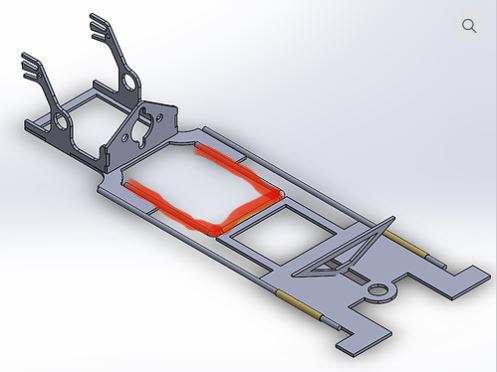

So I decided on the ESR1 chassis as my next build. The guy who owns the shop is a big fan of it, and it looks like a great chassis from what he's shown me. It's fast, consistent, and durable.

He gave me a rundown of how to put it together but that was a month or two before the whole COVID mess. Now that I've got a slight break from classes and summer break on the way, I want to start building it and don't remember too much of what he said. I would go in person, but not sure I can do that with quarantine.

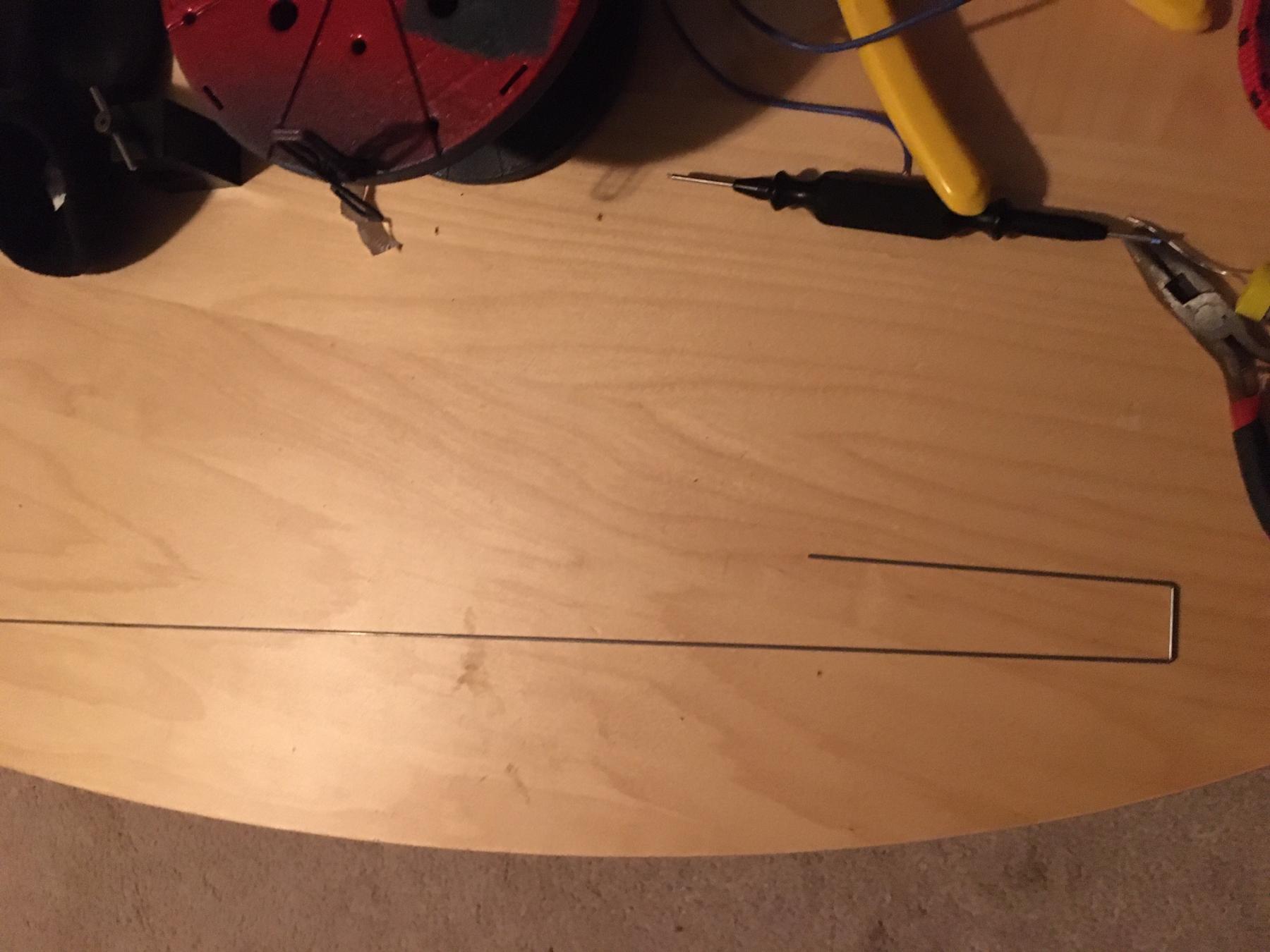

How exactly should I put this together? Thankfully I've got a great foundation to start on courtesy of the shop owner. I bought all the wire I'd need and he bent it for me, forming what looks like part of the center chassis. Specifically the wire and tubing holding the front plate to the rear (picture included). I also plan on building it with a wheelie bar.

Any pictures would be greatly appreciated. Hope you can help.