Thanks for looking in guys.

May I ask, do you ever retain bronze bushings instead of tossing them - even putting better quality oilite bushings?

Hi Ernie. These motors (*as do the Chinese slot car motors) come with a sintered metal ("oilite") bushing/bearing that's perfectly fine, and I do sometimes keep them. The metal they're made from has some "yellow metal" content (copper/brass/bronze whatever), but it also has some iron content because they are magnetic...just like the slot car motor bushings. They probably went to this "formula" because iron would increase the hardness and make them longer-lasting. They are not bronze though.

Anyway, while they will wear longer than non-ferrous bushings, they can cause shaft wear if not aligned and allowed to run dry. I do use them often, but I do my best to make sure they're not slightly off, and that they're "charged" (*oiled) when I send a motor out. The way I see it, either a shaft can get worn or a bushing can...neither is good, but a motor will run just as well with any bushing as it will with a bearing. ***It's just that bearings are more forgiving of a little misalignment than bushings are. With a bushing, things have to be REALLY straight!

I've always been a fan of the FK180 motors and it seems like they are beginning to gain even more popularity because of your "motor tech".

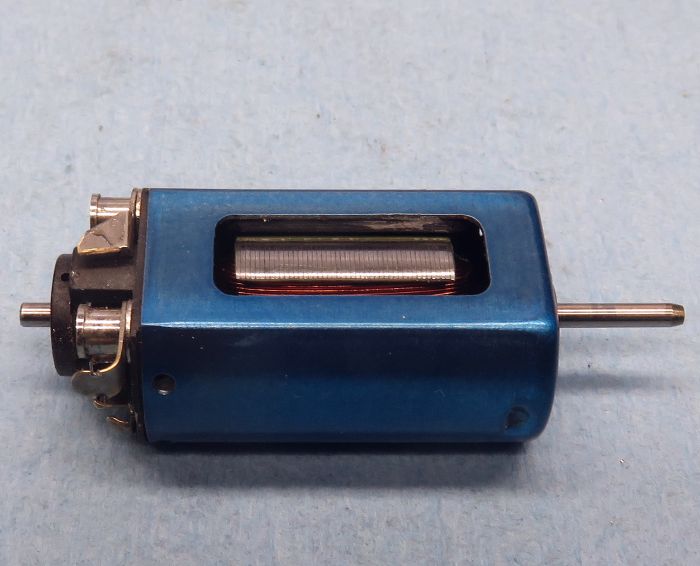

They are cool motors alright Ernie, although they can ONLY go "inline". I wouldn't know how popular they are because I've always just cut them down to "regular" (*around .750") length. If they're getting more popular now, it sure can't be because of anything I've done!

That looks very cool, and has potential to be a torque monster.

Thanks Steve. I'm pretty sure that there'll be good torque and revs here. The #29 wind version I did a little while ago sounded and "felt" impressive on my power supply. Building a chassis that works for the longer can, and then gearing it to take advantage of what the motor can do is where the real magic happens!