Doing an FK drag motor...

#2

Posted 04 April 2019 - 06:48 PM

- havlicek likes this

#3

Posted 04 April 2019 - 06:49 PM

Now we is talkin...

- havlicek and C Gambo like this

Yes, to be sure, this is it...

#4

Posted 04 April 2019 - 07:05 PM

- havlicek likes this

#5

Posted 05 April 2019 - 05:15 AM

No specs to reveal?

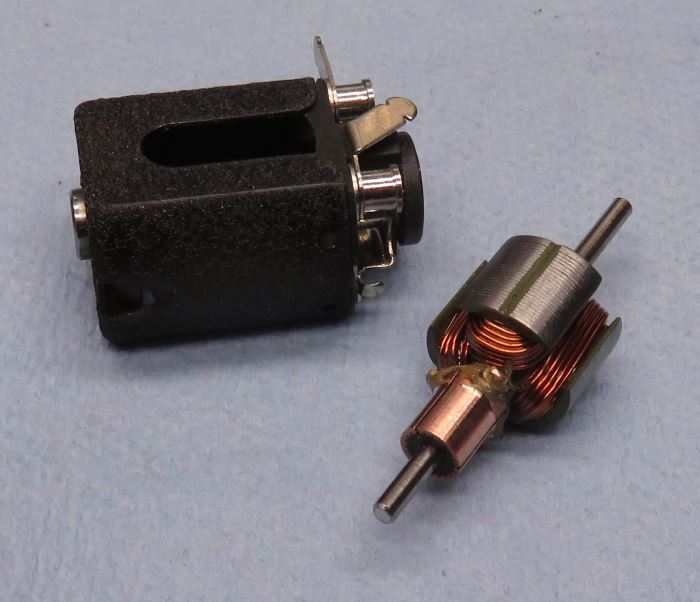

The can is...er...was a regular fk, cut down to around .750" and then had rear axle relief notches cut and the end flared a little. Leaving the basic factory hole alone makes for a better field. The magnets are ceramics from a minican, and here they measure as strong as they would in their original can...around 1150 on my meter, which puts them in general C-can ceramic singles territory. Both the can and end bell got bearings, with the end bell bearing keyed to the plastic. Armature is a 23/25 (*"35") with 30 degrees advance...I've been upping the timing on some motors because people nowadays seem to expect that, making for a very fast combination. With shunts added, I guess that the motor would be OK for some hot laps, but *I THINK* this would be best suited for drags, which seem to be more popular lately. If the motor were to go into a "hot lapper", a light piano wire perimeter anglewinder would make the most sense to me...but I'm funny that way. ![]()

PS: I replaced the stock phillips head end bell hardware screws with the dandy #0 black buttonhead screws from Bill Bugenis...MUCH better. I also opened-up the flange of the end bell that fits inside the can to allow for better airflow and cooling, along with opening the end of the can.

- olescratch, C. J. Bupgoo and Geary Carrier like this

#6

Posted 05 April 2019 - 10:45 AM

I knew it wasn't just a big wire fk, lots of extras in this build! Once again, awesome little package of power, and well put together.

#7

Posted 05 April 2019 - 11:16 AM

Thanks John. With the advent of the hot fk motors and especially the Hawk 11 meant primarily for drags, and as cool as those are, they're limited by their commutators. I don't know for sure what's "possible" direct from the manufacturers, but I think #25 wire would be out of the question...I think! I've done some of those with #26 wire for some experiments, and it was very difficult using silver-brazing, but maybe the factory might be able to make the connections using typical welded connections. In any case, an armature spinning this fast would likely mean a really short life for those coms and brushes. Last, I'm still partial to the ceramics over the various neos, and the ones from the minican motors work especially well in a fairly "closed" design "fk", but all of these things can benefit from better airflow, so I tried to walk the line here between field strength and airflow. It would still be cooler to have cobalts, but that ain't happenin' !

- olescratch likes this

#8

Posted 05 April 2019 - 12:19 PM

Check out the Proslot catalog and the 'Velosiraptor' series of drag motors.

Larry D. Kelley, MA

retired raceway owner... Raceworld/Ramcat Raceways

racing around Chicago-land

Diode/Omni repair specialist

USRA 2023 member # 2322

IRRA,/Sano/R4 veteran, Flat track racer/MFTS

Host 2006 Formula 2000 & ISRA/USA Nats

Great Lakes Slot Car Club (1/32) member

65+ year pin Racing rail/slot cars in America

#9

Posted 05 April 2019 - 02:18 PM

Check out the Proslot catalog and the 'Velosiraptor' series of drag motors.

Unless they've changed, I've seen them and they've been around for a while now Larry, so yep, I'm aware of them. Those do not use the typical Chinese type coms or arm laminations. Also, they aren't fk motors...but they would more closely align with this motor anyway as it has a removable end bell. Neat motors...pricey but neat!

#10

Posted 06 April 2019 - 06:06 AM

To be a little more clear, I think the fk, once modified for an end bell, makes for a better can than folded-and-welded minicans like the ProSlot. They are significantly stronger where it really counts, and still make for a strong field, while being just as compact (*actually slightly more compact, but not enough to really mean anything). I know that the minicans, and all the folded-and-welded larger C and D cans are popular and proven designs, but the fk has advantages. It all makes me wonder why, instead of doing the minican, they didn't just modify the tooling used to produce the fk for a shorter version that would fit an end bell. There probably are good reasons I'm sure.