...so far anyway. By this time, I've already done the head-scratching for many of the things I want/like to do to various motors. That shortens the time it takes to build them, although I still figure new things to do from time to time, and that lengthens the time some more. ![]() Still, I figure I'm "saving time" by being comfortable with a lot of the steps. I figure I'm about eight hours into this 26D...at least so far.

Still, I figure I'm "saving time" by being comfortable with a lot of the steps. I figure I'm about eight hours into this 26D...at least so far.

The can got "the treatment"TM , and considering the thinner metal of the Mabuchis, you gotta be more careful and go a little slower. The can also got a bearing adapter and new bearing, but I also made the adapter's inner flange large enough to include threaded holes (2-56) for solid bracket mounting.

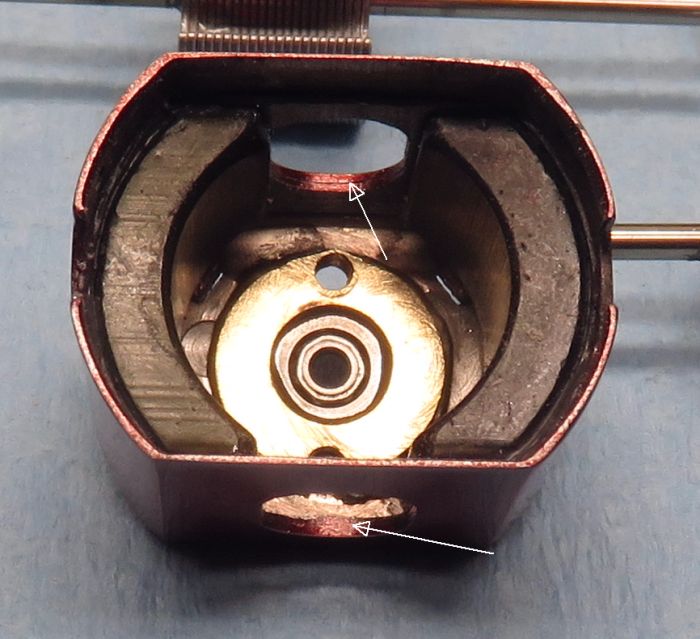

I tore apart a Mabuchi FC280 for it's magnets. The stock ones measure somewhere in the mid-700 range, Arcos measure in the low-to-mid 900 range, these measure around 1050 or so...BUT...that's mounted in the can and after shortening them, a really messy and time-consuming PITA. Oh and, I wanted to keep the stock FC280 airgap which is about 25 thousandths over (*or around 12 thousandths per side). The FC280 magnets are close to the same thickness as Arcos and both need to be shimmed for the Mabuchi 26D can. Sooo...I flattened and thinned the FC280 can way down so it would fit into the 26D can, cut away what I didn't need and used it to shim the magnets inside the 26D can.

While I was at it, I cut out the inner can shim holes to match the existing 26D can's oval holes by roughing them on the mill and then finishing them off with the Proxxon and a skinny bur, another slow process (*see arrows)

On the end bell, this one came with 36D hoods (*it's always a treat to see what hardware comes bundled with the Motors Etc stuff ![]() ), which isnt a bad thing, since the larger surface area might help dissipate heat. This means modifying them to fit the smaller 26D end bell. After getting them to work, they got soldered to the brush tubes/heat sinks. I could then make up an adapter for an end bell bearing, which got epoxied into the adapter which itself was a "press fit"...nice and snug.

), which isnt a bad thing, since the larger surface area might help dissipate heat. This means modifying them to fit the smaller 26D end bell. After getting them to work, they got soldered to the brush tubes/heat sinks. I could then make up an adapter for an end bell bearing, which got epoxied into the adapter which itself was a "press fit"...nice and snug.

When I was pretty sure I had done everything I was going to, I painted the can "Anodized Red", stripped and re-shafted the FC280 arm. So, with more to go, I'm about 8 hours in at this point. What?...you didn't think this stuff was fast and easy did you?