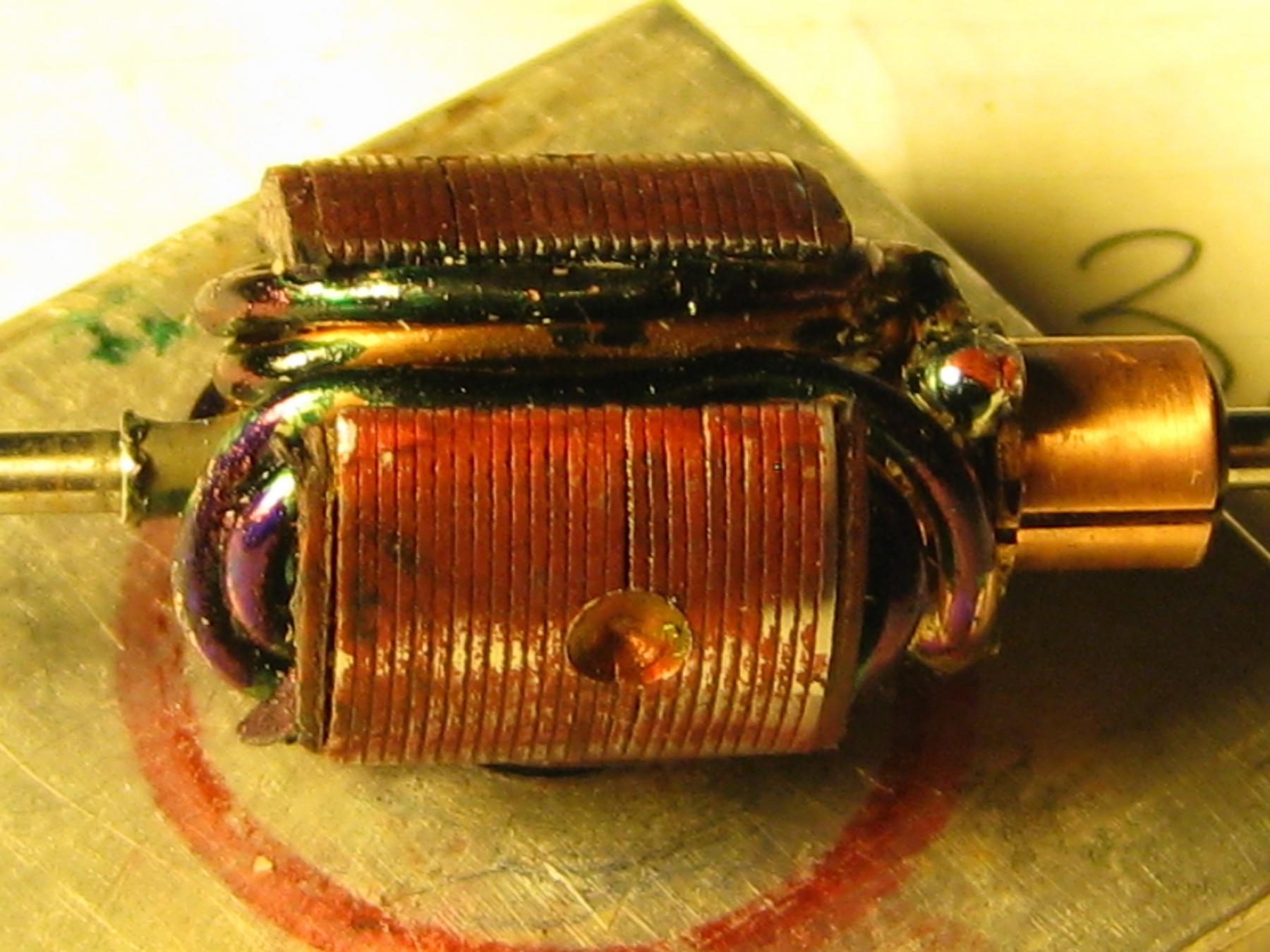

I'm going-in. If nobody hears from me for very long, send in a search and rescue team, because I might be stuck to a steel pole somewhere. ![]() I darkened the picture some so the markings can be seen a little better.

I darkened the picture some so the markings can be seen a little better.

The FT36D is still "big" with the drag crowd

#1

Posted 07 December 2017 - 10:27 AM

- Foamy, Alchemist, boxerdog and 3 others like this

#2

Posted 07 December 2017 - 10:40 AM

Hope the Proxy guy this is going to is ready for this monster

Wondered about solid segmented neos for a drag big block buchi. Fun!!!

- Tom Katsanis likes this

#3

Posted 07 December 2017 - 10:57 AM

I love the smell of R&D in the morning...

