Putting together another big block but decided to use one of two 36D arms wound for me by Champion 507 of this very blog, I just tied, epoxied and roasted them on the spit. They should be back from grind/balance soon.

I will be using his 60/28 arm on the left as opposed to his 75/29 on the right. The arms are wound with solderable wire rated at 155C and attached to the comm tabs with 95/5 silver bearing solder. Excellent winding job...

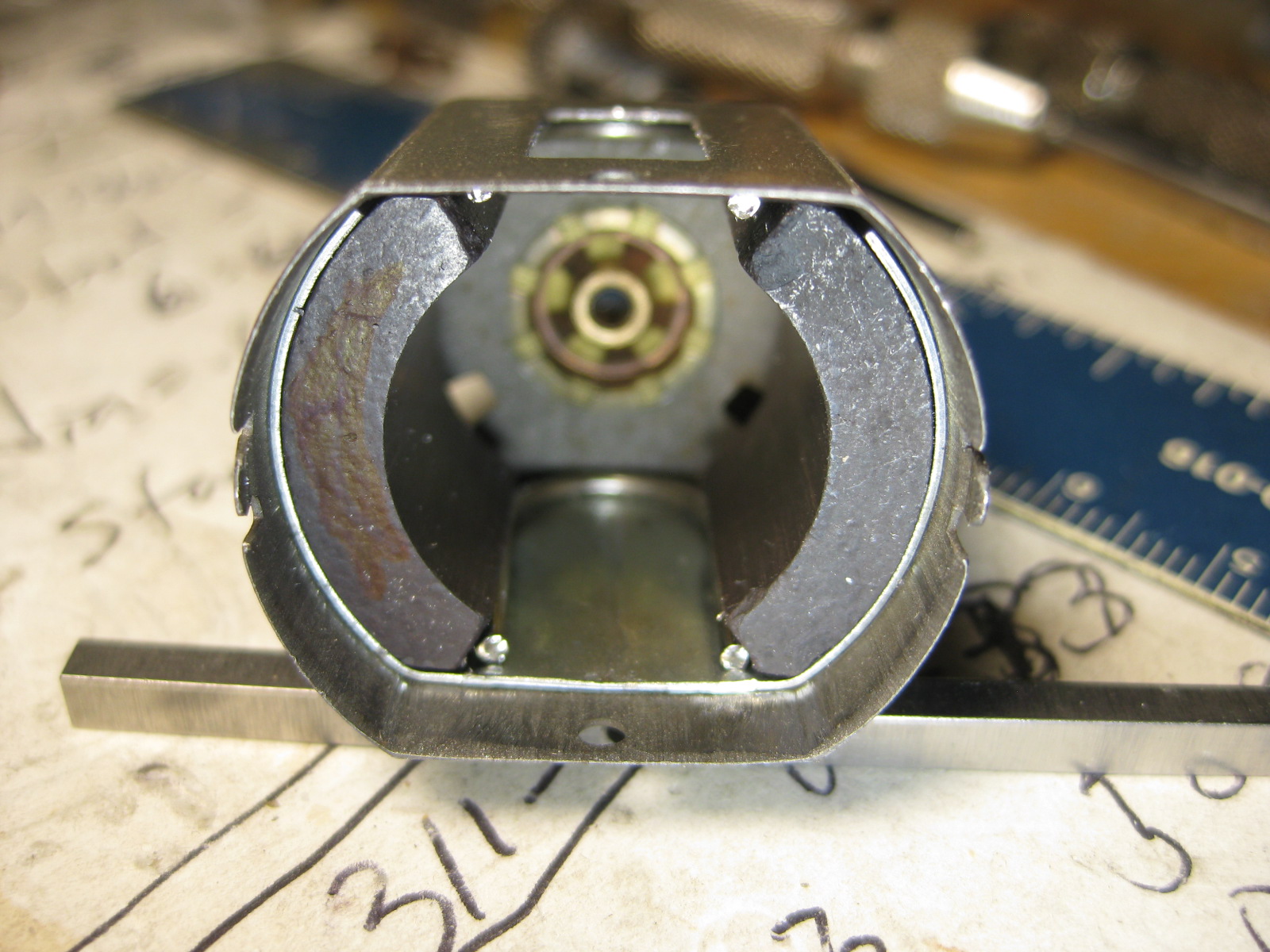

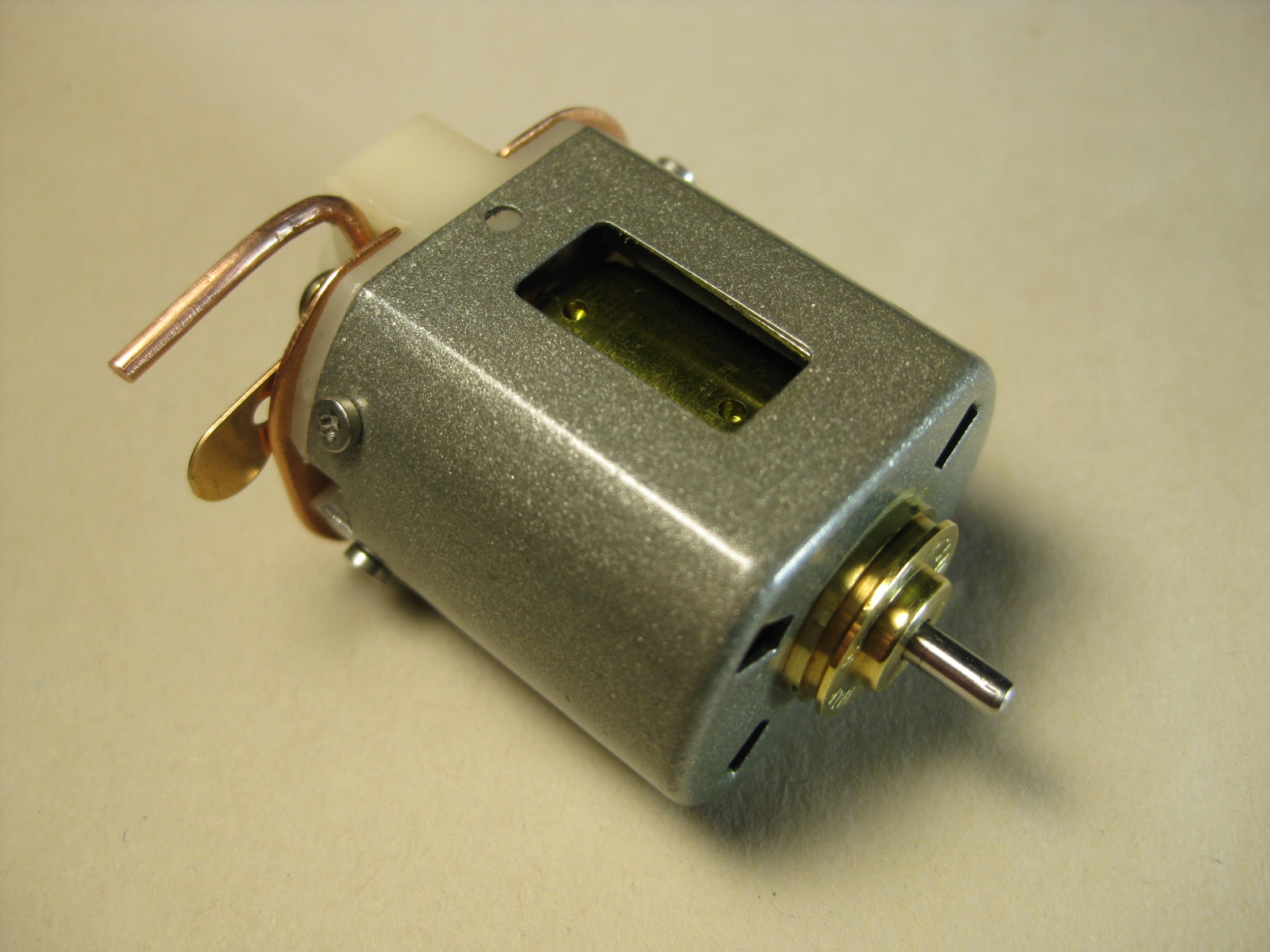

Remembered that I had a couple of 36D cans with totally dead Arco magnets. Pulled out one set of magnets and zapped them on a low carbon steel slug and presto chango we get about 1200 Gauss on the meter with the magnets back in the can. It took a 20 mil shim on the open side of the Arco flux yoke to center the magnets properly.

