CNC: Better 3D printing

#1

Posted 30 December 2017 - 10:31 AM

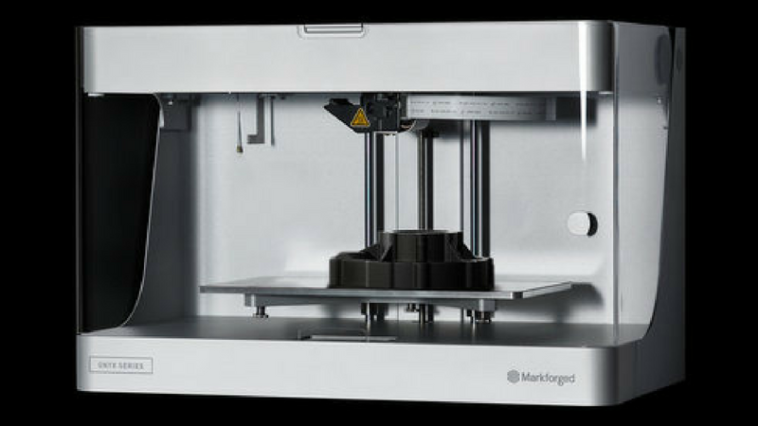

Designed to strong, high quality, uncompromised parts, Markforged 3D Printers are the worlds first 3D printers capable of printing continuous carbon fiber, Kevlar®, and fiberglass. Using a patent pending Continuous Filament Fabrication (CFF) print head alongside a Fused Filament Fabrication (FFF) print head, Markforged printers can create functional parts by combining our specially tuned nylon with continuous fiber filaments.

Dennis David

#2

Posted 30 December 2017 - 10:33 AM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#3

Posted 30 December 2017 - 10:36 AM

11/17/49-1/30/24

Requiescat in Pace

#4

Posted 30 December 2017 - 10:47 AM

Dennis David

#5

Posted 30 December 2017 - 10:49 AM

Dennis David

#6

Posted 30 December 2017 - 11:06 AM

The day I win the lottery!

EM

#7

Posted 30 December 2017 - 11:10 AM

Dennis David

#8

Posted 30 December 2017 - 12:23 PM

While hardly an automated process, I have made slot car bodies by pouring a very thin resin layer in a rubber mold and, before demolding, reinforcing the body with a layer of carbon fiber scrim* set in epoxy. The result is a light and very strong body. I use epoxy as a matrix for 3 reasons: Slower setting (hours vs minutes) allows time to place and saturate the fibre; better adhesion; cured epoxy is flexible whereas polyester tends to be brittle.

EM

* a very thin sheet of randomly oriented fibres in a binder vs the typical woven cloth-like material

#9

Posted 30 December 2017 - 12:50 PM

Dennis David

#10

Posted 30 December 2017 - 01:26 PM

Guys use Carbon Fibre to reinforce GFK bodies.

GFK?

No claim to invention - just an observation on utility of CF

EM

#11

Posted 30 December 2017 - 02:18 PM

Dennis David

#12

Posted 03 January 2018 - 12:53 PM

I’ve had my Markforged Onyx One printer for a little over a year now. So far I have no complaints, It’s the best FDM style printer I’ve ever used. My only regret is not budgeting for the Onyx Pro, but I know it can be updated later. The onyx material by itself is good for most slot car applications but in my experiences it hasn’t been rigid enough to make chassis components and it has a tendency to warp. I really need that second print head to make fiberglass reinforced parts. Until I can upgrade my Onyx One I still prefer SLA, SLS nylon printed parts, the resolution is fantastic and I’ve had good success making stuff that takes some abuse and doesn’t warp or break.

Onyx One material

- tjallen likes this

Steve Grider

#13

Posted 03 January 2018 - 02:10 PM

Dennis David

#14

Posted 03 January 2018 - 02:11 PM

Dennis David

#15

Posted 03 January 2018 - 03:43 PM

it seems like carbon fibre would work with continuous fibers but that's not really practical for small parts. Acetal Delrin is a very interesting material but tricky to print. Would need a printer made to use the material. Milling looks still to have it's advantages for the price point.

Dennis David

#16

Posted 04 January 2018 - 08:15 AM

Steve Grider

#17

Posted 04 January 2018 - 12:05 PM

Dennis David