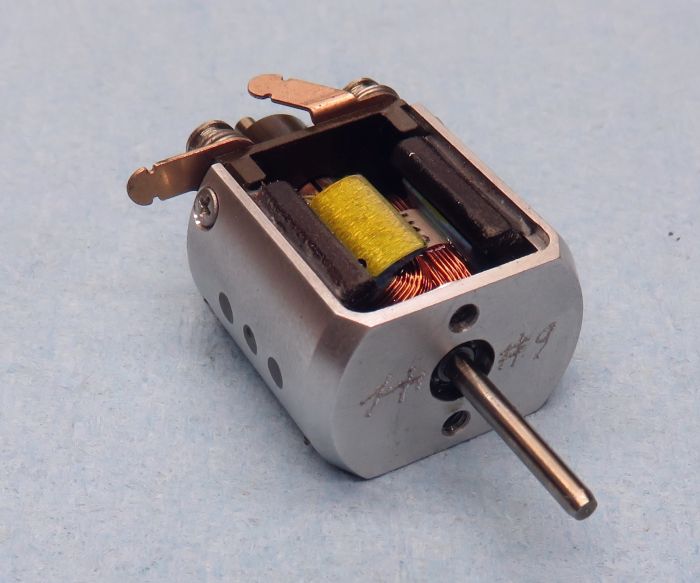

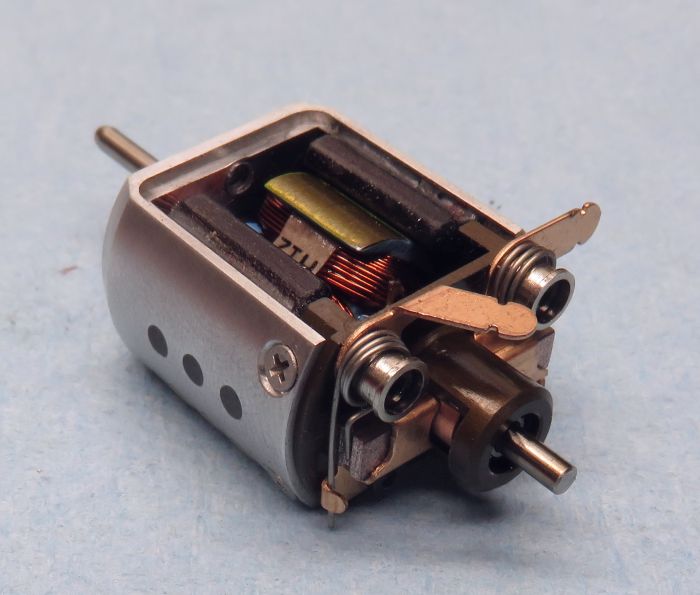

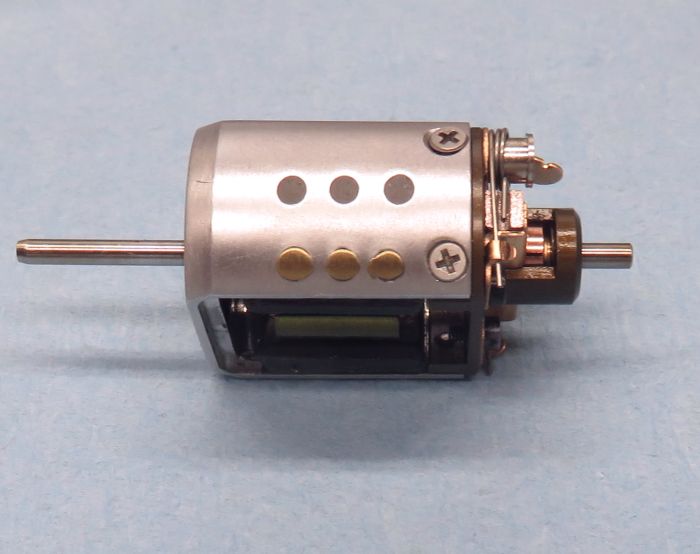

I did a second one of these aluminum cans, and changed things up a little. For one, I used poly neos here and kept the airgap tight. I also used smaller holes/countersinks to make the "through-the-can-sides" epoxy keys for the magnets. I also removed the screw heads from the brass screws used to provide a solder point. For the arm, I wound a 50/29. The motor spins up like an absolute champ, very fast and smooth indeed! For sure, making a can out of aluminum has it's challenges, but the stuff definitely works well and even with the challenges, makes for a very light can.

Aluminum billet strap (#9)

#1

Posted 09 September 2018 - 03:03 PM

- slotbaker, proptop, Jencar17 and 2 others like this

#2

Posted 09 September 2018 - 04:44 PM

There is something I have to vent about and it has **NOTHING** to do with John's fantastic work: the word BILLET.

Somewhere, sometime ago, someone who had no idea how to describe a fully-machined piece of metal that wasn't formed by any sort of casting or forging used the word billet. Now, billet is a very specific word used for the piece of metal, at the mill, that has not been rolled, forged, drawn or any other sort of millwork performed on it. It is a very raw piece of metal that often has defects that need to be removed before the required millwork is performed. It is NOT desirable metal from a finished product point-of-view.

Perhaps I shouldn't care, and it's way too late to make a difference, but it makes me cringe every time I see the word used as a favorable noun. The hot rods guys (the manufacturer's marketing departments, specifically) throw the word BILLET around without knowing the true meaning, source and history of the word. This "educates" the readers that "billet" is something special and desirable. IT IS NOT.

