I haven't posted much this year because I haven't really done much of anything new and posting pictures of stuff I've reported on before doesn't seem to make that much sense. But...........part of this build is new, at least to me.

This is a pretty standard "GVP" style tuning fork chassis. Components used were an R-Geo "Razzo" nosepiece and R-Geo "Z-poid" 1" bracket.

Nosepiece is .040", bracket is .050, pans are .032.

Fork rails are .062, frame rails are .055

Hinges are .062 wire in 3/32" sq. tubing.

Front stops are .055 wire in 3/32" sq tubing.

Weight as shown is 53.5 gr. which is a good starting point for a NorCal Can Am.

Here's the "new to me" part. I was discussing building a tuning fork frame for a very good Motown Racer and he suggested this addition. I'm sure this has been done by others but I haven't seen any testing or reports on the concept so here I go............

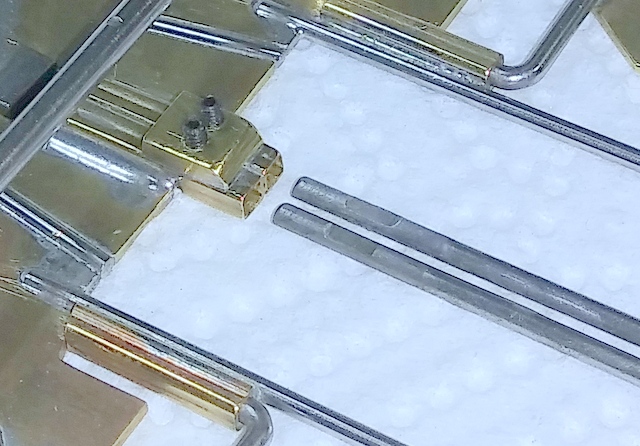

The fork tubes have a tiny block of 1/16" brass on top that is drilled and tapped as shown here for #0-80 set screws. The usage is obvious. With the screws down tight, the forks are locked and don't rotate in the tubes. Back them off a turn, and they are free. The pic shows a couple of the #0-80 set screws on the right with a couple of std. #4-40 on the left for scale.

In messing with it, the difference in flex is very noticeable. What it will do on the track remains to be seen but I'm guessing the difference will be subtle. I'm pretty excited to test this. Enough so that I don't think I'll even bother to clean up the solder joints before I put it on the track. Hope to get it on track tomorrow or the next day.