Here's a "quickie" about how this works. Why you might be interested is easy, because modern strong magnets for these cans (I think) all are thin and produce a "hole" for larger diameter arms. If you just shim those in, the inside radius isn't ideal for smaller diameter arms...it will "work", but not well.

So, here I'm using a not very "desirable" Mura can

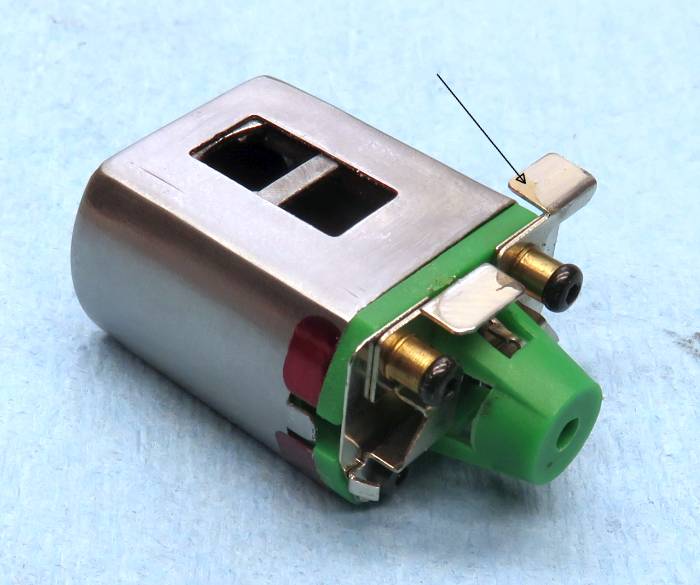

We only need the part where we want the magnet supported, and the can gets cleaned inside and out because the fit is tight...a good thing and a bad thing because, you *can* get the shim part of the way in and not be able to slide it "home". You also need to clean the D can it's going into really well for the same reason, as well as flattening the magnet tabs and even grinding them flush on the inside. Like I said, the fit is tight. With this Mura, I lost the can welds, so I wound up with a "2-piece" shim. No biggie, it's even more like the old "semi-can shims". Here's the finished shim with the magnets installed, but I also ran the seam edges on some sandpaper to make sure the shim could fully close around the magnets.

Last, before "going for it", make sure to test fit the whole mess before slathering on epoxy. It can help avoid some messy "OOPS!"

Interestingly, the same magnet and the same D can can produce measurably different results. The geeky among us probably know why, but not all C cans are the same, even when they're being cut up this way to serve as a shim. Surprisingly, the RJR can seems to be among the best. Anyway, if you like to tinker, this could be a thing. If you run vintage motors (*I guess mostly in Europe?), this sort of solution might be allowed since it is no different from period products meant for the same purpose.