I was staring at a scratchbuilder's soldering block and wishing I had one, when I realized that I could have one! 3D printing is very exact, in Tinkercad I can specify my design in thousandths of an inch, and it seems a simple enough task to create one. Also, I had noticed the Shapeways materials list included porcelain and sandstone, either of which might work for a soldering block. Another project was born!

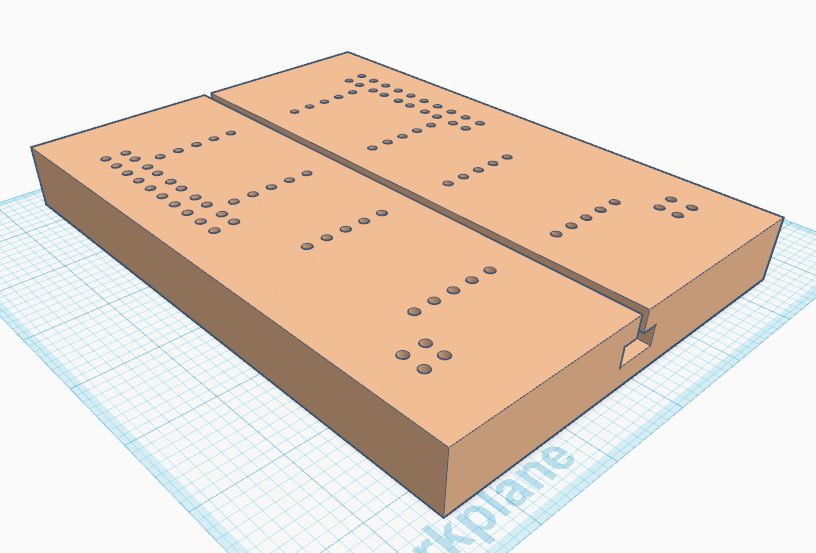

I did a quick, rough copy of the chassis jig of my dreams. Simple, with chassis lengths every half-inch from 3.5 to 5 inches, and holes for axle holder pins in 1/8 and 3/32, and a T-slot so I can use wing-nut holdfasts, or screwdowns, or whatever they are called. Voila!

So I sent the design up to Shapeways for an evaluation, and imagine my sticker-shock when the prices list for various materials appeared: PLA plastic $165, Lego-like plastic $215, acrylic $1200, stainless steel $1900!! Sandstone was $300, and my block was too big for porcelain.

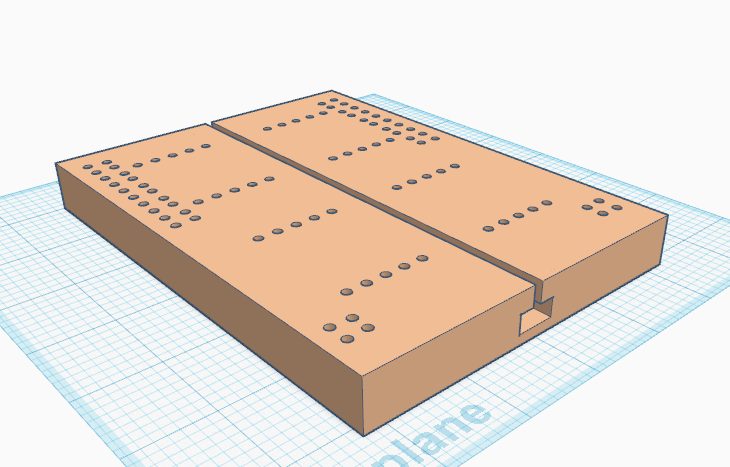

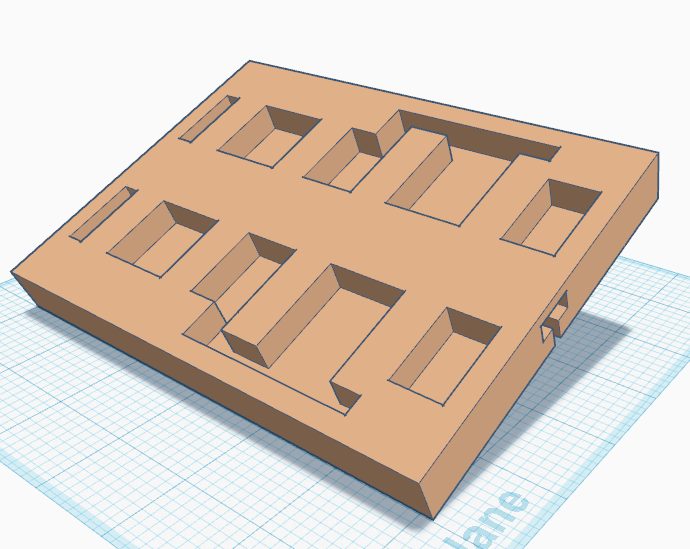

Well, that is unaffordable, and not cost-competitive with other methods. Sensible design changes might help, I hoped. I shortened and narrowed the length and width. I reduced the height. I hollowed it out, to reduce the amount of material. It cannot be made too thin, however, as it is supposed to act as a heat sink. So here is version 2, the hollowed and shortened dream block:

Alas, it seems this project is still too big for my budget! PLA plastic $88, Lego-like plastic $125, acrylic $600, stainless steel $1000. The project-desirable sandstone was $155, and porcelain $108. Still too expensive for me, and this is before cutting lots of pins, making axles and dummy wheels, and more.

So I continue to look for appropriate and affordable projects for 3D printing and slot cars. I know I said, learn by doing, trial and error. I suppose this one is a failure, although we should expect prices to be lower in the future.