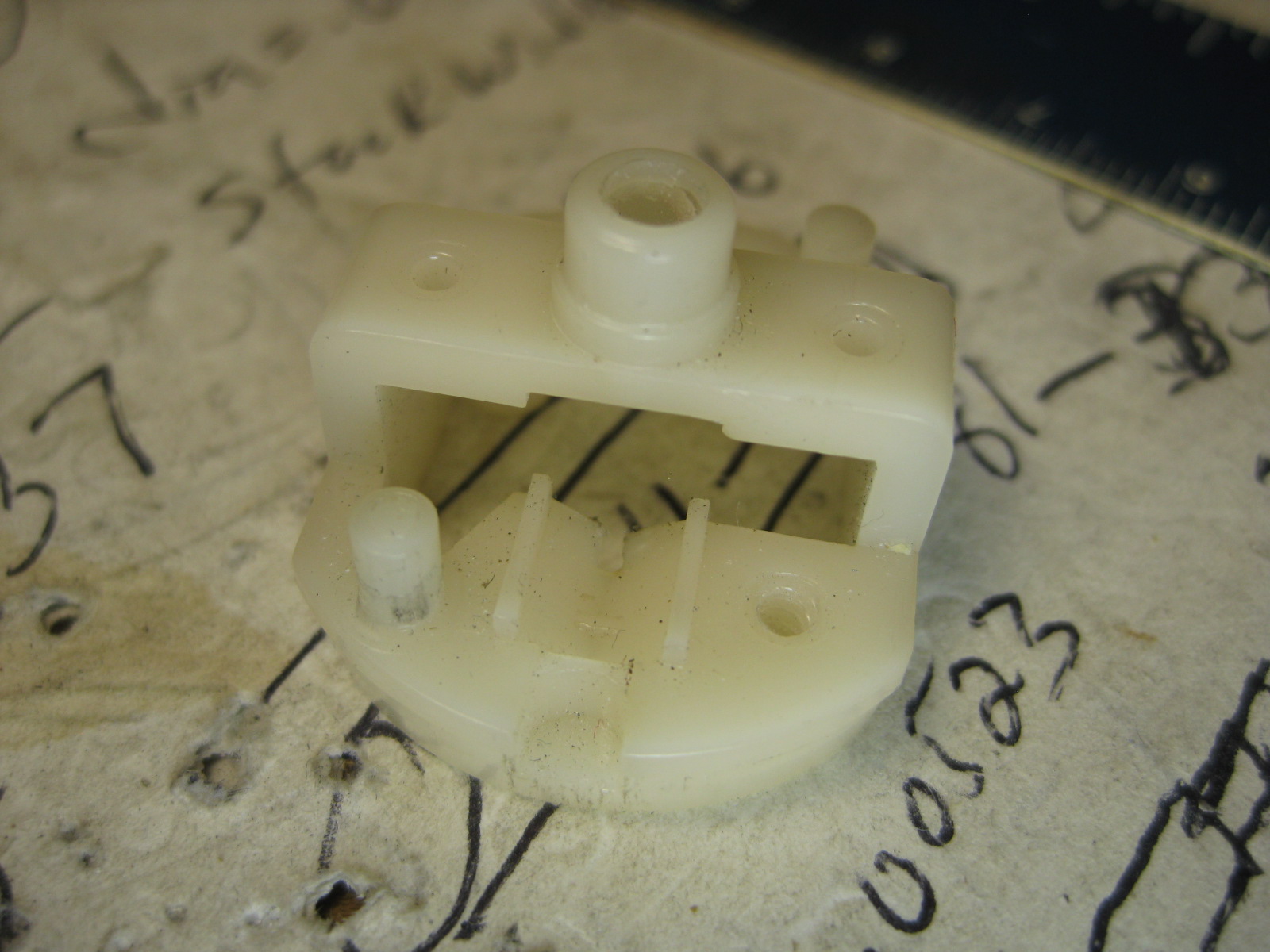

