How solder actually works

#1

Posted 26 November 2018 - 11:34 AM

What the flux: How does solder work anyway?

Cheers,

- Geary Carrier and Slot-Racer like this

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#2

Posted 26 November 2018 - 12:21 PM

Intermetallics are necessary to a good solder joint, but like so many things, too much of a good thing can be a bad thing. Intermetallics tend to be brittle, so if the intermetallic layer is too thick, the joint can be mechanically weak. There can also be voids within the intermetallic layer that add to mechanical instability.

How does one determine this?

IOW, how do you know when you have too thick of an intermetallic joint?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#3

Posted 26 November 2018 - 01:08 PM

I think that in the video, the presenter is trying to convey that a tight fit between the two parts to be joined is very important.

Lead solder, or any solder for that matter, has very little tensile strength on its own. The chemical bond formed when the solder is melted creates the strength. Too much solder between the two parts makes a weaker joint.

- Cheater and Slot-Racer like this

#4

Posted 26 November 2018 - 01:43 PM

Mike:

There's really no non-destructive way of finding out the thickness of intermetallics in a solder joint. Generally this is determined in a laboratory where samples of the items to be soldered are prepared and then those samples are cut, mounted, and polished, and then inspected under extreme magnification. This is generally done to develop a process plan for the items being manufactured.

A good example of this is in the high-reliability missile electronics I was involved with. First we had to tin a gold-plated electrical contact, wick off that solder, tin it again, and then wick that solder off. Only then could we make the final solder joint. This was to remove virtually all of the gold plating which, if left on, would produce a very brittle gold/tin intermetallic layer and lead to cracked joints in this extreme vibration environment. This process was determined by very extensive and expensive laboratory testing, not something that could be done at home.

- Cheater and Slot-Racer like this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#5

Posted 26 November 2018 - 01:59 PM

#6

Posted 26 November 2018 - 02:49 PM

Solder is interesting creature. When I was little I always though it was neat how when it falls on other objects it just turns into a ball or splats.

#7

Posted 26 November 2018 - 04:52 PM

The problem is that destructive testing is not viable for us hobbyists...

I can assure you I did a lot of destructive testing during my years as an active slot racer! LOL!

I didn't really mean to be doing destructive testing, of course...

- Half Fast and boxerdog like this

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#9

Posted 26 November 2018 - 06:07 PM

There's really no non-destructive way of finding out the thickness of intermetallics in a solder joint. Generally this is determined in a laboratory where samples of the items to be soldered are prepared and then those samples are cut, mounted, and polished, and then inspected under extreme magnification. This is generally done to develop a process plan for the items being manufactured.

A good example of this is in the high-reliability missile electronics I was involved with. First we had to tin a gold-plated electrical contact, wick off that solder, tin it again, and then wick that solder off. Only then could we make the final solder joint. This was to remove virtually all of the gold plating which, if left on, would produce a very brittle gold/tin intermetallic layer and lead to cracked joints in this extreme vibration environment. This process was determined by very extensive and expensive laboratory testing, not something that could be done at home.

Thanks for the reply, Jay.

It’s black magic.

That guy in the link must be used to working on something very tricky.

If assembling slot car chassis was that precise, half of them would be falling apart in practice. LOL.

- Pablo, tonyp and boxerdog like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#10

Posted 26 November 2018 - 08:02 PM

#11

Posted 26 November 2018 - 08:49 PM

I can assure you I did a lot of destructive testing during my years as an active slot racer! LOL!

I didn't really mean to be doing destructive testing, of course...

I think I did a pretty good job of destructive testing on one of your cars at Flashbacks one time... And nothing broke!

I guess your soldering iron works OK!

Rotor

- Cheater likes this

"Kinky Kar"

#12

Posted 26 November 2018 - 09:24 PM

But I learned that the adjoining metals need to melt the solder, not the tip of the iron. For a long time I melted solder into my work instead of getting the work hot enough to melt the solder and pull it in (intermetallics).

I can make a pretty sound joint now. Still not pretty, but it stays together.

Matt Bishop

#13

Posted 26 November 2018 - 11:54 PM

i never have a bad solder joint because i use a torch & use stay clean flux. that's it.

First Place Loser in the JK Products

International D3 Builders Competition

#14

Posted 27 November 2018 - 02:46 AM

A good joint comes from experience.

A bad joint comes from a lack of experience.

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

#15

Posted 27 November 2018 - 08:00 AM

Did yaz all scroll down and see the pic of the young lady and the way she's holding onto the soldering iron?

(And by the looks of it, she's gonna solder the motherboard battery!?)

- Half Fast likes this

Tom Hemmes

Insert witty phrase here...

