I use an engineering rule to check for flatness

Ok, cool.

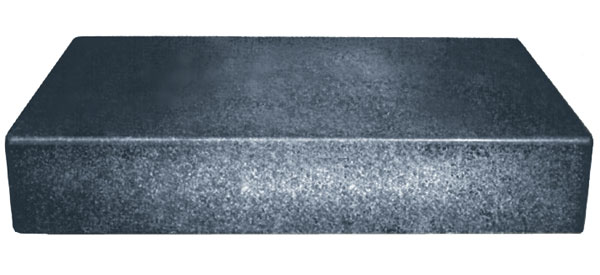

I'm guessing that if you checked the plate with the straight edge prior to smoothing it out, you would be hard pressed to get your thinnest feeler gauge (0.0015"?) through any gaps. If the milling is done correctly, the surface would be flat enough for our slot car use, even though it looks rough.

If you're interested in being super precise, and seeing as you have 2 flat aluminium plates, you could go one or two steps further to see how flat they really are.

As a rough test, put both plates together against the smoothed faces, and hold up to the light to see if there are any gaps between them.

If no gaps, good, then try the next check.

Get a small tube of Prussian blue oil paint from an artist supply store (or you might even already have it), and put a thin, even film completely over one of the plates smoothed face. Not too much, just enough to colour the surface.

Then put the second plate face down on the blued face and gently push down evenly then move the top plate in a figure 8 a couple of times over the bottom one, then check where the blue was rubbed off the bottom one, and deposited to the top one.

If there are high spots, you could lap the plates together with fine valve grinding paste, and check by blueing again.

Not sure all this effort is warranted for slot cars, but there might be some who want to be sooper accurate.