Part 1: Drawing a Modern Slot Car Body in Tinkercad

In a previous post, Jan. 16, 2019, I described how I drew a simple 3D slot car body in Tinkercad, and sent it to Shapeways to 3D print. In that project, I created the body as a solid 3D object, which I hollowed out to create the underside of the body.

For this new project, I decided to try another method: Starting with a 3D model of the minimum requirements, I plan to cover the minimum shape with very thin, flat planks. Then I will delete the the minimum requirements model, leaving the assemblage of planks. By using this method, I will not need to hollow out the underside, since the underside is never filled in.

For this new project, I measured several of my wing car chassis. I wanted to design a body that didn't have to climb up over the front axle! With no front axle, the slot car body can rise gradually to the motor box and rear tires. Wing car chassis are anglewinders, so the motorbox is further back and wider. The wheels are also smaller than the previous design.

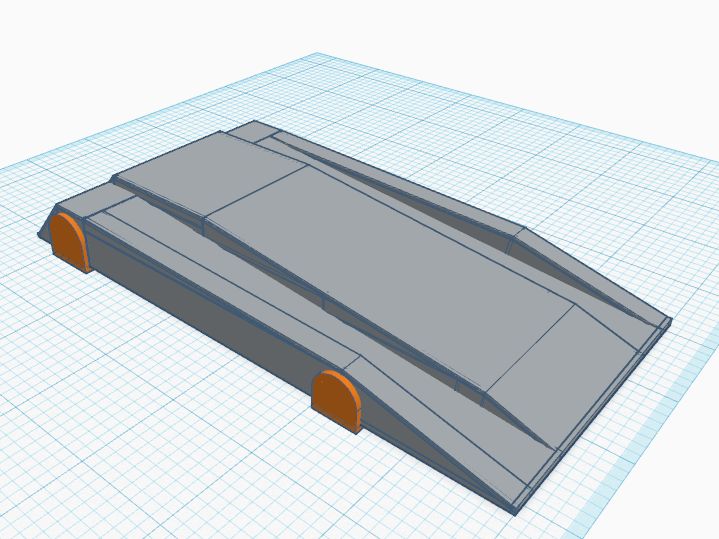

This image shows the 3D drawing of the minimum requirements, discovered by measuring several of my wing car chassis.

A CAD drawing tip: You can easily make a duplicate of your 3D drawing. Do it! I make a copy at every crucial stage. Then, if I mess things up, I have a back-up.

Here I am laying out the planks, 1/32" (0.78mm) thick, rectangles and triangles.

Setting out the horizontal pieces was fairly easy.

The outside vertical pieces were slightly more difficult, made of 5 combined, overlapping rectangles and triangles.

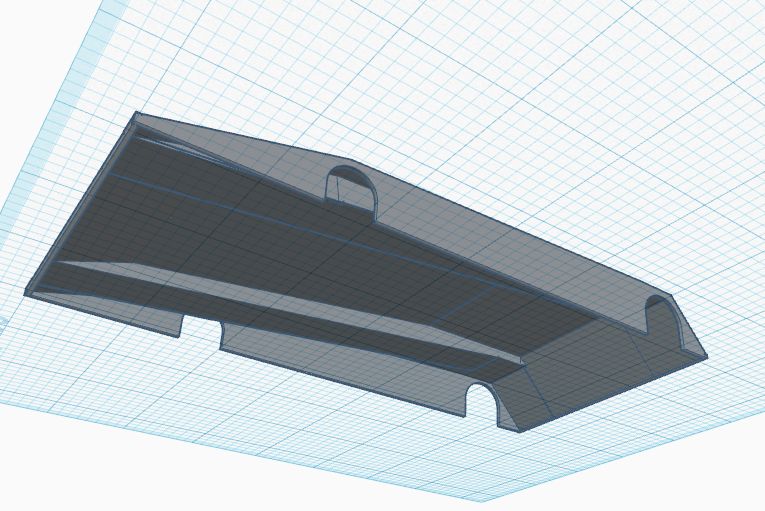

The interior vertical surfaces were much trickier. They must meet the horizontal pieces on both the top and bottom line. These pieces can not extend downward indefinitely into the hollow space below.

As you can see, these interior pieces had to be constructed of 2 and 9 overlapping pieces each, and fitted carefully into place. Luckily, when a panel is completed for one side, I can duplicate it, and fit it to the other side.

I cut holes for the wheel wells.

Here is the final design, ready to export as an .stl file, and upload to Shapeways.

Stay Tuned while I post Part 2, in just a few minutes.