Since I grew up in the 60s, it is no surprise that the cars of that era are some of my favorites, especially the endurance machines. The struggle for supremacy during the 60s between Ford and Ferrari was the real story of LeMans contests in that era. GT40 Mk I, GT40 Mk II and Ferrari 330 P4 plastic models are readily available, albeit a bit pricey. Unfortunately the GT40 Mk IV is not available in 1/24 scale in plastic.

That was no deterrent. I purchased a couple of Mk IVs cast in resin over the internet (see images below). The resin models were beautifully detailed but extremely heavy at 91 grams; totally unsuitable for slot racing. I thought about hogging out the extra weight; however, I was concerned that the first hard crash would demolish the car.

I considered a couple of options. First was 3D scanning and printing. Second was molding and casting. After some research and discussions with others on the forum, I decided that 3D printing was out. The resulting printed model would require a huge amount of work to smooth ridges. Also, I would have to find some entity to do the work which would have been prohibitively expensive and a one off as well.

I began researching the option of molding and casting. I received some input from members of this forum and I discussed resin casting with a sister club in Eugene, Oregon that runs several classes of cars cast in resin (I have chosen not to name these folks for privacy reasons, but they are certainly welcome to comment). I also looked at many videos on the internet.. Check out the following video

https://www.youtube....h?v=WlTuDgzhTlk ).

Also check out this link which shows how to slosh cast.

https://www.youtube.com/watch?v=yAWgrwYq0iY

Finally, I determined that my first molds and casts would be completed using Alumilite products. I discussed my project with their technical support staff. They recommended that I use Alumilite HS2 for creating the mold and AlumiRes RC3 for casting (see images below). Their Technical support also put me in contact with a master resin modeler named Bob Hays whose scratch built masterpieces are truly works of art. Discussions with Bob were quite illuminating and interesting. After due consideration, I decided to make a one piece mold and slosh cast the model. This would minimize the cost of the mold making material. In addition, I would not have to thin the walls of the original model to create a thin walled (and therefore light) casting of the model. Since I used the Alumilite products, below is a link to the molding product I will use.

https://youtu.be/C5fdr9aFmro

Now that a plan was developed, I needed to know how much molding and casting material to buy and then create a cost estimate for the project. Since these materials are quite expensive, I did not want to purchase too much or worse yet, not enough to make a mold or cast a model.

Steps in calculating molding material are as follows

Determine the size of the mold box in cubic inches

o Determine the max length, width and height of the model

o Add a buffer around the model

Determine the actual volume of the cavity that the model would create

Calculate the weight (in pounds) of silicone needed

o Volume of mold = Volume of mold box volume of cavity of model

o Knowing that the silicone weighs 21.5997 grams/cubic inch, calculate pounds of silicone needed for the mold

Below is a table illustrating the volume of the mold box in cubic inches.

When the mold is created, the inside of the model will be filled with clay so as to create a cavity in the mold box which is the female representation of the model. For the sake of estimation, I wrapped the model in clear tape. A rectangular vessel was filled about half way with water. The height of the water was marked on the outside of the vessel. The taped model was submerged in the vessel and the new height of the water line was marked. The amount of water displaced by the model was removed, weighed and then the converted to cubic inches. This calculation is shown in the table below along with an image of the taped model

Knowing the volume of the mold box and cavity volume, the volume of silicone in cubic inches can be calculated. It is 74.25 22.143 or 52.107 cubic inches of silicone needed.

According to Alumilites website, there are 21.5997 cubic inches per pound of silicone. Therefore the pounds of silicone needed for the mold is 2.412 (or 52.107/21.5997)

