Hoo boy, the short answer is, "yes" of course I can.

But would it be the smart thing to do? I honestly don't know, but I have serious doubts.

Here are some reasons I can think of right off the bat:

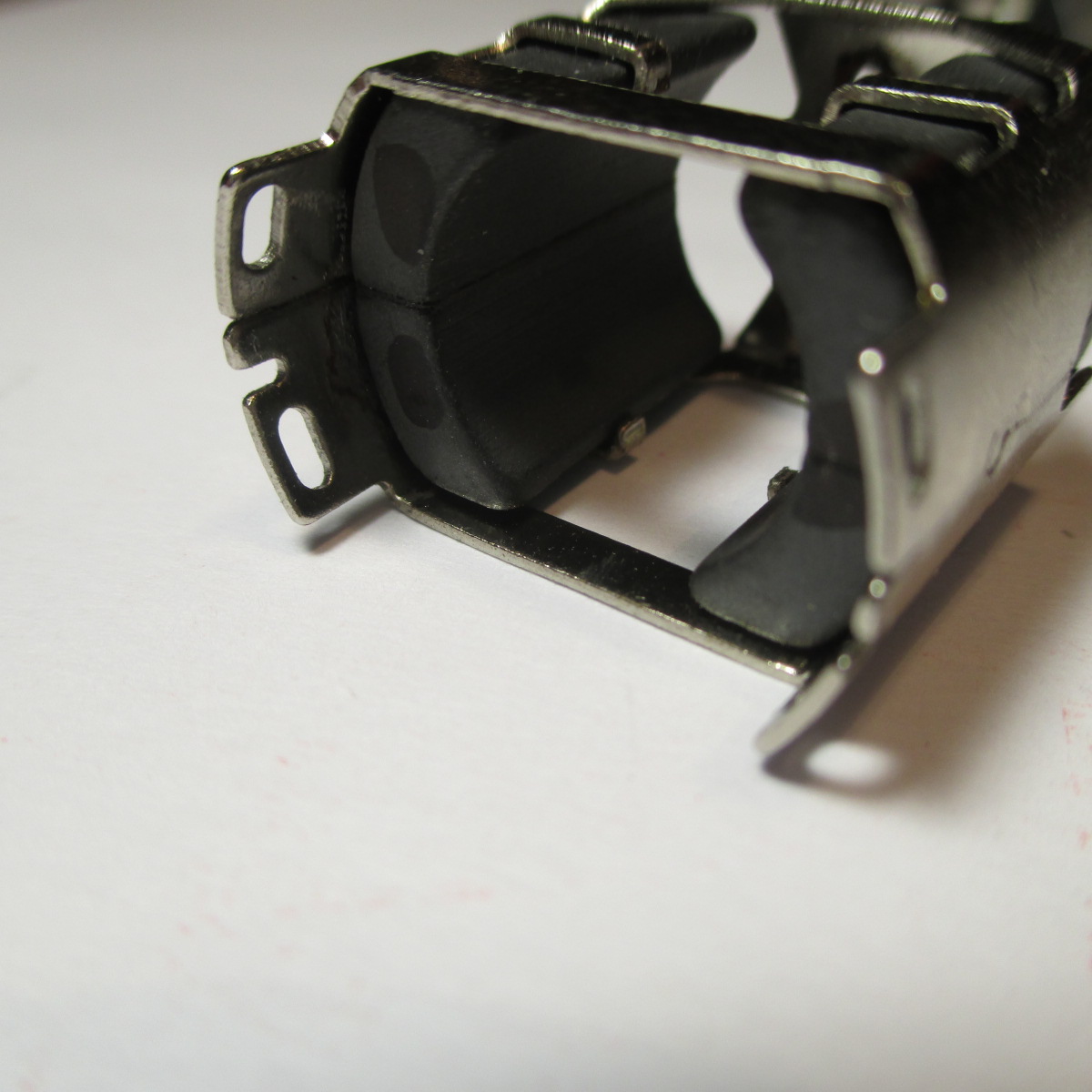

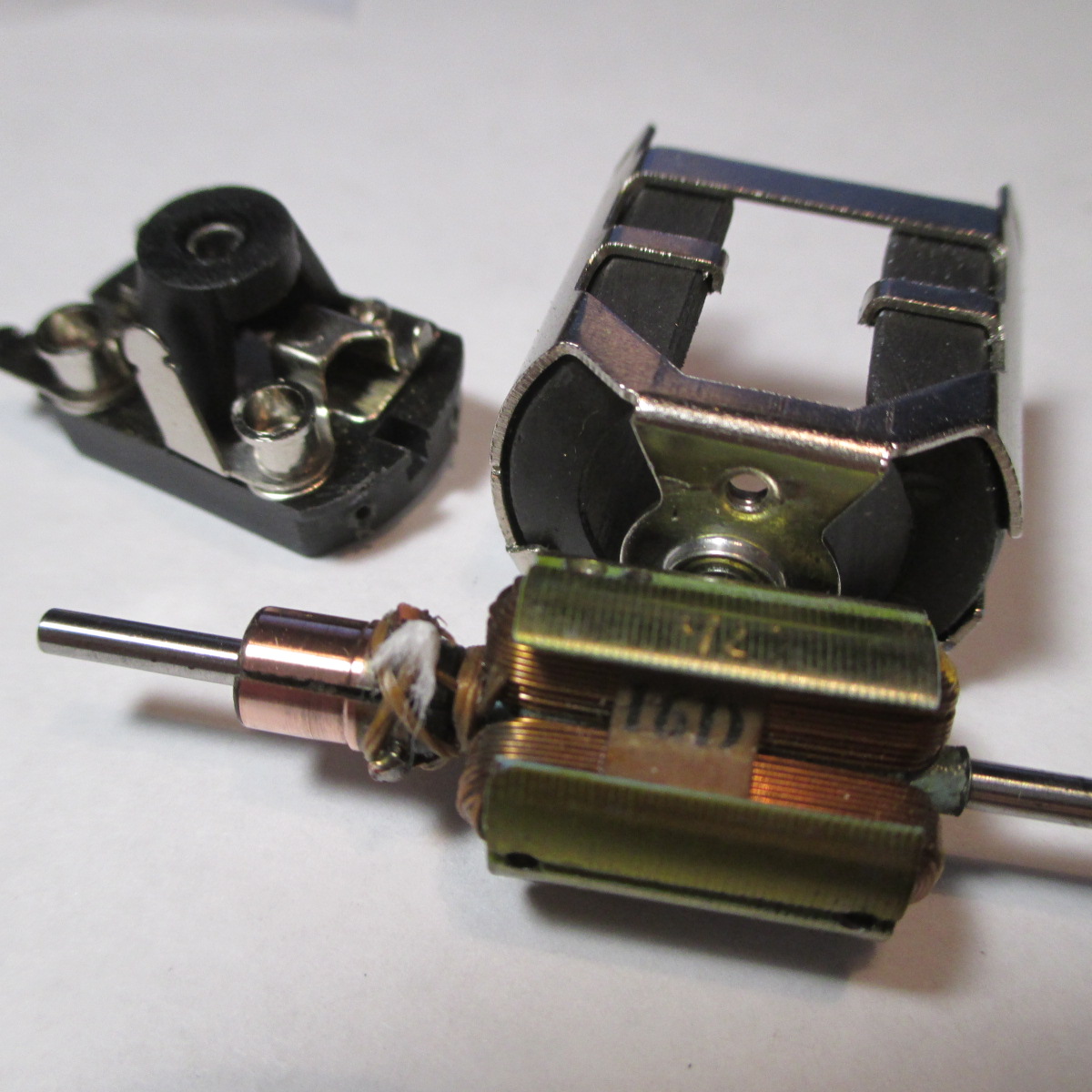

To shim the mags and re-do the BB would require completely stripping it.

At that point you are looking at a bare $6 mass produced can.

It would require straightening and possibly re-soldering the seams if it's bad.

The tabs would have to be removed and smoothed to allow shimming.

The BB hole would have to be taken down to bare metal and re-tinned.

Then re-glue the mags, possibly re-hone them to match the hole to the slug, install new BB.

The EB would probably require drilling new mounting holes to get everything re-aligned.

