Whenever I visit a track, I like to buy my tires there as a way to give them some additional support. And most tracks generally have a good selection of .790 and .812 tires so this usually works out just fine. Unfortunately, vintage Thingies have very odd tire sizes that aren’t readily available. So for a Dynamic Renegade that I am currently resurrecting, I wanted to try some silicone tires to get around this issue. And luckily H&R makes some lovely 27mm silicone wheels & tires that in theory would be great for a Renegade. So I ordered a pair and while the tires are indeed a good size match, the wheels don’t have threaded hubs and worse yet, the collar where the set screw resides is exactly where the threaded 43T spur gear needs to be. Simultaneously, I was able to procure a 42T threaded aluminum spur gear but all I could find in the needed 43T size was a vintage Cox spur which again had a collar with a set screw which means the wheels would be pushed out way to far to clear the collars for both the wheel and spur gear.

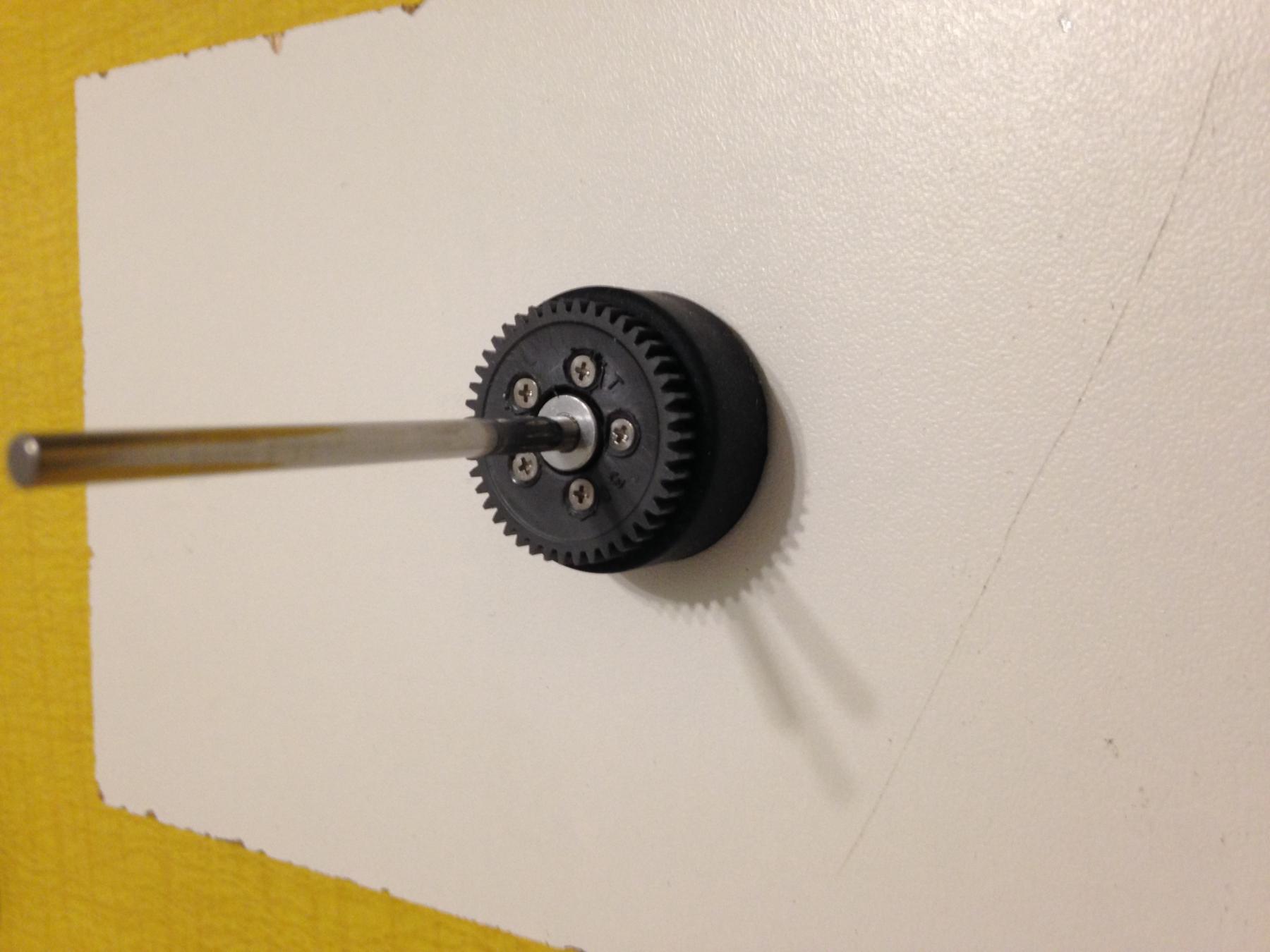

Enter plan B. The slots in the H&R wheels are very uniform, clearly CNC machined. So I 3D printed an adapter plate that basically is a plastic disc (1.5mm thick) with 5 small protruding rods that snap into the H&R wheel slots to center it. There are also 1.6mm holes drilled thru the rods and the underlying plate. Lastly the adapter plate has a hole in the middle that is the exact size as the collar on the cox spur gear. Below are some shots of the plate and then the plate slid onto the collar of the Cox spur gear.