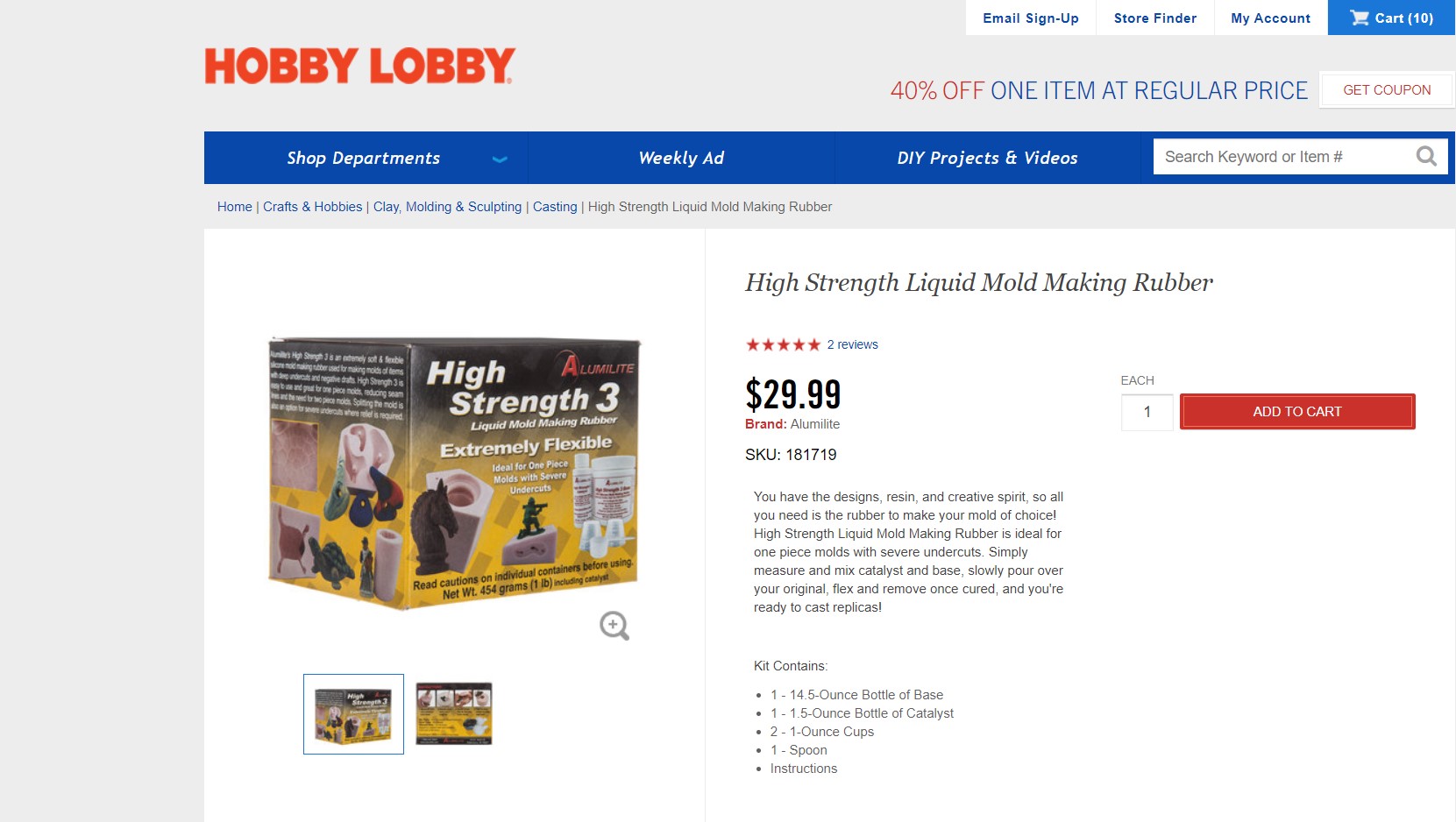

Below is an image of the molding material I will use (a screenshot from the Hobby Lobby website). Note that the HS3 shown below is one pound in net weight. Therefore I will need three to create a squish mold for this project.

Casting Resin Requirements

I will slosh cast the model and it will have thin walls to ensure lightness. Here, I will also use an Alumilite product called RC3. Notice that the product is two parts and each part is 16 fluid ounces. This should be enough for several castings.

Other Supplies

Mold Release agent (Purpose prevent resin from sticking to the mold) Note - after several replies to this post I have decided not to use mold release

Clay (Purpose to fill inside of the model before making the mold)

Misc. mold box material, receptacles for mixing, stir sticks, etc.

See images below for sample products

Next, I developed a ball park cost estimate. See table below

Dang, this is going to be an expensive project. Not only will I spend about $100 for materials, I also have incurred a sunk cost of the resin models I purchased on the internet (about $130), but what the heck. In these Covid times I really need projects to keep from going stir crazy. In addition, this is my first attempt a molding and casting and creates an opportunity to learn something new.

I will post as additional progress is made and I welcome comments.

