Has anybody here some experience with this type of chassis?

After purchasing two C30 F1/Indy chassis, Tim Homola (JK Products) suggested me to join in this Slotblog forum.

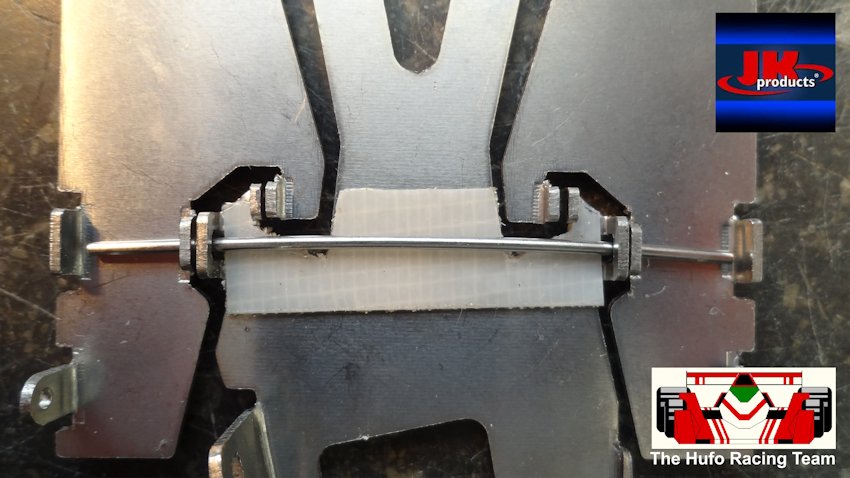

I've been "outlining" both chassis on my techblock, and I‘ve noticed the following:

Holding the chassis in my hand in a horizontally position, the rear of the one-piece pan “hangs” lower than the centerpart (approx. 0,5 mm) Is this normal?

As a retired national and international slot racer (and returned to my attick) racing in 1/24 Eurosports and X12 classes, I’m used to ground clearances of 1 mm (and up to 1.5 mm here at home on my Carrera track). So for me it’s a normal thing all (rear) chassisparts have the same groundclearance.

I’ve a solution in mind, but is it a good idea:

Once the chassis is laying on the tech block, should I solder the cross bar onto the pan (at both sides), while that same cross bar is laying flat on the centerpart?

That way the pan can still move in all directions, after all, it's a one-piece pan.

When I mentioned this idea to Tim, he answered: "most people leave the cross bar loose to maximize compliance of the chassis."

So now, I'm wondering if I'll do well with soldering.

Greetings from Belgium,

Hubert