#16

Posted 27 November 2018 - 08:16 AM

Soldering isn't hard to do, only hard to master. I can't come near the pretty work most of you guys do.

But I learned that the adjoining metals need to melt the solder, not the tip of the iron. For a long time I melted solder into my work instead of getting the work hot enough to melt the solder and pull it in (intermetallics).

I can make a pretty sound joint now. Still not pretty, but it stays together.

In typical USRA type wing or Flexi racing, you have to apply solder from the tip to the fluxed area to be soldered. You have no other choice, as you need to hold the motor with your left hand.

Same applies to Retro chassis building. 75% of the time you need your left hand to hold something in place.

The big advantage of having solder on the tip vs. heating the area and feeding in the solder is superior heat transfer.

Both new and semi experienced racers will be surprised when they see me taking a motor out of an older style flexi, where it is soldered on top, by adding solder to the joints.

- tonyp, NSwanberg and MattD like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#17

Posted 27 November 2018 - 08:22 AM

#18

Posted 27 November 2018 - 10:01 AM

I try to put together brass that looks as nice as what you guys do, but I never make it!

Matt Bishop

#19

Posted 27 November 2018 - 01:55 PM

While a good flux is important, most racers soldering problems is caused by not having an iron that gets hot enough, or has poor recovery.

Nothing is better for it's size than the Hakko FX-601.

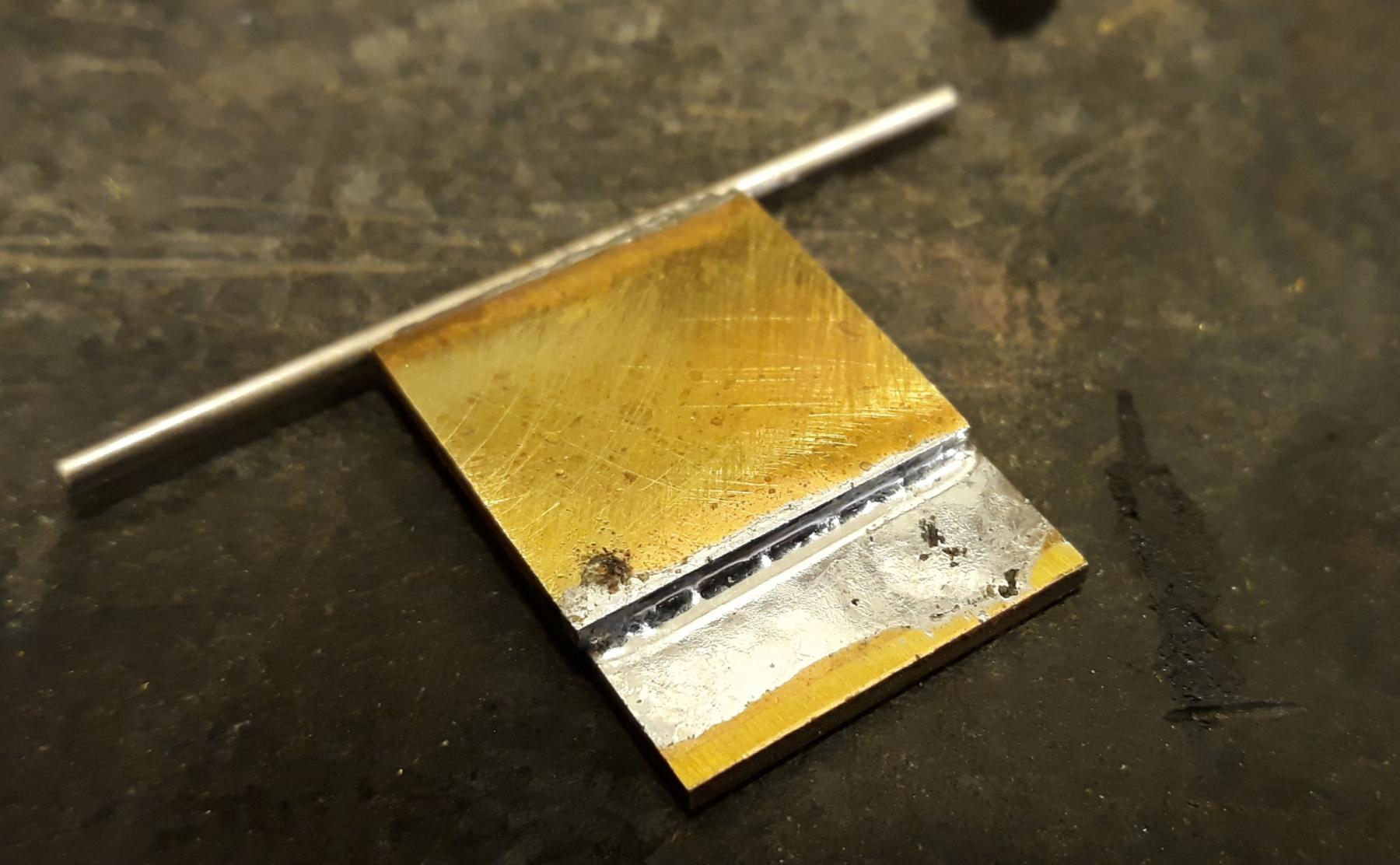

Here are some joints done with that iron and my flux.

