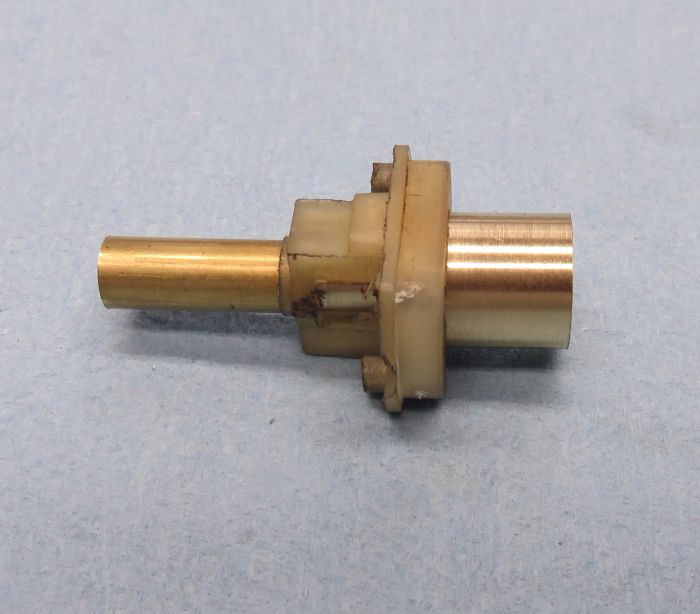

I don't have all that much use for one of these, but decided to have a go at making one just because. This was the simplest design I could figure, and it works perfectly. It's nice to be able to just whip up things to make a job easier!

Doo-dads, doohickies, and gizmos

#1

Posted 02 October 2018 - 11:35 AM

- Tex, Geary Carrier and Slot-Racer like this

#3

Posted 02 October 2018 - 12:19 PM

So this is what bullet proofing is all about...

- havlicek likes this

Yes, to be sure, this is it...

#4

Posted 02 October 2018 - 01:59 PM

So this is what bullet proofing is all about...

![]() I see what you did there!

I see what you did there!

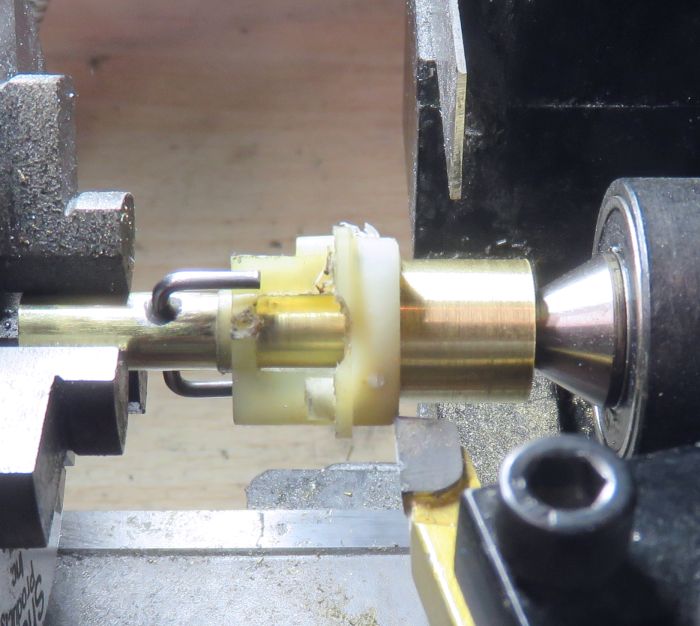

I was actually surprised this thing worked as well as it does. I thought the end bell would just stand still when the cutter contacted it since there's only the friction/pressure of the live center against the fatter piece keeping it rotating. I was going to cross-drill the smaller diameter piece and install a piece of piano wire with one or two bends that would hang over the sides of the tower. I decided to try it as-is, and it worked...go figure. If that doesn't work in the future, I can always add the piece.

- Geary Carrier likes this

#6

Posted 02 October 2018 - 07:49 PM

I made one of these mandrels in the early '70s. I mounted the shaft to a 1/16" plate. I screw an endbell to the plate with a 2-56 screw to prevent it from rotating as it was being cut. I made mine to fit Mura C-can endbells on Champion cans. Larry Shephard made a 2-piece mandrel to cutdown Mura endbells to fit 'FK' cans.

I intend to live forever! So far, so good.

#7

Posted 03 October 2018 - 06:00 AM

I made one of these mandrels in the early '70s. I mounted the shaft to a 1/16" plate. I screw an endbell to the plate with a 2-56 screw to prevent it from rotating as it was being cut. I made mine to fit Mura C-can endbells on Champion cans. Larry Shephard made a 2-piece mandrel to cutdown Mura endbells to fit 'FK' cans.

I've seen probably three or four different jigs/fixtures people have done (*and there's probably many more) for turning-down end bells. Once mounted, it seems as though the end bell could be turned to fit any can down to an "fk" or maybe even smaller. I'm not quite envisioning what yours was from the description, but when cans started getting smaller, it was a natural to turn down end bells to fit.

*I got a strange (*but really quite nice!) can and matching turned-down Mura end bell not long ago from Russell Sheldon down in SA that's a good example of all this. I will do something with the setup at some time, because it's too neat to just let it sit around.

#8

Posted 03 October 2018 - 10:55 AM

I can see where this tool would come in handy especially when doing fk conversions, did you make any extras?

- havlicek likes this

#9

Posted 03 October 2018 - 11:18 AM

I can see where this tool would come in handy especially when doing fk conversions, did you make any extras?

Hi John,

I only made the one tool, because I figure that in order to use it, you'd have to have a lathe, and if you have a lathe, you could just make one. This is significantly simpler than other designs I've seen though, and I kept that in mind when I made it. Some I've seen had a couple of drilled and tapped set screws for holding everything together, which is accomplished here by just using the live center.

So basically, there's one piece turned to fit the end bell bushing hole (6mm), and that's the end that goes into the lathe chuck. Then there's a second larger piece that fits the inside hole of the end bell nice and snug that has been bored to fit the first 6mm piece. The larger piece also has a chamfered hole for the live center to engage. You just install the larger piece from the inside, then slip the smaller piece through the outside and into the larger piece, and then chuck the whole mess in the lathe...running the live center into place to support the end.

***There's also the piano wire cross piece, but that's no big thing and might not even be necessary (?) depending on how well the other two pieces fit each other and the end bell.

- C. J. Bupgoo likes this

#10

Posted 03 October 2018 - 03:43 PM

Nifty piece of work there... but I'm not clear: what are you trying to do with the tool? Ream out the inside of an endbell and make sure there's a 6mm hole for the bearing? And then cut some plastic off for clearance on the outside?

![]()

![]()

Alleged amateur racer.

Mostly just play with lots of cars.

Able to maintain slot cars with a single bound.

Faster than a speeding Womp.

More powerful than a 36D.

#11

Posted 04 October 2018 - 03:33 PM

Nifty piece of work there... but I'm not clear: what are you trying to do with the tool? Ream out the inside of an endbell and make sure there's a 6mm hole for the bearing? And then cut some plastic off for clearance on the outside?

This fixture is for turning down C-can (*in this case Mura) end bells to fit smaller cans, such as the "fk" size. This was done often when motors first started getting smaller with the "peanut" motors, but there are still reasons to do it sometimes today.