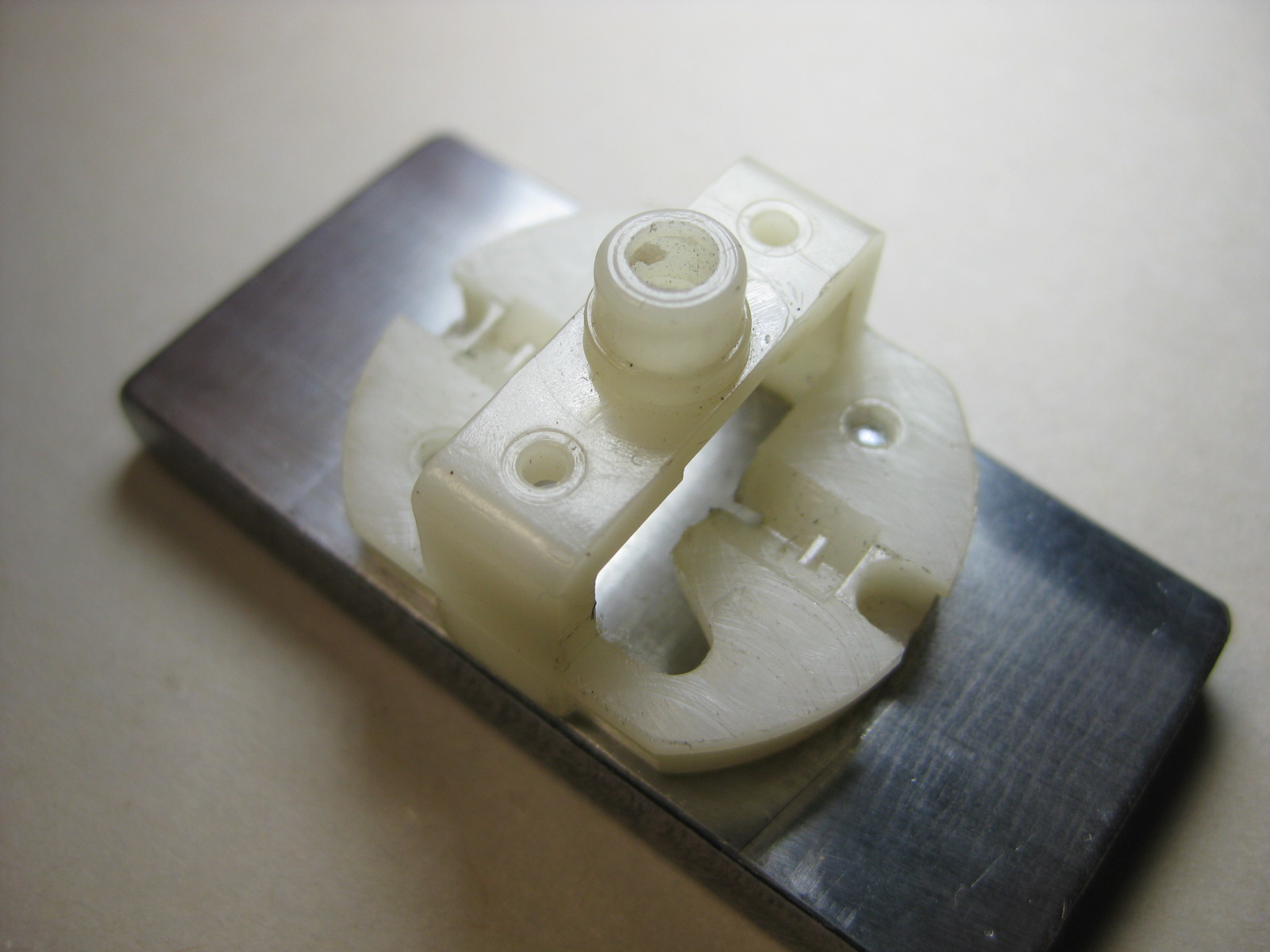

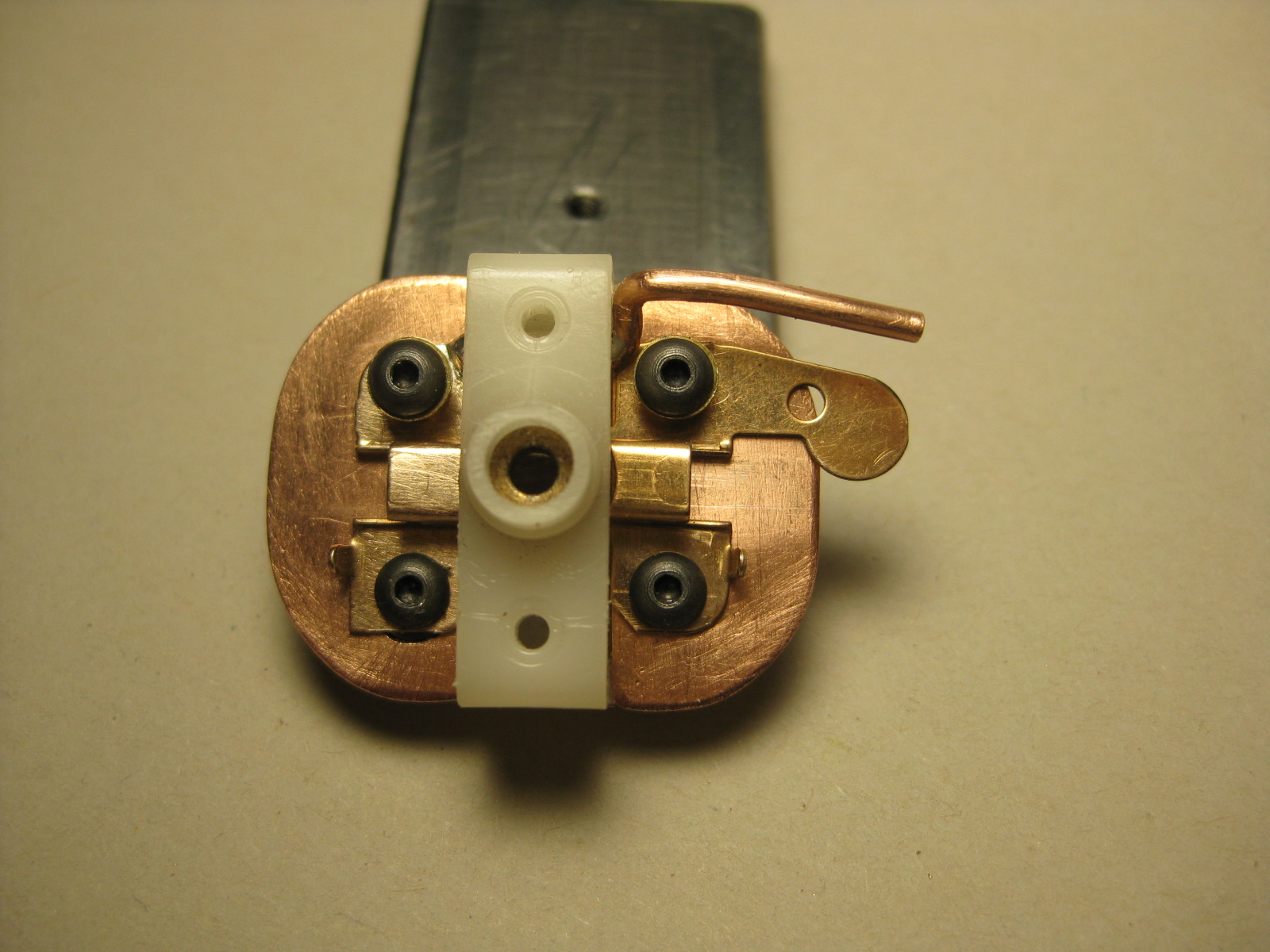

