I certainly have not posted many projects within the last year so this will be my first of the 2019 season. With the NorCal retro season fast approaching, this will also be the subject of some long term tuning.

It’s not that I hadn’t been building during ’18 but customer cars had me pretty busy much of last year and most of what I did for myself was small variations on existing stuff and I just didn’t want to repeatedly post up the “same old things”

This chassis is built from a newer R-Geo kit that has been released fairly recently. This is partially a rail variation of the “Razzo” but it does use an entirely new nosepiece. I believe that Mr. GVP was closely involved in the development and he has posted on this as well. I built this in "bone stock" configuration because the feedback has been very good. Rick B calls this the “X-Factor” kit and I think it is generally available now.

I really wanted to do a full step by step article but as I got into it, time got the better of me. It turned out that after a few detail steps at the beginning, all I had time for was some explanatory closeups after finishing.

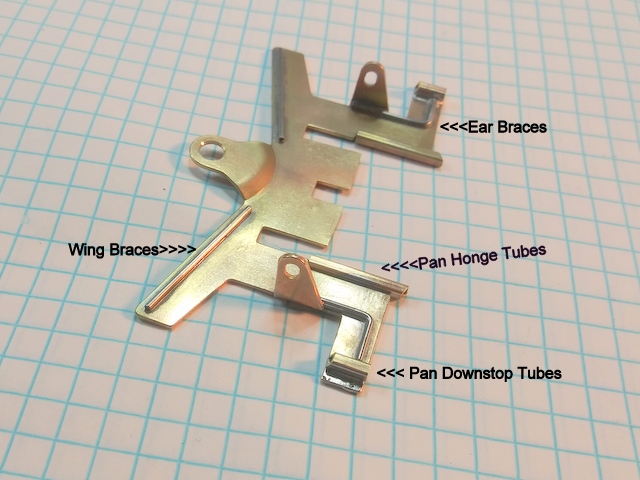

Here are the starting components.

Step #1 is always to detail the bracket. This shows the bracket face colored with marker and then filed until the face is flat to outboard of the screw holes……..almost there!

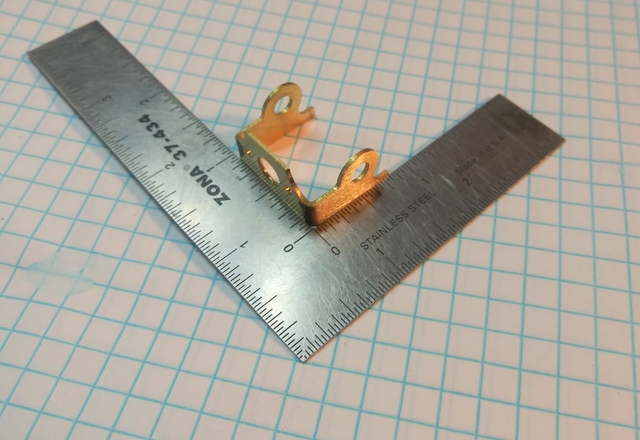

Squaring up the bracket

This shows the nosepiece details along with a potentially different downstop configuration. If using this setup, a stop rod would extend from the the pans into the downstop tubes.This just shows a building option. After this pic, I took this back to stock configuration using the formed in loops at the front of the pans and a piece of 3/32" sq. tube as the combo up/down stop. for this article.

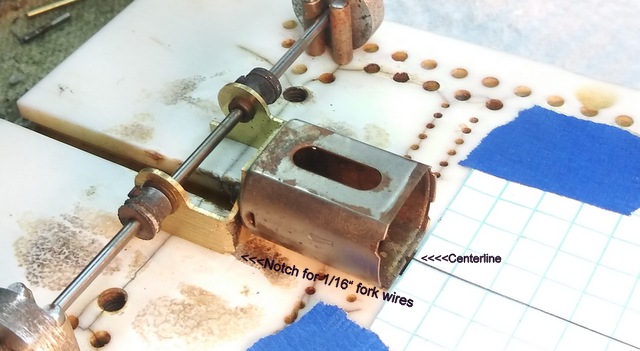

A piece of graph paper taped to the jig to aid in forming the tuning fork rails. The fork rails are .062.

