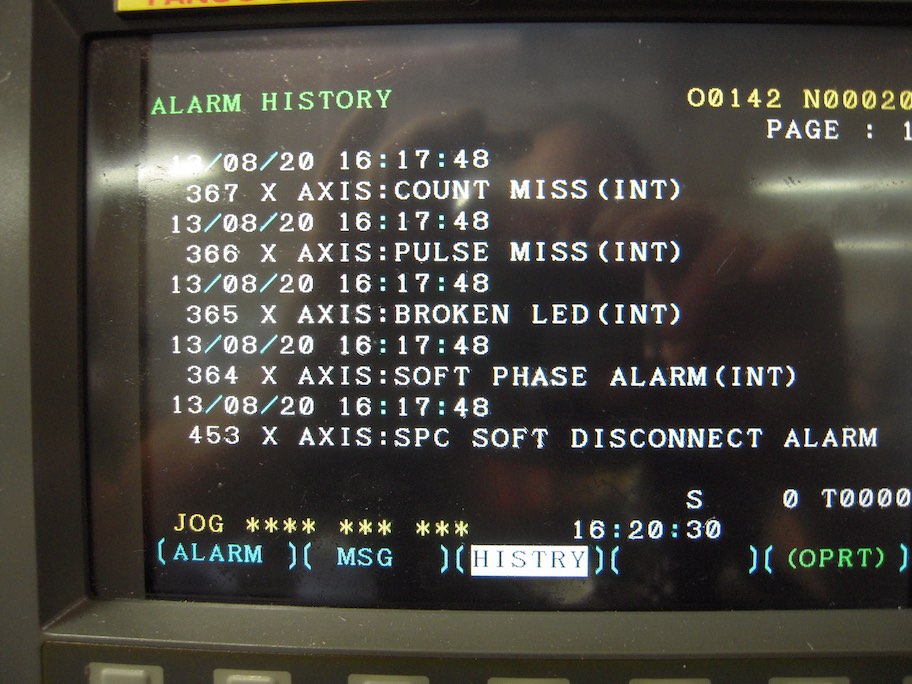

This was a while ago but it still hurts. The fix was much easier than it looked but it cost 3 days of running down the problem, getting the parts delivered, modifying the machine because the parts (not OEM but better quality and were available in 24 hours not 8 weeks!), and installation. Of course, this happened when the machine was needed the most!