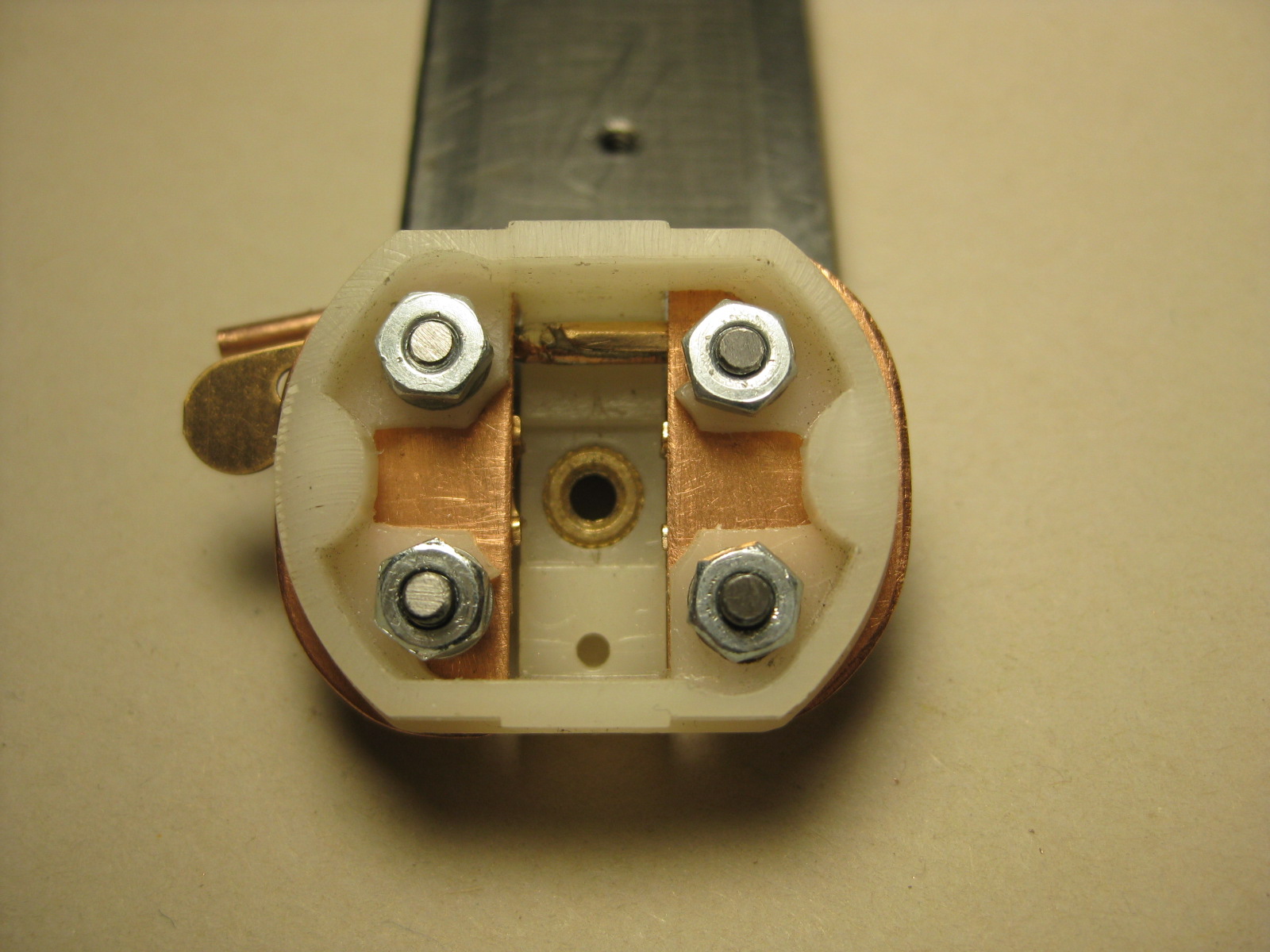

