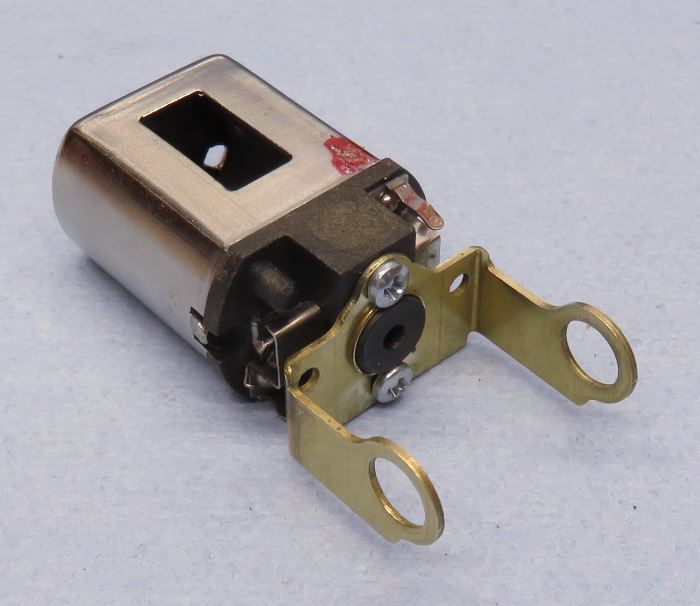

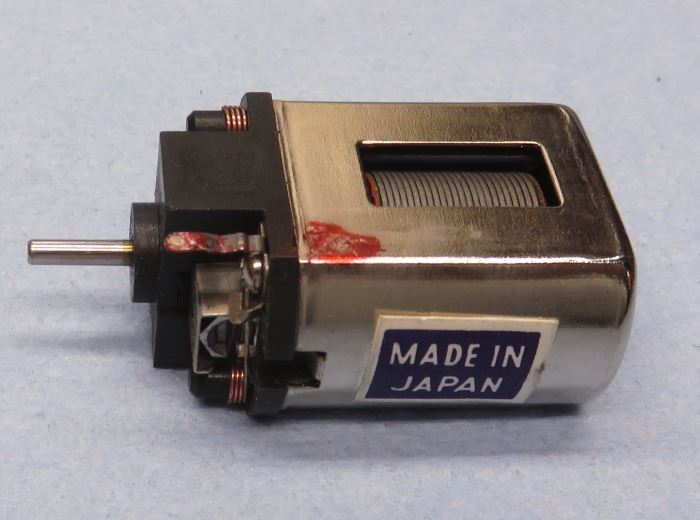

I don't know if this motor was for slot cars, but without any obvious way to mount it (aside from a hold down clip), this one doesn't seem as though it would have been. There aren't even any mounting holes in the end bell. It's also something of an "in between" variant. While it says "MADE IN JAPAN", the end bell is clearly of the type used in the Hong Kong produced motors.

