I finally grew weary of my 4" cast iron Harbor Freight "sloppy" vise.

It served its purpose, but it was always a handful to keep the motor/pinion in proper alignment because the sliding jaw had too much play.

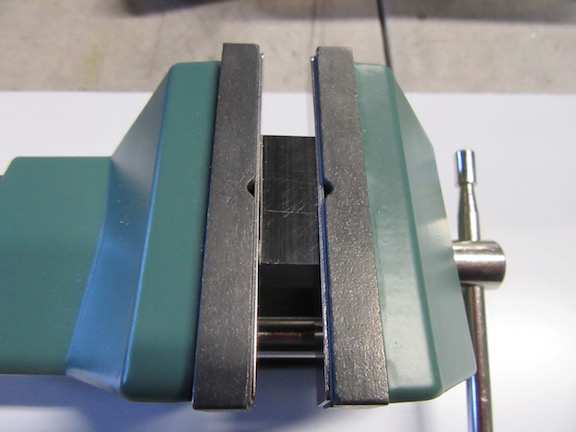

You can see how much "slop" there is in the sliding jaw

It would shift to one side (like the photo) when pressing on the pinion

It's heavy too!

Weighing in at 6 pounds!

I wanted a new "Pinion Press Vise" that was lightweight and compact, that I could carry in my box.

I had been searching for small size vise and decided on this 2-3/4" articulated vacuum vise from Harbor Freight.

I felt it was a good purchase with a 20% discount coupon - out the door for under $13!

The body is made of aluminum with a nice smooth casting and paint finish, and comes with "steel" jaws.

I've started to disassemble it -I won't need the vacuum base.

Four corner screws and a center screw attach the Jaws to the vacuum base.

It also comes with soft rubber jaw pads - which I felt was a nice addition.

The Jaw housing won't remain upright, so I made a pedestal from 1/4" thick, high-density polyethylene (HDPE) sheet

Though the jaws are steel, they had the screws countersunk, which left stepped holes, and also holding grooves.

I wanted a smooth flat surface, so I took some old, thick, feeler gauge blades and stuck them on the jaws.

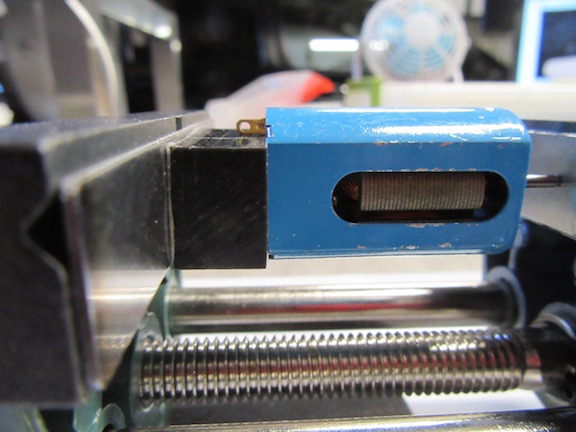

I also made a Delrin adapter block to retain the motor in position, for both double shaft and capped end motors.

The adapter block has a 1/4" hole drilled down about 1/8", it also has a 2mm hole (you can't see it) drilled all the through to accommodate motors with double shafts

