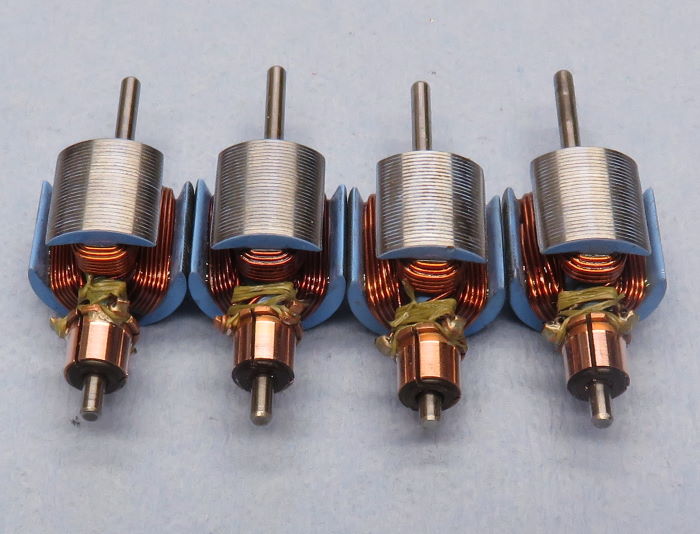

Here's a lovely bunch of coconuts headed for The Land Down Under after balancing. From left to right, there's a #25, a #24 and two #23's...with the 23 wire arms destined for a setup with those crazy-strong solid neos in quad confirguration. It takes real effort just to insert and remove the arms for spacing in that thing.

Anyway, I used the large coms marketed under various names...maybe produced by Kirkwood. They are really the strongest easily-available coms for this sort of use. They do have their own difficulties, mainly because of their short length, and using them means a good deal of internal clearancing on the end bell is necessary, but they are strong alright.

Ft36D's never die, they're often reborn as drag motors.

#1

Posted 23 November 2019 - 12:51 PM

- slotbaker, hiline2, Peter Horvath and 7 others like this

#2

Posted 23 November 2019 - 01:04 PM

Those comms braze nicely too.

Sweet selection of heat John... ![]()

- havlicek likes this

Yes, to be sure, this is it...

#3

Posted 23 November 2019 - 01:41 PM

Thanks Geary. 10-4 on the brazing. The shell metal is so thick that it barely gets warm while the tabs are being brazed. Besides how short these are, they're pretty fat as well, which is not necessarily a bad thing on the FT36D, since the gap between the back end of the brush tubes and the com surface becomes smaller. The slots on these are very wide, but you take what you can get when dealing with decades-old motors that have a bizarre shaft diameter. The Mura/Kirkwood coms can be reamed to fit, but that can weaken them a little and I don't have any lying around anyway.

- Geary Carrier likes this

#4

Posted 23 November 2019 - 07:58 PM

#5

Posted 23 November 2019 - 10:07 PM

#6

Posted 24 November 2019 - 12:47 AM

Hi John,

Those "quadruplets" are identical!

How does one tell them apart?! LOL

They are stunning John - excellent work!

Thanks for sharing.

Ernie

- havlicek and Geary Carrier like this

#7

Posted 24 November 2019 - 06:21 AM

Hi Ernie,

Well, the wire gauges are different, as are all the winds. Then too, the timing is set differently to accomodate the different winds. The real difficulty here is getting the spacing and clearance for these coms. With the com too close to the end bell bushing, the tabs will hit the underside of the brush tubes. With the com spaced further away from the bushing, the brushes will run off the top of the com. It's a very close call either way, and fidgety as heck to get it right.

- hiline2 likes this