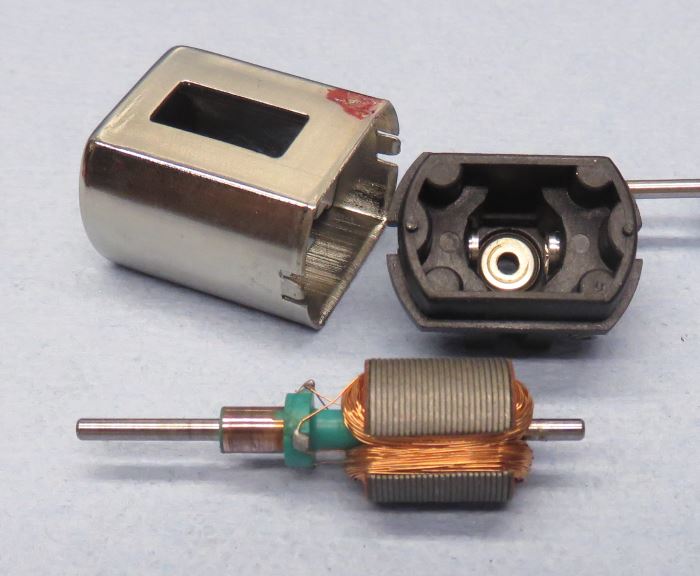

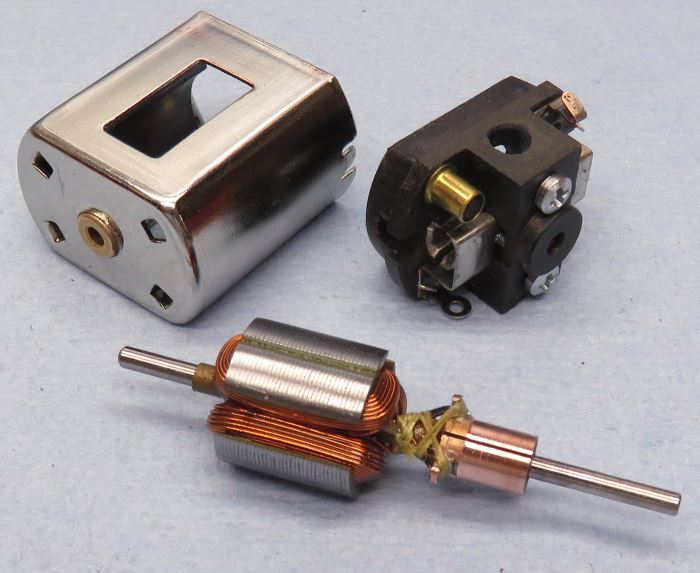

When you open it up, what you find is a typical Mabuchi/Japan armature would with what looks like around #33 wire. The armature has the fiber stack end insulators, as opposed to the coated stacks in the Hong Kong motors, So, essentially, this is a "Russkit 23" with a better end bell and a plated can as opposed to a painted one...and a different wind of course. By carefully prying the can ground strap away from the can and bending it forward, you get a perfectly acceptable lead wire tab.

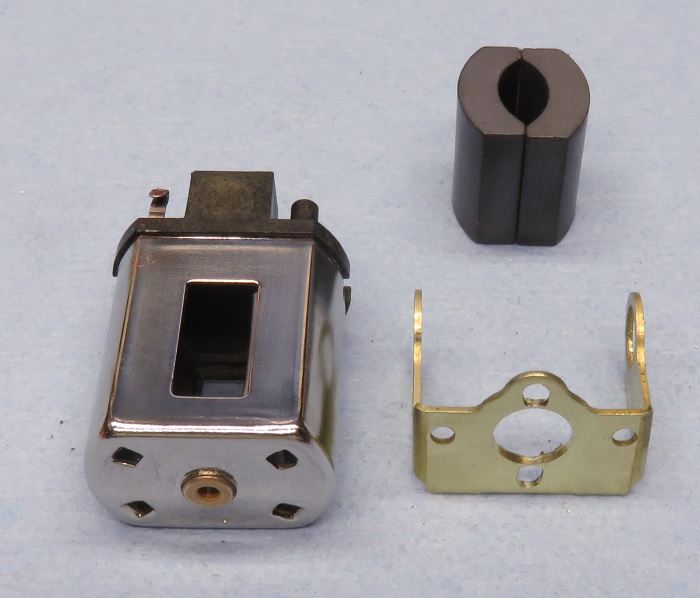

Opening it up, you find a typical Mabuchi "bearing" in the end bell...along with typical Mabuchi magnets. The com is also of the same type as the earlier Japan-produced Mabuchis...so this seems to be an "in-between" motor. Maybe it was produced later during the time when Mabuchis were made in Japan and before they were produced in Hong Kong...but who knows? Anywho...all the stuff you need to make a lovely period-type motor is there, except that a period-type bracket would need to reamed-out to fit the larger "Champion-sized" end bell bushing carrier, and a set of holes drilled for mounting.