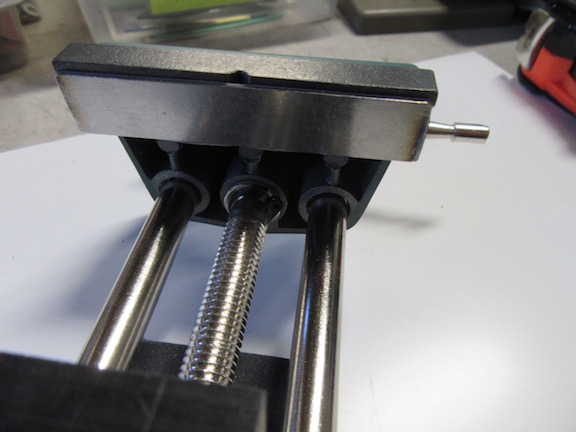

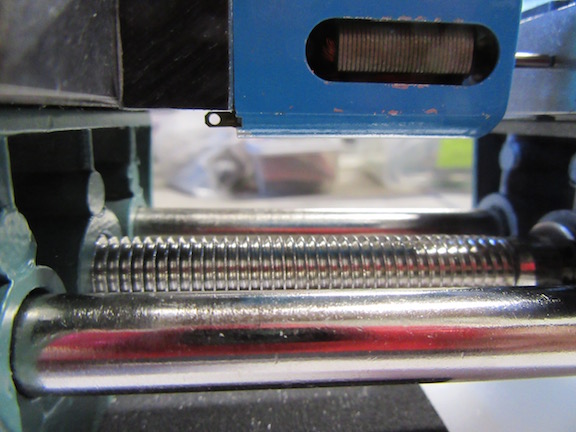

Here you can see that the Jaw slide has supporting rods on both sides, to keep everything in parallel - helping prevent the jaws from going askew.

Motor in place and aligned

Pinion ready to press on

Worked well!

The type of motors I was referring to.

Here you see how the adapter block fits in between the connector tabs.

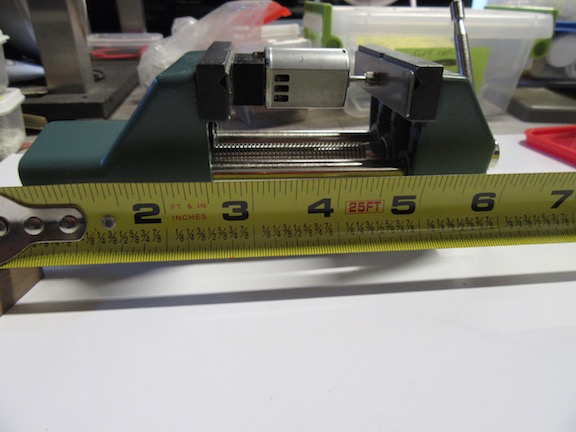

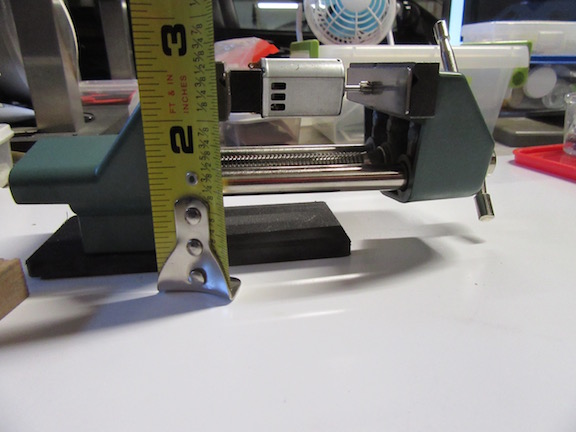

It has a small footprint!

6 inches long

2-1/2" tall

2-3/4" wide

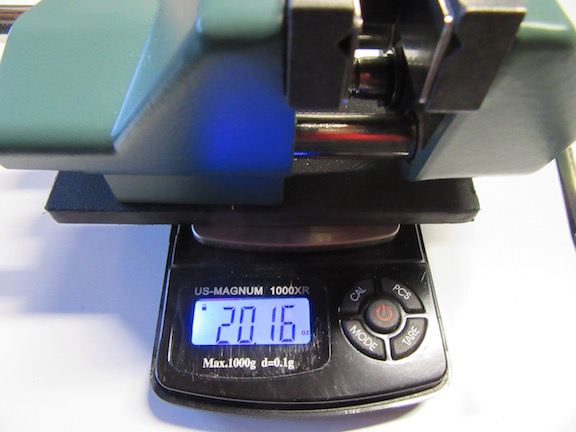

Very light compared to my 4" cast - 6 pound iron vise.

20.16 oz = 1.26 lbs

I'm pleased with my new Pinion Press!

Thank you.

Ernie