Maybe I'd be better off buying a Hudy, but I need a stay-at-home project. So what do y'all think?

Posted 25 April 2020 - 04:57 AM

Posted 25 April 2020 - 08:36 AM

No reason it can't. Not sure about the accuracy of the cross-slide handle. It appears to be a ratchet wrench.

Posted 25 April 2020 - 05:49 PM

Of course it can.

Please show us progress photographs.

Haha! ![]()

No reason it can't. Not sure about the accuracy of the cross-slide handle. It appears to be a ratchet wrench.

Good catch! Curiously, it's looks too modern for that era. Also it looks like a "pass through" ratchet, or whatever they're called.

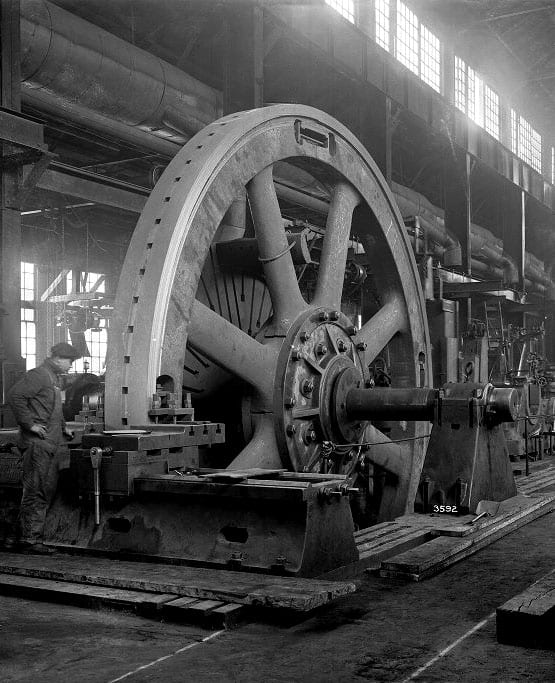

I wouldn't get anywhere near that if it were spinning at 2000 rpms! (do tha' math!...figure that od is about 15 feet across). Although the sound would be awesome.

I would guess closer to 20 feet. If correct, that's 12,566 SFM. ![]() That might be a bit hard on the cutting tool.

That might be a bit hard on the cutting tool.

http://www.carbidede...las-turning.htm

Posted 01 May 2020 - 12:50 PM

After WWII these triple expansion steam engines were surplus and a dime a dozen. I bought one to power my little machine shop.

Actually, it is an engine built to power the Liberty cargo ships that were built to carry war goods to England. The frame castings

were cast by my grandfather's (father's father) foundry in Chicago. It was one of only two foundries that had pour pits deep enough

to do it. The engines were erected in a building next to the casting buildings, then loaded on barges to be floated up Lake Michigan

to a shipyard in Milwaukee, Wis. But there actually was a surplus of these after the war. With factories changing to all electric, and

power plants changing to turbines, there were few uses for steam engines this large. It's nearly 30 feet from the foot casting to the

top once the cylinder heads are installed.