If the marketing guys want to say that a valve cover or a crankshaft is NOT cast or forged then they could say, "machined from wrought metal" or use "wrought" in the description.

Sorry for the little rant but it bugs me.

Thanks for your patience....

- brnursebmt likes this

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#3

Posted 09 September 2018 - 05:11 PM

john you are scaring me ![]()

- havlicek likes this

Paul Wolcott

#4

Posted 09 September 2018 - 07:06 PM

Hi Phil,

Honestly, I always thought a "billet" was simply a lump of metal either cast or extruded, that could be further formed by machining or whatever. If that's the case, then the term applies. If that's not the case then some goofy slot car person who started using the word needs to be reprimanded ASAP! ![]()

#5

Posted 09 September 2018 - 07:13 PM

I can see this thread going sideways PDQ, and that's fine with me...BUT:

"A billet is a length of metal that has a round or square cross-section, with an area less than 36 in2 (230 cm2). Billets are created directly via continuous casting or extrusion or indirectly via hot rolling an ingot or bloom. Billets are further processed via profile rolling and drawing."

https://en.wikipedia...asting_products

So while the term may or may not be precisely correct, it does seem to apply to the things these cans are made from...although not what they wind up as, or something like that.

#6

Posted 09 September 2018 - 10:14 PM

Continuous castings or extrusions aren't usually the bestest stuff. Yeah... you can buy extruded metals (Aluminum and Magnesium ((which is the only way it comes in a bar form)) are two examples) directly from metal suppliers but their properties are poor compared to cold worked, cold rolled or forged metals. The material you made your can from is likely to have been cold worked.

Note the definition says *nothing* about the material in a *finished* form. Note that it says billets are processed further.... llike into cold drawn bars and rods, cold rolled plate and sheet and forgings... hence, billets are not "shop ready" materials... not unless finding inclusions, folds, and voids is somethiing "you" think is superior metallurgy...

but then, again, maybe someone would think that a crankshaft made from a steel extrusion is something high-grade.

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#7

Posted 10 September 2018 - 04:13 AM

Well, absolutely correct or not, the term gets tossed about even more in the auto industry (*especially with wheels) than in slots, and seems even less applicable. Anywho...the word is a widely used term in slots for describing a can machined from a lump of metal, so I'm not gonna start using a new one. No one would know what they heck I mean! ![]()

#8

Posted 10 September 2018 - 09:44 AM

Hey...someone somewhere came up with "Unobtanium"...now it's a widely used term too...so why not come up with your own name for it...?

You could list it on ebay...

A super "Rare" specimen...

"There I was, just sitting there minding my own business, watching TV, when this strange sort of metal meteorite came crashing thru my roof! So I did what it is I do...I made a motor out of it..."

That motor could be worth millions! ![]()

- MarcusPHagen and havlicek like this

Tom Hemmes

Insert witty phrase here...

#9

Posted 10 September 2018 - 09:49 AM

Well, absolutely correct or not, the term gets tossed about even more in the auto industry (*especially with wheels) than in slots, and seems even less applicable. Anywho...the word is a widely used term in slots for describing a can machined from a lump of metal, so I'm not gonna start using a new one. No one would know what they heck I mean!

This is true. Sorry for my rant...

By the way...getting back to the subject...how quickly does the motor heat up? I suppose with the poly mags the heat doesn't transfer to the aluminum very quickly. It's time to put it on the track and let it loose.

Click HERE to contact Sonic Products. The messenger feature on my Slotblog account has been disabled.

#10

Posted 10 September 2018 - 07:23 PM

This is true. Sorry for my rant...

By the way...getting back to the subject...how quickly does the motor heat up? I suppose with the poly mags the heat doesn't transfer to the aluminum very quickly. It's time to put it on the track and let it loose.

The motor doesn't seem to heat up much at all. Then again, I never run them for very long because...well...they're supposed to be new when I send them out ![]() It seemed very fast and smooth, with nothing unusual at all going on that I could tell.

It seemed very fast and smooth, with nothing unusual at all going on that I could tell.

- olescratch likes this

#11

Posted 11 September 2018 - 07:51 AM

This thing looks great! Your creations never let us down.

Would it be possible to incorporate ferrous shims?. They are needed for efficiency reasons.

- havlicek likes this

#12

Posted 11 September 2018 - 08:07 AM

John=

Great job!

The Phoenix sealed can motor might be a source for you of strong Neo magnets.

Cheers

- havlicek likes this

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#13

Posted 11 September 2018 - 12:24 PM

John,

This thing looks great! Your creations never let us down.

Would it be possible to incorporate ferrous shims?. They are needed for efficiency reasons.

Hi Dave and thanks. These things fall into my "experimental" category, but it doesn't at least seem as though the shims are necessary at all. On these two aluminum can motors, I did decrease the inside diameter to close-up the airgap some, with a step at the outside to fit the end bell. Since I use JB Weld to install the magnets, which is magnetic, maybe that has helped a little?

John=

Great job!

The Phoenix sealed can motor might be a source for you of strong Neo magnets.

Cheers

Hi Bill, and thanks also! Pablo sent me a set of those that I loaded into one of these motors not long ago. They seem to be precisely the same as the "Emovendo" and other similar "solid" neos out there. Very strong magnets indeed, but you need to be really careful about exposing them to heat, maybe even more so than the regular "poly" neos.