I'm not positive but I've seen devices that count on eddy current damping in space-based mechanisms using copper plates moving between two un-powered field coils. When they flip a switch (that shorts out the field coil), the eddy current damping effect of moving the copper plate between them is profound, stopping the pendulum motion in less than two cycles.

Take-away - copper is NOT magnetic - it is only a conductor.

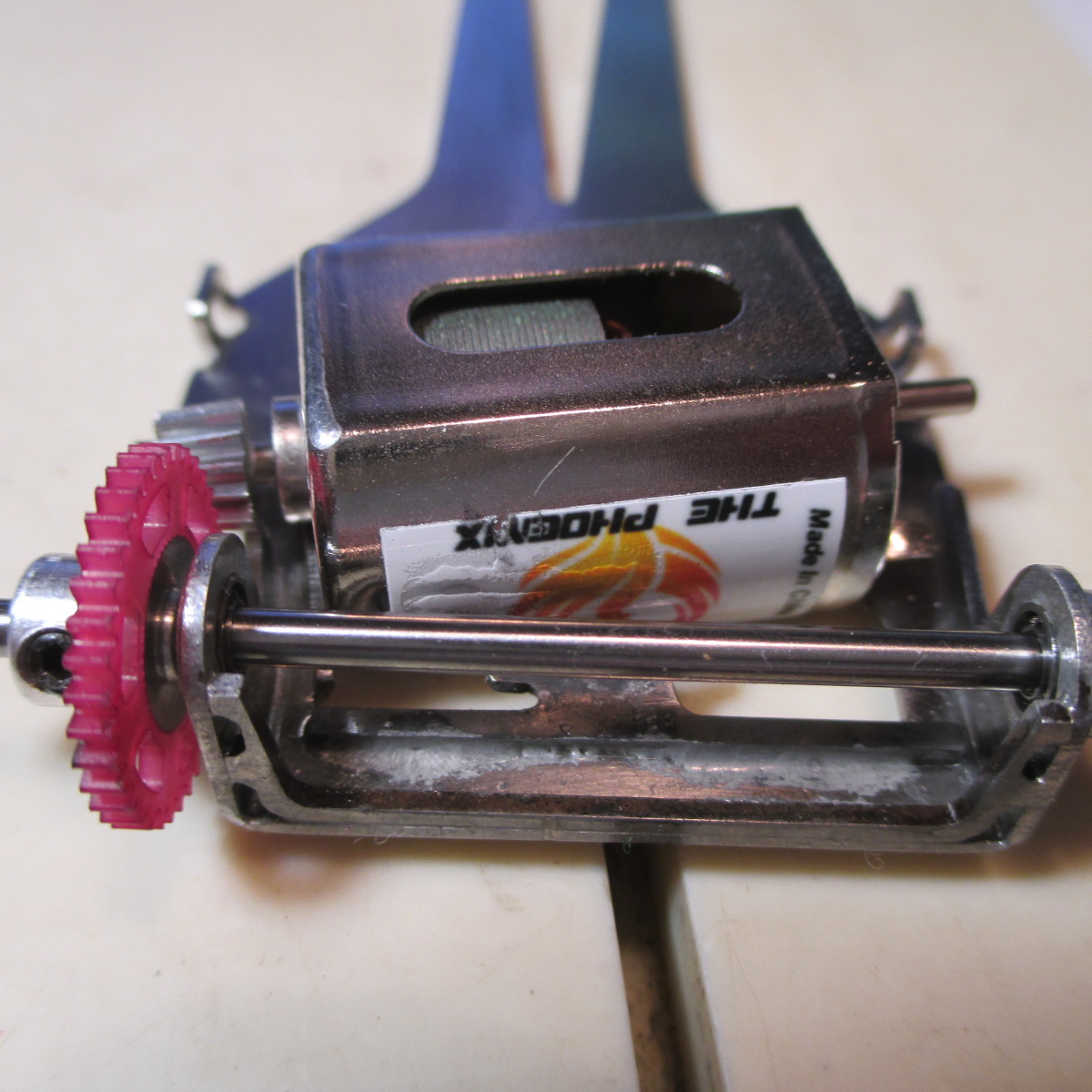

It makes me wonder about a rotating shaft (axle) within the magnetic field of a motor. I think the eddy current damping works on most any conductor and manifest the effect you are seeing in the test results. If these assumptions are correct, the damping would occur with ANY metal axle.

You may have also discovered that the effect is minimized somewhat with a hollow axle. Is that your take-away?

By the way, the hollow axle reduces the high CG (and rearward and overall) mass somewhat but the rotational (polar moment) inertia is a function of the 4th power of the radius, so rotational inertia benefits for an hollow axle is pretty small because the outer radius is what counts against you, not the core.

Bending stiffness decrease is minimal (function of the 3rd power of the radius) so crash damage due to bending resistance due to a crash impact is still quite good for a good grade of steel with proper heat treat. There is, however, a better chance of buckling at the point of resistance (ball bearing or bushing) but that is offset by the additional hoop support in the buckling area due to the inner ball bearing race or the ID of a small ID clearance bushing.

If the eddy current damping is really occurring, the no-load draw in amps might not be the best indicator of total torque power delivery to the tires while under load. but the damping IS proportional to the speed so there might be a top-end limiting factor, but that is also the case with the increased damping of the stronger magnets ...

Another thing to consider: I have been told that super strong track magnets on unlimited class HO cars expend a significant amount of their power overcoming the eddy current damping of the magnets moving relative to the rails. I'm not sure that the effect is actually a combination of eddy current damping and vastly increased rolling resistance of the tires with related increased axle friction.

Just my 40% of a nickel.

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"

![]()

![]() for a change.

for a change.![]()