The only thing better than making stoopid stuff work is making more stoopid stuff work.

Excellent Stuff...

- Alchemist likes this

Yes, to be sure, this is it...

#4

Posted 07 December 2017 - 11:04 AM

Thanks for looking in guys. Even before cutting the "joint" where the neos will connect, a method for closing-up the gap more accurately (*if they were made to join by the factory, the joint would be an angled "pie-slice") needs to happen. I have a way figured how to do that and, however successful (*or not) that works out, I'll show the result and my method afterwards. This is going to get messy.

#5

Posted 07 December 2017 - 11:05 AM

John, will the gap between the segments have any effect on the magnetic field, ie, does the field break/weaken in this spot?

#6

Posted 07 December 2017 - 11:37 AM

John, will the gap between the segments have any effect on the magnetic field, ie, does the field break/weaken in this spot?

What I will say based on my strictly undergraduate/general knowledge of physics, and even less detailed knowledge about magnets is that all magnets generate a field that has a definite shape, and the shape of that field is due directly to the shape of the magnets themselves, and to a lesser-degree in the case of motors, the can they sit in (*which also affects the strength of that field). The edges and ends of a magnet are where the field lines begin to curve back towards the magnet itself and in the case of segmented magnets (duals, quads and up from there), you normally see the joints being very tight and precise so the magnets's field is probably more uniform, with less changes in direction from the individual segments. Variances in the shape/strength of the field can lead to losses in efficiency.

***Now these neos are not entirely an analogous situation because segmented ceramic and cobalt magnets are typically charged (zapped) once assembled, either at the factory and sold already put together, or by the motor builder after assembling the segments. These neos will not be charged after assembly, so I honestly don't know what effect how well these are assembled may have on their final strength, and/or the shape of the field they can generate as pairs. Some quick and dirty testing might be possible with iron dust on a sheet of paper, but such a crude method probably wouldn't give good enough detail to make a realistic judgement. Realistically, these kinds of assessments are best made by scientists and engineers who have studied magnetics in particular. Motors are extraordinarily complex things, even "just" magnets are awfully complicated on their own. I'm just a hobbyist.

#7

Posted 07 December 2017 - 12:11 PM

I'm very surprised there is any interest in using ancient 36's for dragging.

Is it because they have more torque compared to most 16D's?

I love revs, 26D's are my favorite in this regard, however the bottom line is torque ( with traction ) wins races.

Joe Lupo

#8

Posted 07 December 2017 - 12:20 PM

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#9

Posted 07 December 2017 - 12:36 PM

I'm very surprised there is any interest in using ancient 36's for dragging.

Is it because they have more torque compared to most 16D's?

I love revs, 26D's are my favorite in this regard, however the bottom line is torque ( with traction ) wins races.

I don't know about any drag series for modern cars that use 36Ds Joe. But, this is being created for use in the Rods N Rails drag proxy for the BIG 36D/unlimited class

Foamy showed the way to go this year and this is being done to catch Foamy

#10

Posted 07 December 2017 - 01:19 PM

I'm also anxious to see what arm is built for this motor. I feel a "beast" is about to be born!

#11

Posted 07 December 2017 - 01:28 PM

I'm also anxious to see what arm is built for this motor. I feel a "beast" is about to be born!

From what I've been told by the prospective owner it sounds like a double coat hanger

- olescratch and Racer36 like this

#12

Posted 07 December 2017 - 01:31 PM

From what I've been told by the prospective owner it sounds like a double coat hanger

Definitely hope to see the end result!

#14

Posted 07 December 2017 - 07:51 PM

![]() "Two turns of a coat hanger"

"Two turns of a coat hanger" ![]()

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#15

Posted 07 December 2017 - 09:02 PM

Hi guys. I don't really know what the motor is for. People ask me to build them, and most often I never hear about where they're going or for what purpose. If this is for chasing Foamy, then it's going to be a tall order! Anyway, I'm not 100% sure I have the magnets installed properly...but I think so. I'll post up some pictures tomorrow.

- Tom Katsanis likes this

#16

Posted 07 December 2017 - 09:55 PM

Tom

#17

Posted 07 December 2017 - 11:26 PM

.7 sec run!!!!! It would take my eyes longer than that to focus in on a car at the start line! WHEW! Turning my head from right to left that fast would result in a black out!