All the joints took a matter of seconds because I always have solder on the tip for good heat transfer.

Attaching .062" brass to the the same. No trouble getting everything hot enough, quickly.

The ,molten solder was perfectly "welled", when I removed my iron, but it rippled up a bit while cooling.

The back side of the same joint. Note the solder flow to the end, across the width of the piece.

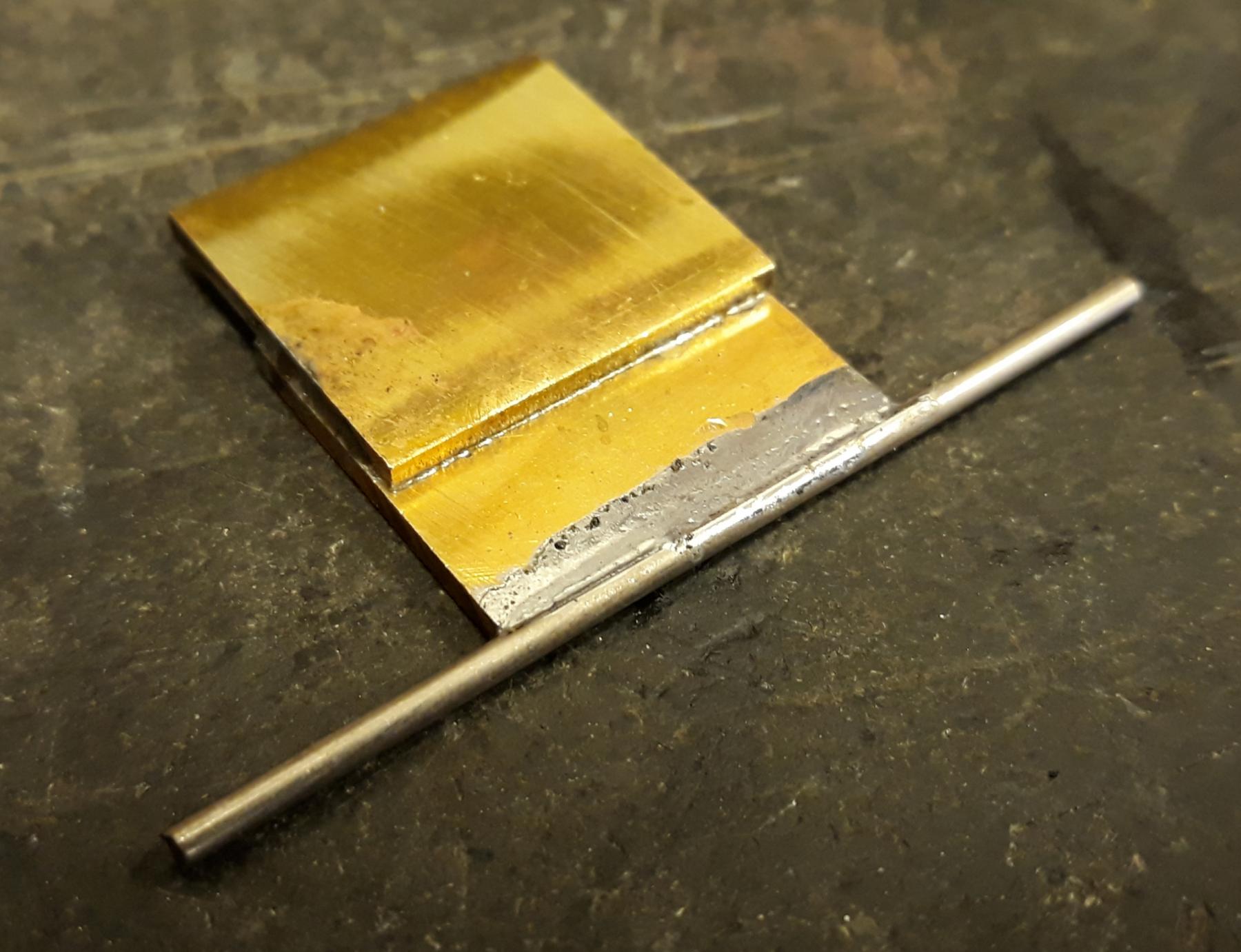

I also did a 2 second solder job, soldering a pc. of my plated .062" wire to the brass.

