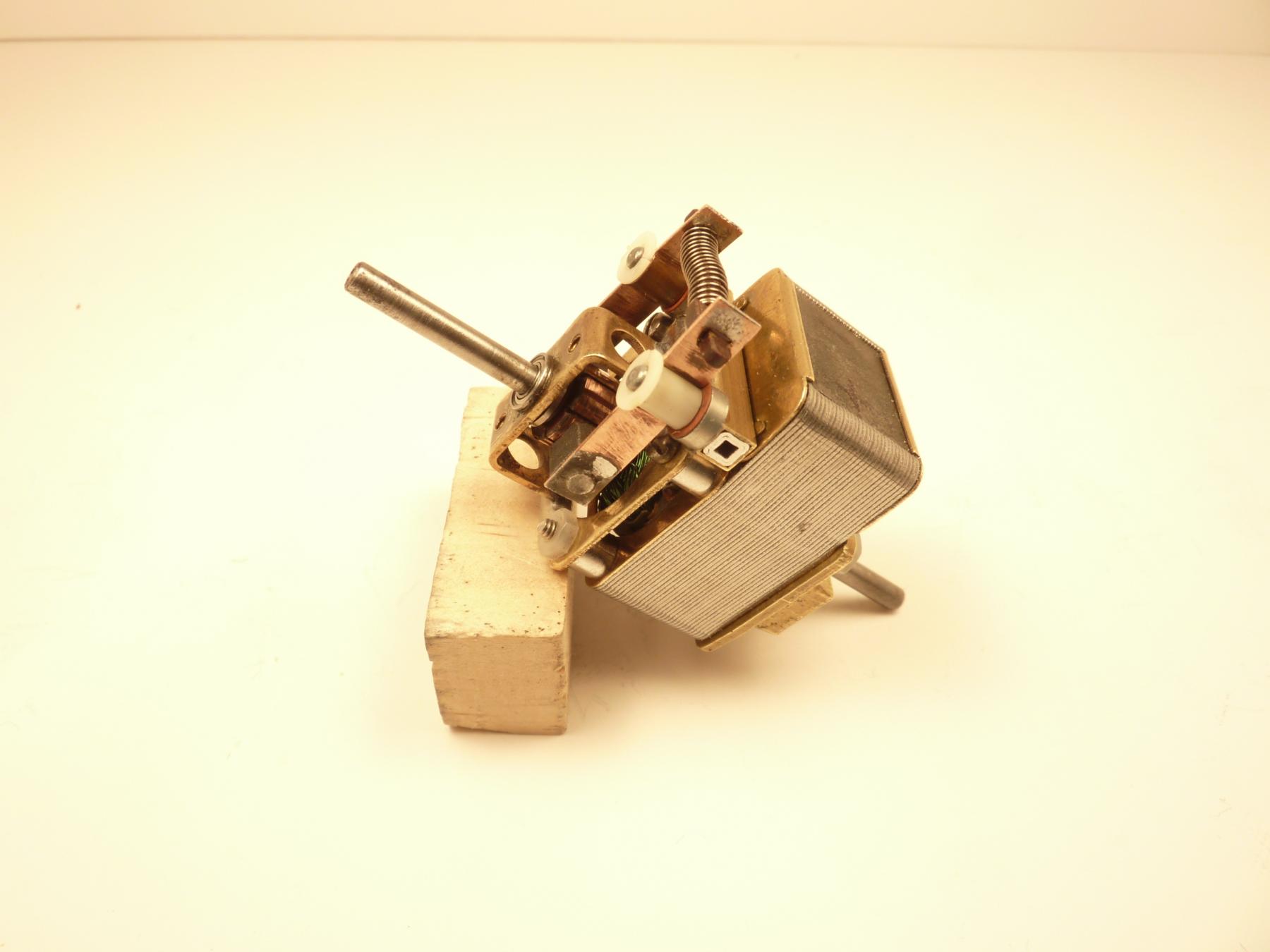

I had put time into completely machining the end plates before doing a test fit of the components and didn't want to ditch them. I tried some work-around's like grinding the inside of the hole in the field laminations, but soon gave up because that's an absurd way to build motors.