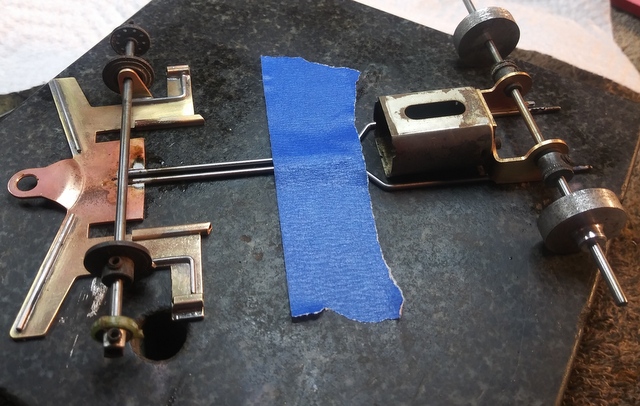

I started to realize my time limitations now so I have skipped over the bending of the fork rails (I’ve covered that before anyway) Here it is with the rails in place and taped to my granite surface block. At this point, I’m “relaxing” the joints by torching each of rear corners and the center attachment point for the forks to see if anything moves. After this step, everything should be flat.

From this point forward, I had to get it going so I’m going to show further details using the finished chassis.

- This chassis could be built with many configurations including variations of the fork and rail diameters.

- This could also easily be built as a straight rail car.

- In this case, .062 forks, >055 angled rails, 4" W/B, .925 G/L, 65 gr with "windows" in.

Front details:

- 3/32 sq. tube as up/downstop. Important to solder this on the ears not the pans.

- Front hinge rod is .055 in 3/32" tube. I tried .062 but it was just too tight.

- Small filler to take up the gap between the 2X.055 angled rails and the pre-cut rail slot.

- There are couple of additional axle uprights in place for bracing and a loop point for leadwires.

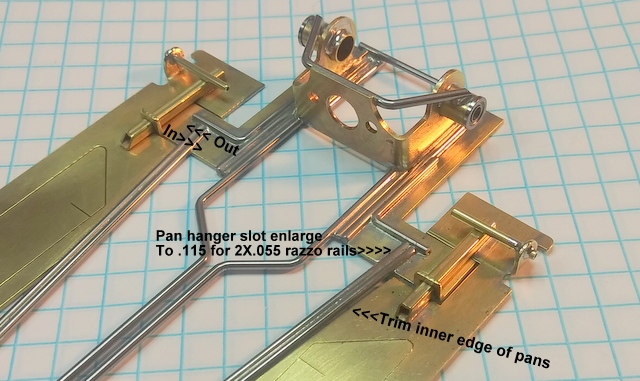

Pan hanger details:

- Rail slot needs to be enlarged for the 2X055 angled rails. Slot can be enlarged either inward or outward,

- If the slot is enlarged outward, as I did here, the inner edge of the pans will need to be trimmed to clear the rails.

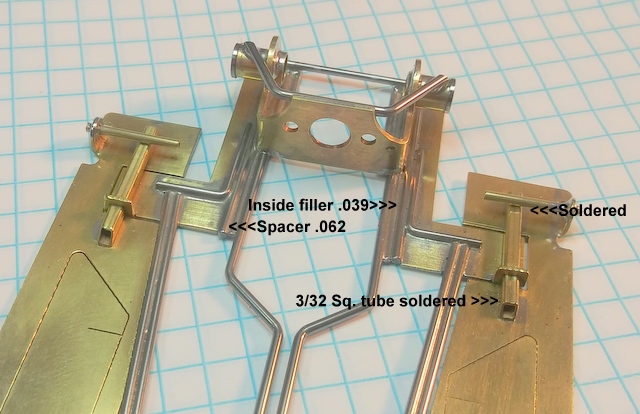

More hanger details:

- Small filler to compensate for thickness of bracket so that the spacer rail will be flush and runs all the way to the rear

- Spacer rail is .062 and spaces the pan hanger away from the bracket and to match the depth of the pan cuts.

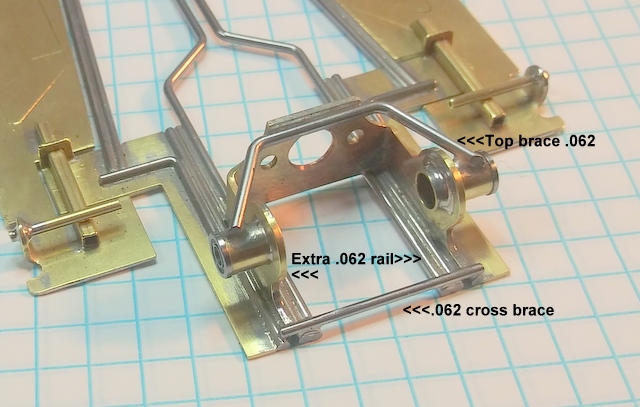

Rear View:

- Extra bit of .062 inside the bracket for additional soldering surface for cross brace.

- Cross brace self explanatory.

- Top brace is something I don't often do on a .050 bracket but did choose to do on this .040 one.

- Looking at the fillers and spacers from a different angle.

I'll set this up today and I really hope to travel to Motown this weekend to test it. I haven't touched a controller for a couple months so I'm kinda thinkin' that if I do go, it'll be a "rust chipping" expedition......... ![]()