#18

Posted 07 December 2017 - 11:52 PM

Our next step ![]() will be to install flux capacitors

will be to install flux capacitors ![]() to hit the magical "88" mph

to hit the magical "88" mph ![]() to go back to the 60s with these beasts !!

to go back to the 60s with these beasts !! ![]()

- Geary Carrier likes this

#19

Posted 08 December 2017 - 08:53 AM

Okey dokey. Well, first I got the magnets cut both at their seam as well as their length...and that was a fidgety, dirty and worrisome mess, just as I had expected. I was going to post a picture of how I cut their seam edges, but it turned into such a chore that, once I got started I just kept going. What I did was to cut the side out of a 36D can and stick the magnets to it and then run a diamond cutting disc down the center...sort of how carpenters cut a miter in place. The thing here is that the magnet segments, when assembled so the two pairs read dead south and dead north at their seam, repel each other's edges (*although they of course attract each other at their backs the way normal arc magnets that are polarized through the arc of the same polarity do). The force required to keep them together is...well...astonishing. To make matters worse, as soon as you get close to the magnet-pair, they grab the diamond disc (backing is steel) so hard that it's all-but-impossible to hold the disc true. Calling all this an exercise in frustration would be the understatement of the century.

When I cut the length of the four segments down to around 5/8", I switched to Dremel thin cutoff discs, which solved the problem of the magnet attracting the disc, but I went through 9 discs before getting all four segments cut to length. ***As I mentioned above, you have to go slow and pay attention. The dust (*which is not good to breathe so, caution is needed there) keeps igniting, and when you feel the magnet getting warm...and then WARMER quickly, you gotta stop and let it cool down.

After all that, getting the magnet dust off the segments is really difficult and time-consuming. I used a combination of putty and tape, and you need to be sure that wherever you put them down after cleaning is completely free from anything magnetic...dust or just stuff. Otherwise, it's time to go back and start cleaning again. ***Even the paint used to paint the can has some (apparently) magnetic metallic oxides or something in it and that winds up all over the magnets. I had the can painted and the magnets installed, but after letting the paint air-dry, I put the can/magnets into the oven to bake it (less than 200F) and when I took it out, I had a perfect outline of the interior magnets stuck into the new outside paint...GAK! So then it was time to wet-sand the paint and try again, but I'm getting ahead of myself.

I was going to shim the magnets-in some, using the cutoff can sides I used to trim the segments at their joint, but I decided against that as the magnets are so strong I became worried that the finished motor would be magnet-bound...no matter how hot the arm is. I set about to installing the segments in the can and after struggling could only do one pair of diagonally opposed segments first. After the epoxy cured, I could then install the last two diagonally opposed segments which would be trapped between the first segments and the can flats (*because these segments oppose each other at their joining edges). ***Again, because these magnets are fully charged, getting them into position is really tough...like REALLY tough. This is why I'm not fully sure they are installed correctly, but it's the only way I could position them and wind up with North/South poles horizontally-opposed at the center of the can sides.

It's crazy difficult just to put an arm blank in the setup and then too to remove it because of the strength of these magnets, which is something I had to do numerous times to get the blank's shaft pushed into position...the arm that came with the motor was originally end bell drive, so I had to push the shaft to suit can-drive. I can barely spin the blank in the setup as it stands, so I'm going to go with the assumption that there's more than enough magnet here for any possible armature. It's highly likely that my power supply won't turn this motor over without tripping the circuit protection. We're in uncharted waters here.

- C. J. Bupgoo, Geary Carrier and Tom Katsanis like this

#21

Posted 08 December 2017 - 09:24 AM

Oh and BTW, I've never really checked, but there might just be some good parts...lams, shafts, magnets from RC motors (*even though those are full-round can types from what I've seen) that will work with the flat-can FT36D. For those thinking about all this drag-car craziness, that's possibly a good place to investigate.

- boxerdog and Geary Carrier like this

#22

Posted 08 December 2017 - 11:02 AM

Unfortunatly, John, my "Fireball" dragster that utilizes an R/C armature (13 turn dbl. 20) and end bell in an old Pittman train motor has brought about a ban on R/C parts at our Rods and Rails drags. ![]()

Fireball was tearing up the shutdown area, plowing through all the shutdown glue and shredding the end wall. Also VERY worrisome that it might leave the end of the track and take out the plate glass front windows of the track.

I believe the big problem is not actually the R/C parts, but the total weight of the monster.

497 grams! Running right at 1 second and 40+ mph. It just don't slow down! ![]()

- havlicek, boxerdog, Geary Carrier and 1 other like this

#23

Posted 08 December 2017 - 11:31 AM

Hi Bob...thanks for the info! Well, this motor will be legal fo'sho'!

- Pitt Man and Tom Katsanis like this

#24

Posted 08 December 2017 - 12:43 PM

If you haven't seen a pic of Bob's "car" (more like locomotive), you should. Maybe he can post one. It is an amazing piece of creativity.

#25

Posted 08 December 2017 - 01:19 PM

Just an rc arm in regular can motors should be fine. Plus there are small rc motors