Addind a drop of flux, I took a quick swipe at the original joint, and got luckier while it cooled, and it is a little less "ripplely."

I chuck one end in a vise, grabbed the other end with a pair of linesman pliers, and broke the 2 pieces apart, to expose the fully flowed solder.

(Edit-those 2 small spots appear to be unturned brass)

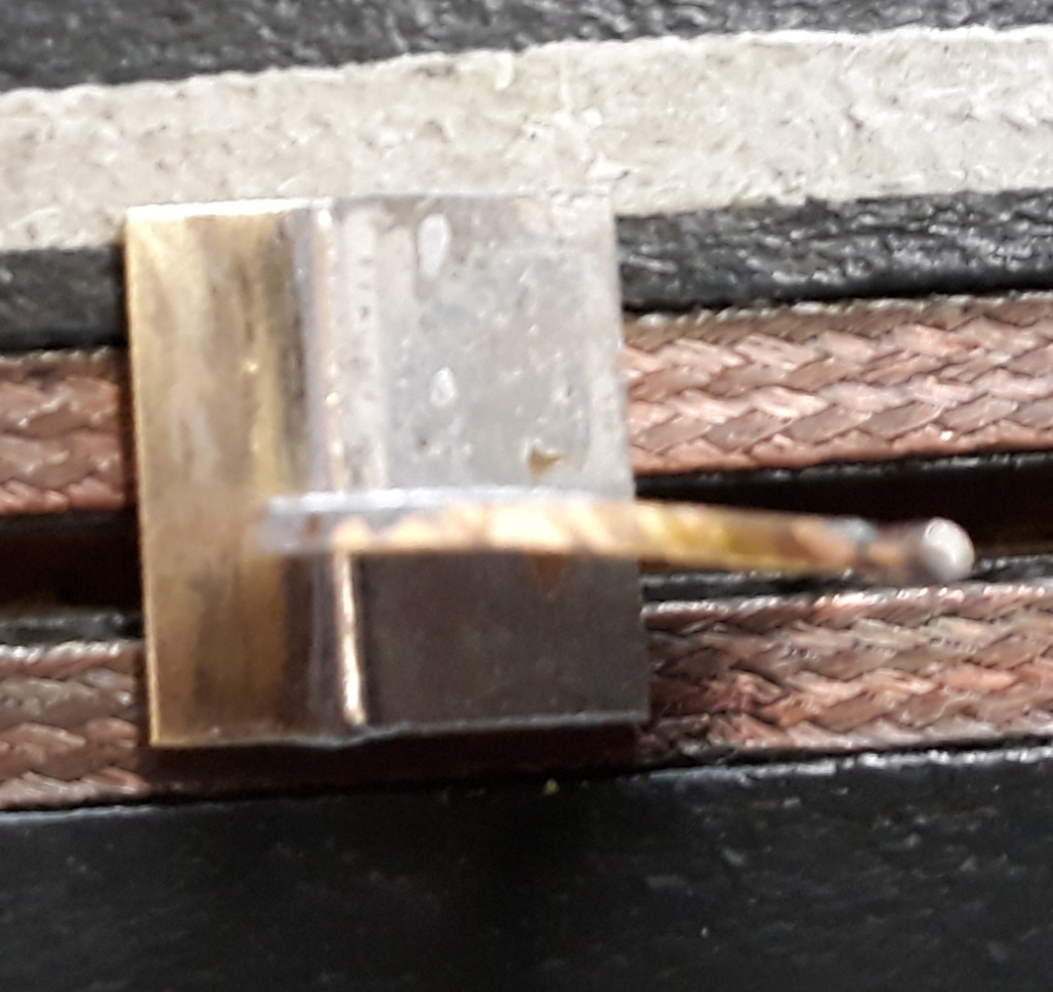

I was able to bend the super tough .062" brass, this much, before the solder sheared.

- tonyp, NSwanberg and MattD like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#20

Posted 28 November 2018 - 02:55 AM

the reason i like using a torch is i get full penetration in each solder joint. i'll tack the joint with just enough solder & reflow it with the torch. for the pin tubes, i'll tack the corners & use the torch to solder it all around. it's quick & easy with very little clean-up. I tinned the wire retainer on the bottom, dab on a little flux, hold it with an alum rod & torch it in place. as you can see, there's barely any solder & no clean-up.

First Place Loser in the JK Products

International D3 Builders Competition