Today (10/3/20) I had a chance to work on getting the model ready for molding. The model was filled with clay and I decided to add fender flairs in front. I looked at some early images of the MKIV and flairs were a part of the package. It did take a while to get used to forming the clay. I recently purchased some clay forming tools and just started fooling around with them as I worked. I improved over time and the next project should be easier. After preparing the model, it was mounted on some hardboard (I drilled and countersunk a hole in the bottom of the hardboard and used a countersunk wood screw to attach). Below are a couple of images of the car ready for molding

Matt D suggested a ledge under the body so there would be a clear demarcation between the underside of the body and waste material. I did this but it is hard to see. Below is Matt's image

The mold box is now complete. Note that I have sealed all edges of the box so that silicone will not seep out. I used caulking but some use clay or hot glue. See images below

Today (10/9/20) I poured the silicone mold. First the mold box was raised about a quarter of an inch at the rear of the car. I used three, one pound kits for the job. Each kit includes a plastic container of silicone and a plastic bottle of catalyst. First I mixed the silicone (by itself) to make sure there had been no separation of product (this is recommended). The catalyst bottle was then shaken, again to ensure that there had been no separation. I then poured the catalyst into the plastic vessel that contained the silicone (there was space at the top of the container for the catalyst). The silicone is white and the catalyst has a pink hue. I mixed the silicone and catalyst thoroughly so that there were no swirls. The mixture was poured into the mold box in the corner near the front end of the car being carful not to pour on the car but in the space between the front edge of the car and the box. This process was repeated for the second and third kits. The silicone was pushed uphill toward the rear of the car. The process is supposed to minimize potential for air bubbles to adhere to the car itself. The entire process took about 25 minutes well within the 45 "work time limit". See the image below for the workbench

Today (10/12/20) I removed the model from the mold and prepared the mold for slosh casting. First I deconstructed the mold box and pull the sides of the box away from the mold. It took a bit of force but not a great deal. Then I removed the model from the mold. I was surprised that it was so easy for two reasons. I did not use any mold release and also because the MKIV has a severe undercut in back and some in front. I then carefully cleaned the inside of the mold removing a few small bits of clay. I used a wooden popsicle stick and a paper towel moistened. Finally I cut the mold box so that when the mold was slipped back in the top was flush with the mold. I then reassembled the mold box and slipped the mold back in. Notice that I used hardboard on the edges of the top of the mold box. These will keep the mold in place as I slosh in all directions (sometimes even upside down). I am now ready to slosh cast.

Today 10/14/20 created the first slosh cast. Quite easy I would say. I mixed about 20 grams at a shot (10 part A and 10 part B) and poured it into the mold. sloshed for about 3 minutes when it began to set up. The did 3 more of the same amount mixes. The cast came out awesome! The detail was fantastic!!! Next time I will use less material. The first cast will need to be lightened by removing material from the inside of the cast. Below are some images. The second image shows my first cast versus the original model.

Today (10/20/20) I poured a second cast. This time I used much less material and used a dye in the casting mixture so it would be easier to tell where the casting mixture was laid down and where more was needed. I was happy with the result and the weight of the cast was about 34 grams before the windows were cut out, however, I did not leave the cast in long enough and when I removed it from the mold it twisted a bit. Upon further work I realized this cast was not going to work. Also, I did find that my custom front flares needed to be set higher so I used some JB weld epoxy and added some material. This will allow the front wheels to extend to outer edge of the flare. I will post an image when the model is ready for paint. One lesson I learned this time is that the dye is difficult to a consistent color from each of three pours needed to complete the cast.

Today (10/27/20) I poured cast number three. I allowed much more time for it to set (several hours) and it came out pretty good. The cast weighed only 29 grams before removing windows, and cutting wheel openings. There were a few thin spots that I will fill with JB weld from the inside. Belows is an image.

Today (11/1/20) the latest progress is in regard to painting. After several types of paint, I found this worked for me. First, I used the duplicolor primer shown in the center of the image below. I gave the car two light coats then one finish waiting 10 minutes between. Still there was a blemish on the top. I waited 30 minutes and wet sanded the blemish then re primed. Came out quite well. I waited 24 hours then used duplicolor perfect touch paint. I selected a red (can not shown). I gave it two dusting coats then a heavier coat. I did not yet like the coverage so I gave it another heavier coat. After each coat I waited ten minutes. I was happy with the coverage but the finish was dull. I waited 24 hours then used Future. The paint shined up nicely. Note that the paint comes out in larger droplets than model paint but don't worry. Take you time with any number of dusting coats. with ten minutes in between. The heavy coat will appear to come out "wavy" but as it dries, the surface tension of the paint will smooth it out. See images below

Today (11/11/20). I primed and painted body#2. I used the Rustoleum Lacquer black paint show in one of the images above. The paint went on nicely, however, It highlighted the flaws in the casting which look like several pin holes. Chalk that up to experience. I also primed body#3 (see model in gray primer below). I will attempt to fill in flaws with the Tamiya putty shown below

11/17/20. Today I cut the #3 body front wheel wells to the proper wheelbase. Tedious because of the small amount of clearance. Image is shown below. I still have some work to do with the flairs (they need to be extended)

11/18/20. Body #2 finished in fantasy livery.