I've mentioned this here before, but I figured I'd add some pictures and explain a little more. Instead of (*or in addition to if you're really dilligent) soldering the hoods on the various Mabuchi motors, I started epoxying/keying them to the end bell plastic. I drill a 1/16" hole in the bottom of the V-groove the brush tubes sit in, put some JB Weld in there and shmoosh the tubes in pace with the hoods. This should prevent the brush tubes from rotating as they sometimes do, AND it puts a barrier of much more heat-resistant material (JB Weld) between the brush tubes and the end bell plastic. Epoxy is a very good insulator as well, so a third thing is that the heat of the brush tubes is bound to be not as directly passed to the end bell.

So, here's a nifty Champion that got one of my C can shims and some hefty magnets, as well as a mondo inspection, ventilation, oiling hole...oh and bearing adapters at both ends:

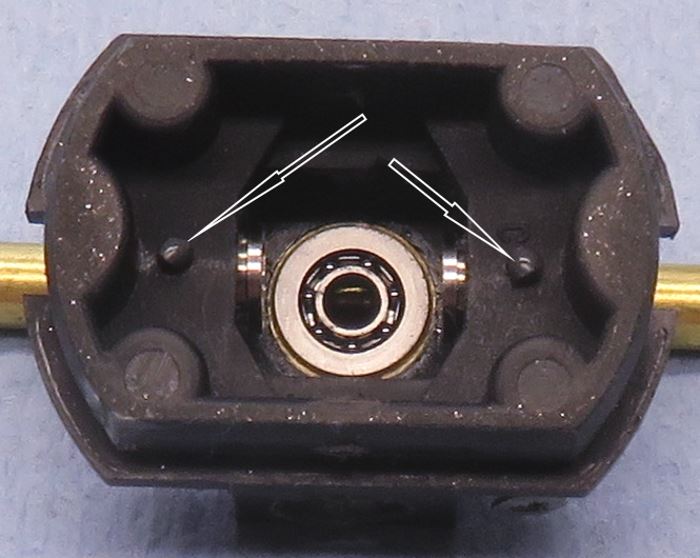

Here's an inside shot of the end bell with the JB Weld having flowed through the holes and sticking out through the inside. **It doesn;t really matter that the epoxy isn't going to bond well to the plastic because it WILL bond to the brush tubes, form a perfect fit between the tubes and the plastic and then form little keys that show on the inside to help keep everything locked in place.

Mabuchi endbell tweak

#1

Posted 01 July 2019 - 04:30 PM

- slotbaker, Pablo, Tex and 6 others like this

#2

Posted 05 July 2019 - 11:50 AM

Hi John,

That is one gorgeous and sinister looking motor - does this even make sense?! LOL

Mabuchi endbell tweak

You just like to "tweak" things John - and I'm sure the brethren feel the same as I do . . . that we like it . . . ..alot! ! ! ! hahaha

Thanks for sharing John!

Ernie

- havlicek likes this

#3

Posted 06 July 2019 - 05:26 AM

You just like to "tweak" things John

Hi Ernie,

Of course that's true Ernie, but I like problem-solving even better. With the Mabuchi end bell "hoods and brush tubes" arrangement, there are two main issues:

1) Of course, the end bell material is a major problem. The traditional "fix" is to solder the hoods to the tubes, and that's difficult with the "pentroof" hoods, but even more so with the "flat" type. Of course, it really doesn't do anything to prevent or mitigate the brush tubes from melting the plastic they sit in, it only sort of keeps the brush tubes in place as the plastic underneath them softens. With the "Hong Kong" FT160 end bell, this isn't really an issue as the end bell material is much more durable and heat-resistant...BUT...there's another issue as well.

2) The brush tubes themselves are not really well-located, or solidly held in place. I've seen enough of these motors where the tubes have actually rotated, to know that this is an issue as well...but I think this also happens as a result of the plastic they sit in softening with heat...I think.

Bedding the tubes in epoxy and drilling holes underneath them for the epoxy to flow into and through, puts a layer of MUCH more heat-resistant material between the tubes and the end bell plastic. The epoxy is also a very poor conductor, so it should provide some heat insulation between the tubes and the end bell. Drilling the end bell so the epoxy can squeeze through should also locate the tubes about as solidly as is possible.

Now, if this were the 1960's and these motors were being raced hard, it probably would be a good thing to do both the hood-soldering AND the epoxy bedding. Even a #29 wind in these motors is fairly serious business, and I can only imagine that racers back then were "up against it" with these motors, trying whatever to get them to go fast and to last...at least long enough. ![]() At least, it couldn't hurt and I sometimes do both just for giggles, but I think *only* bedding the brush tubes is probably as good or better insurance as soldering the hoods.

At least, it couldn't hurt and I sometimes do both just for giggles, but I think *only* bedding the brush tubes is probably as good or better insurance as soldering the hoods.

- Alchemist likes this

#4

Posted 06 July 2019 - 09:56 AM

Hi John,

Many thanks for the tech info - it's appreciated!

May I ask you, from your experience and observation, who makes the best quality endbell to date please?

I'm going to refer to endbells that you would employ when transforming FK130/C-cans.

Thank you John.

Ernie-130

#5

Posted 06 July 2019 - 11:44 AM

May I ask you, from your experience and observation, who makes the best quality endbell to date please?

I'm going to refer to endbells that you would employ when transforming FK130/C-cans.

They're all good...for the fk motors, I prefer the JK end bell's longer tower. For C-cans, whatever is out there is fine. I like the ProSlot, but the Koford one seems OK too, although kinda flimsy. For any motor that they can be had to fit, aluminum end bells have advantages over plastic ones, but are a little more fidgety to assemble. To me, the hardware is often more important than the end bell itself. I think the older ProSlot copper hardware was better than the new stuff...plated or copper. The Koford hardware seems very nice.

#6

Posted 08 July 2019 - 11:13 AM

Thanks John - it's appreciated!

Ernie