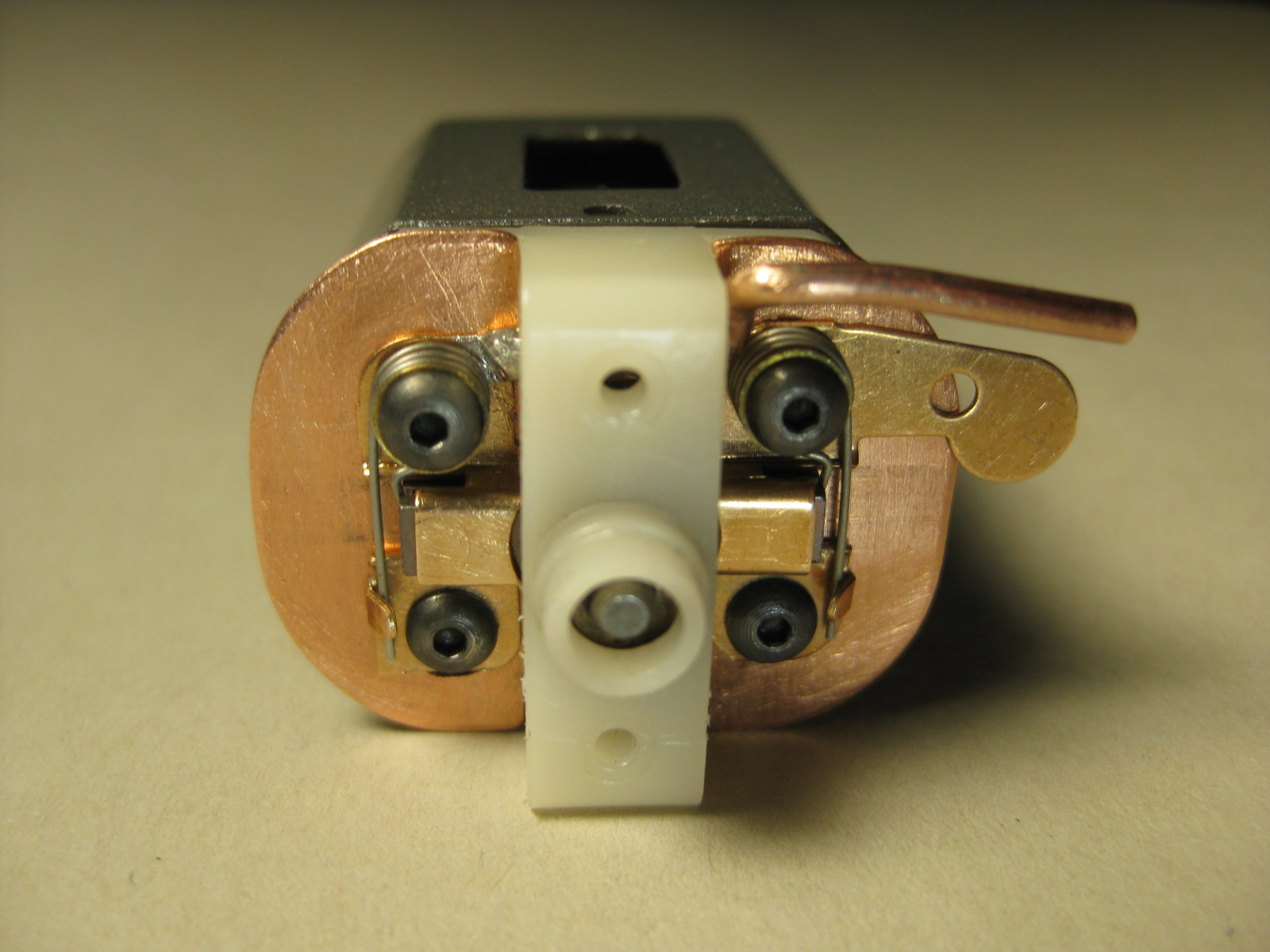

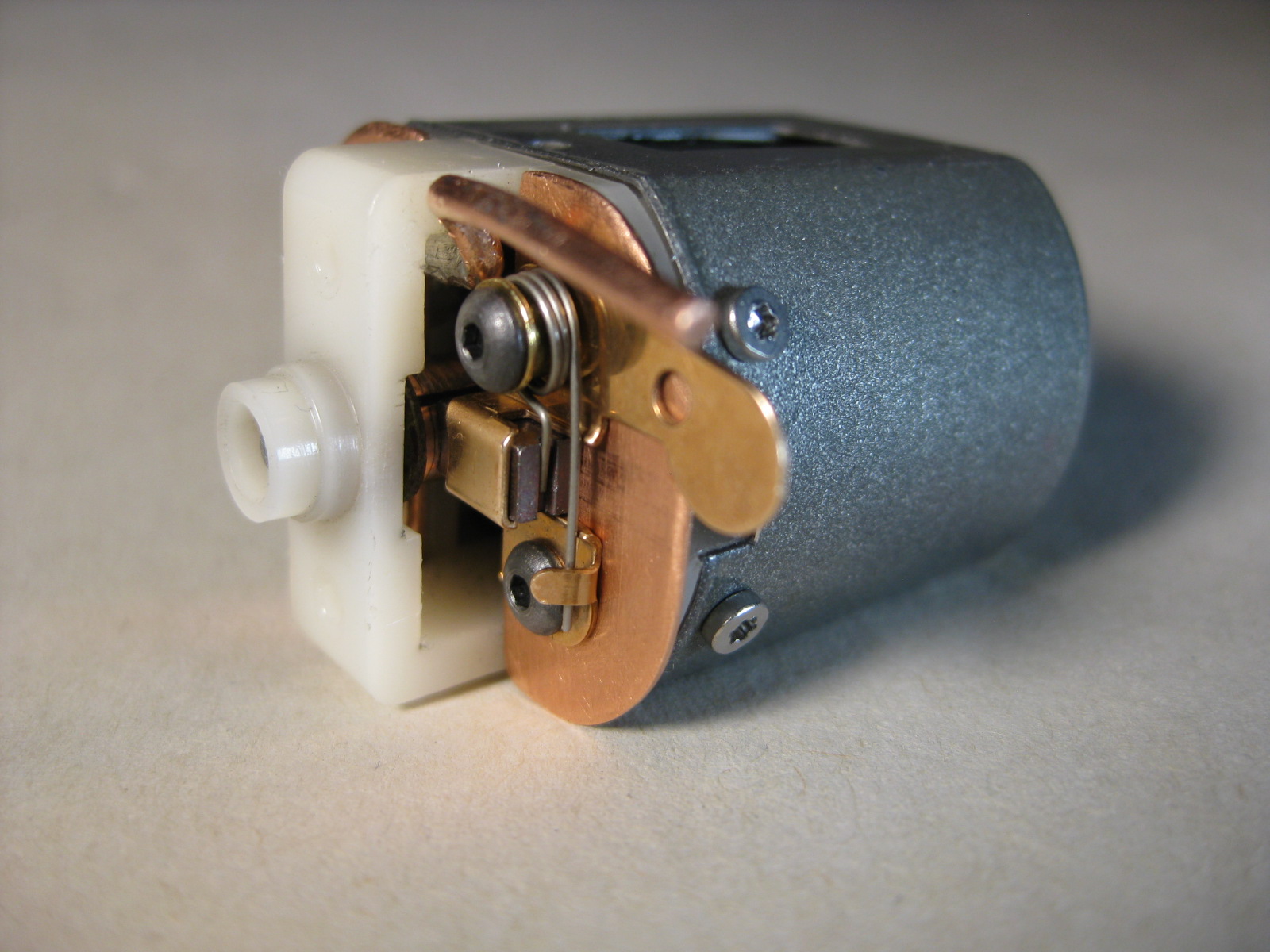

Not sure what kind of brush hardware to put on the end bell but there must be something somewhere...