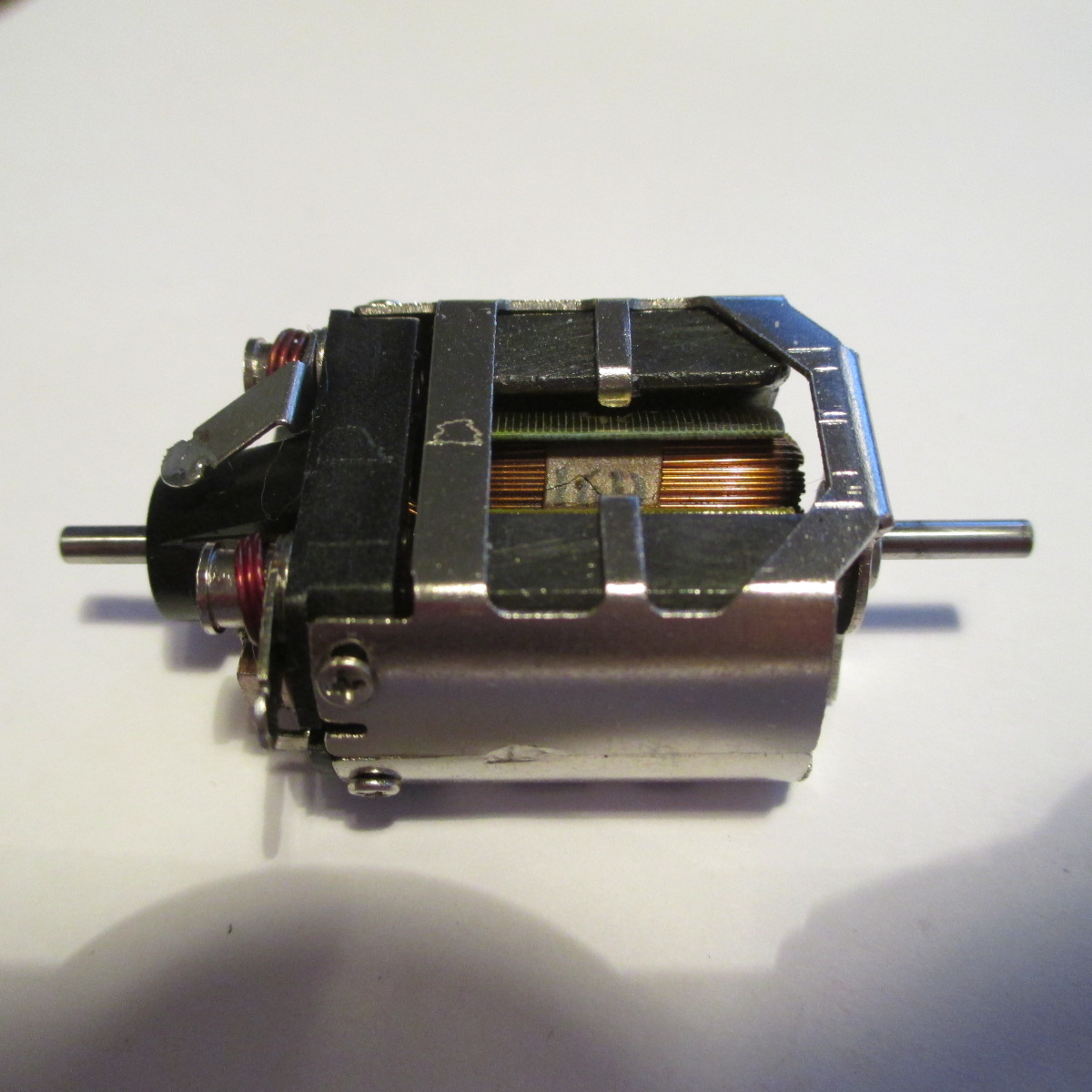

That's a lot of custom and time-consuming work to get, in the end, a bastard sized (.500 OD") arm to work.

ProSlot doesn't sell a .500 16D arm - somebody made a custom order for those for some specific application.

I wish I knew what he was thinking.

In the end, what would you have? It's up to you. That's why the very first question I asked was ""what airgaps do you want"? .513 in a .560 hole makes good sense - it's a proven combination. Alpha leads me to believe a .560 in a .580 hole also works well. But a .500 arm? IF I did shim them, I'd shoot for about .550.

If you want to pay money for that amount of work, OK. I'd need 2 pair of these:

https://e-slotcar.co...-shims-pch-012/

If they were my motors, I'd do the following:

-Bravo, shelve it, or use it as a jig motor. It's rusty and it's way out of alignment.

-Charlie, I'd order a new PS 706B .540 OD with 45 deg. timing and leave the .568 hole as is.

-Delta, I'd order a PS 706B .560 OD with 42 deg. timing and hone the hole to .580, same as Alpha.

![]()