I prepared another pair of endplates, shifting the 4-hole through-bolt pattern of the 12 volt Kemtron motor's field laminations on the Pittman endplates to center the armature. I did not machine the endplates to their final form, just drilled a new four-hole pattern.

The revised endplates with the re-positioned hole pattern also did not work with the Kemtron 12 volt motor's field laminations. It was still a tight fit.

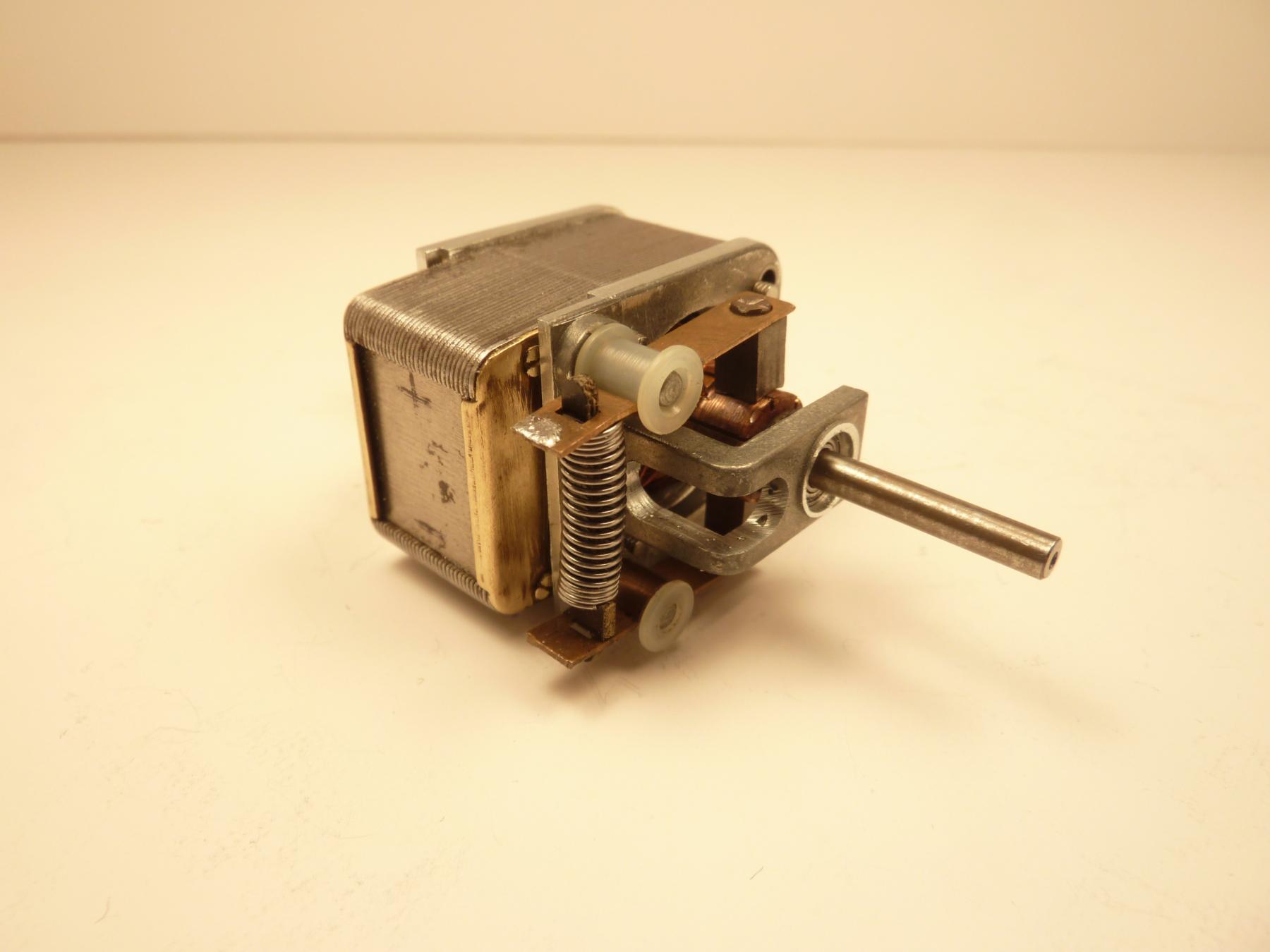

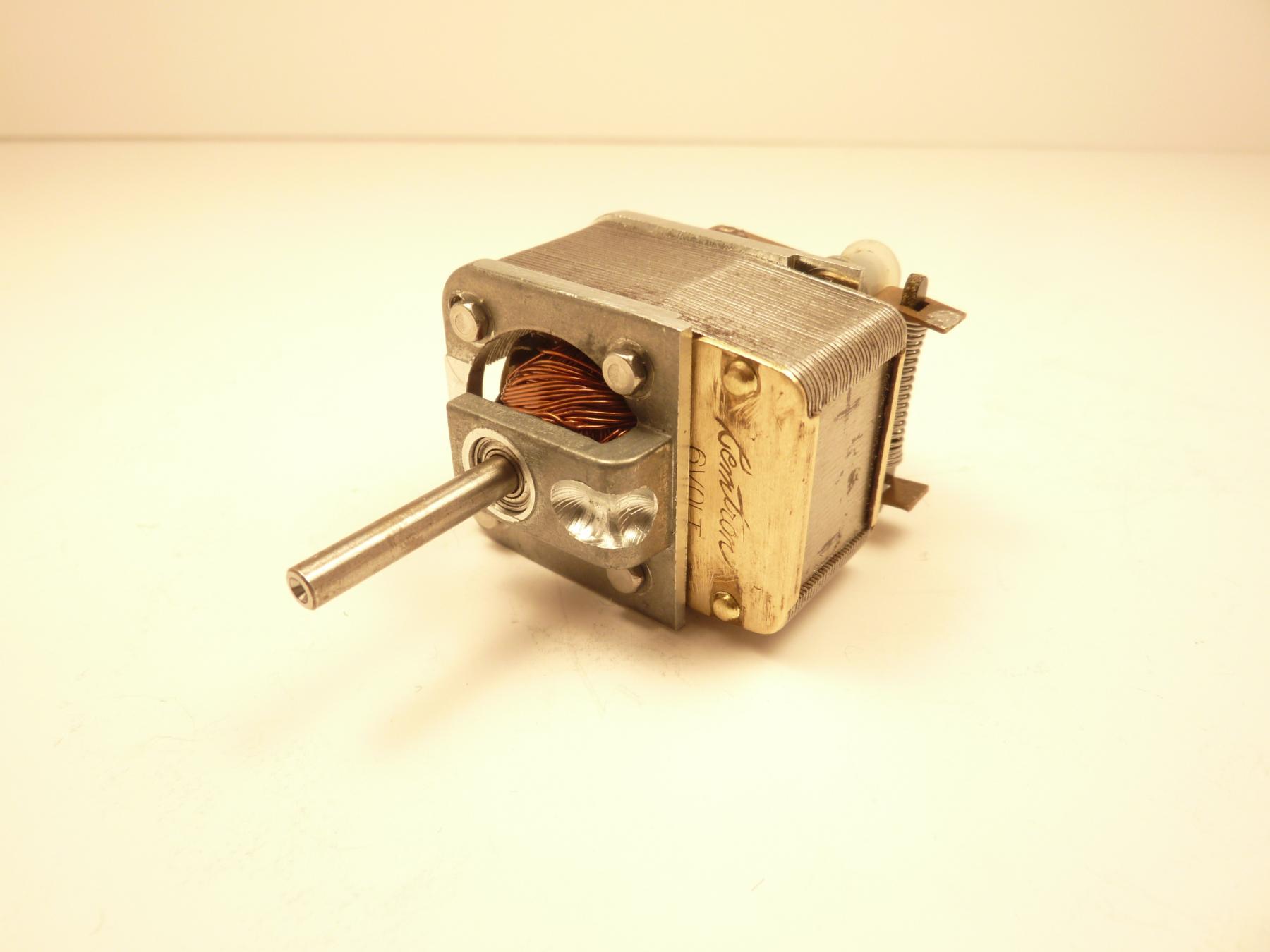

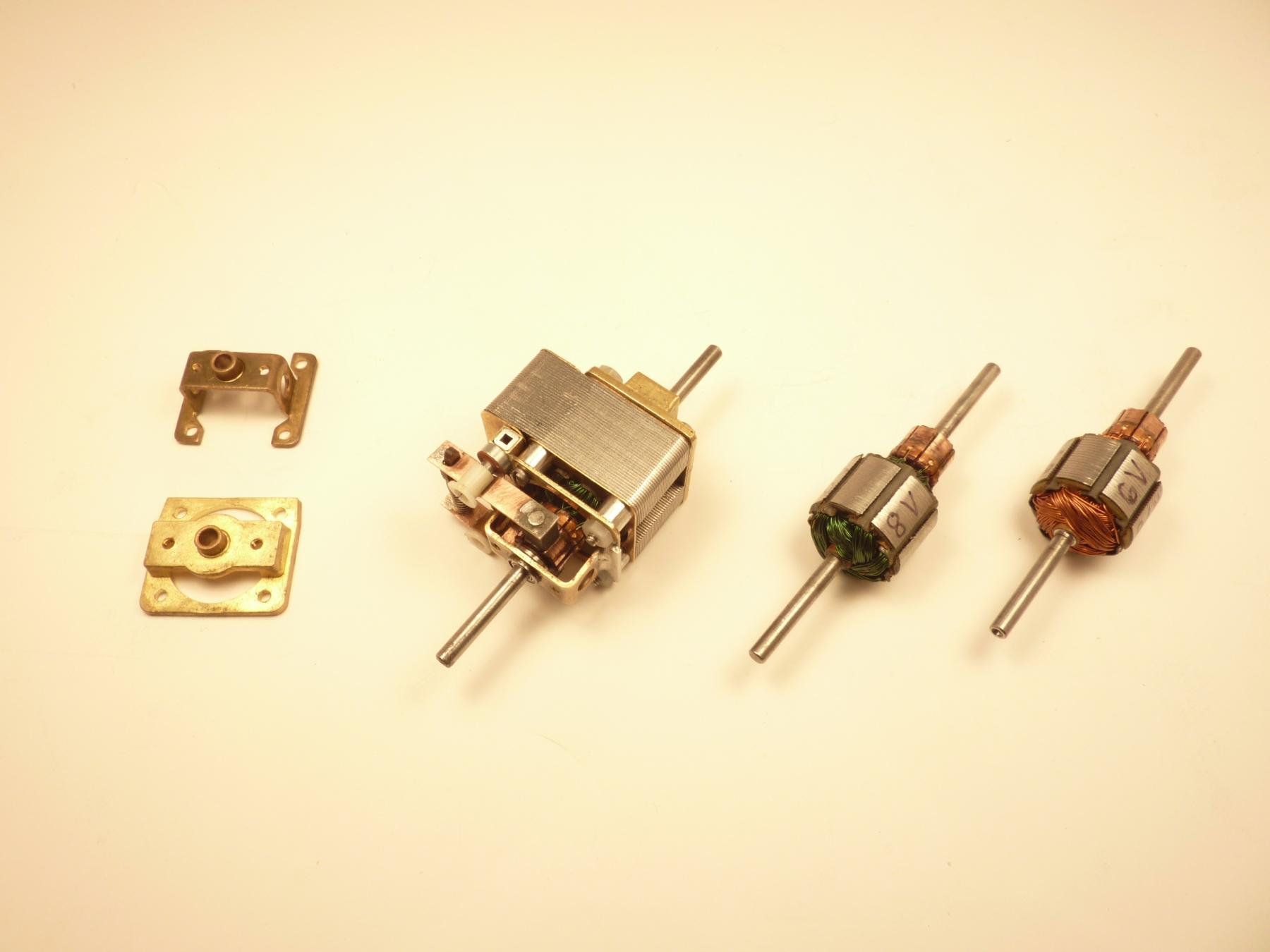

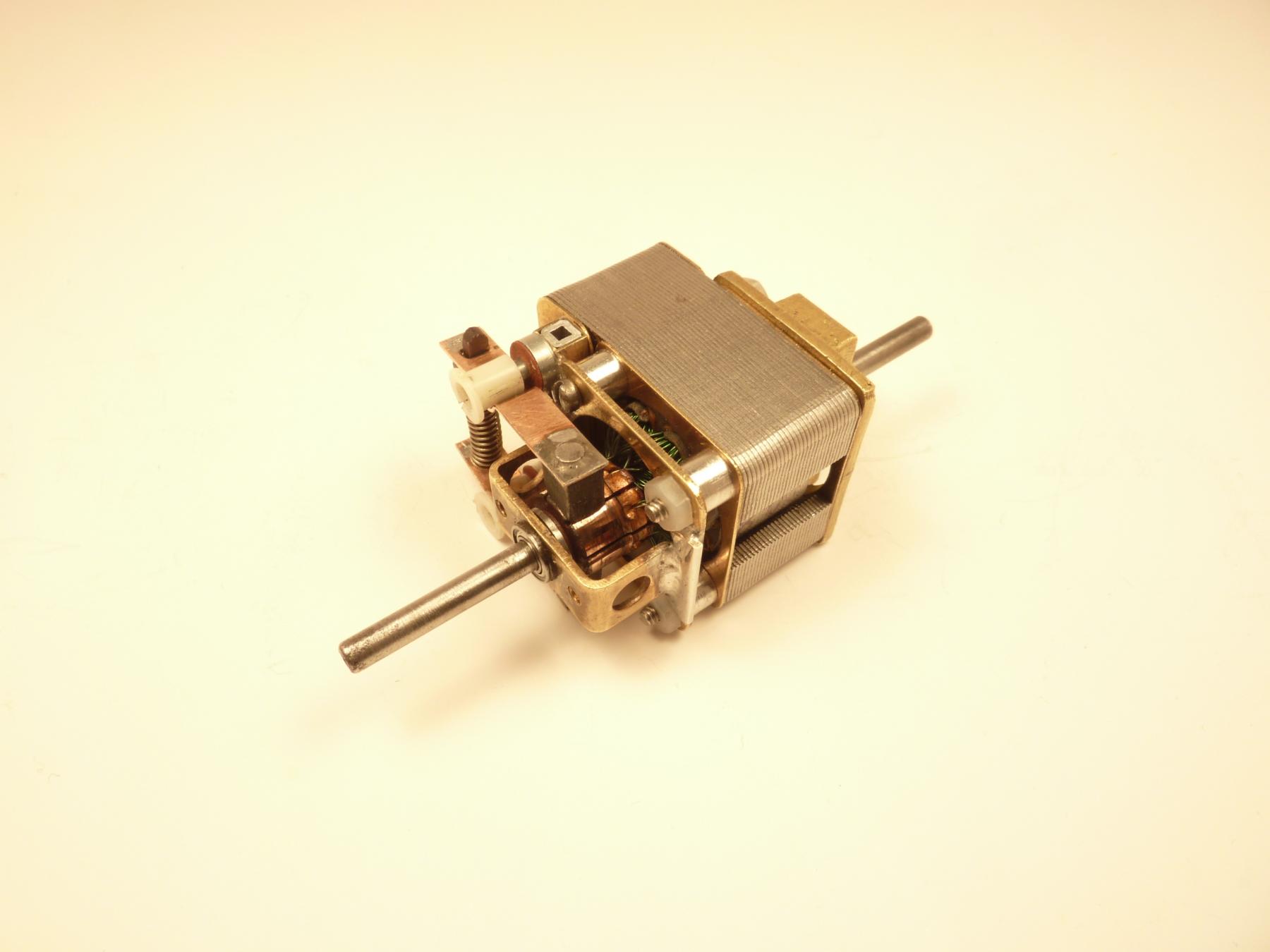

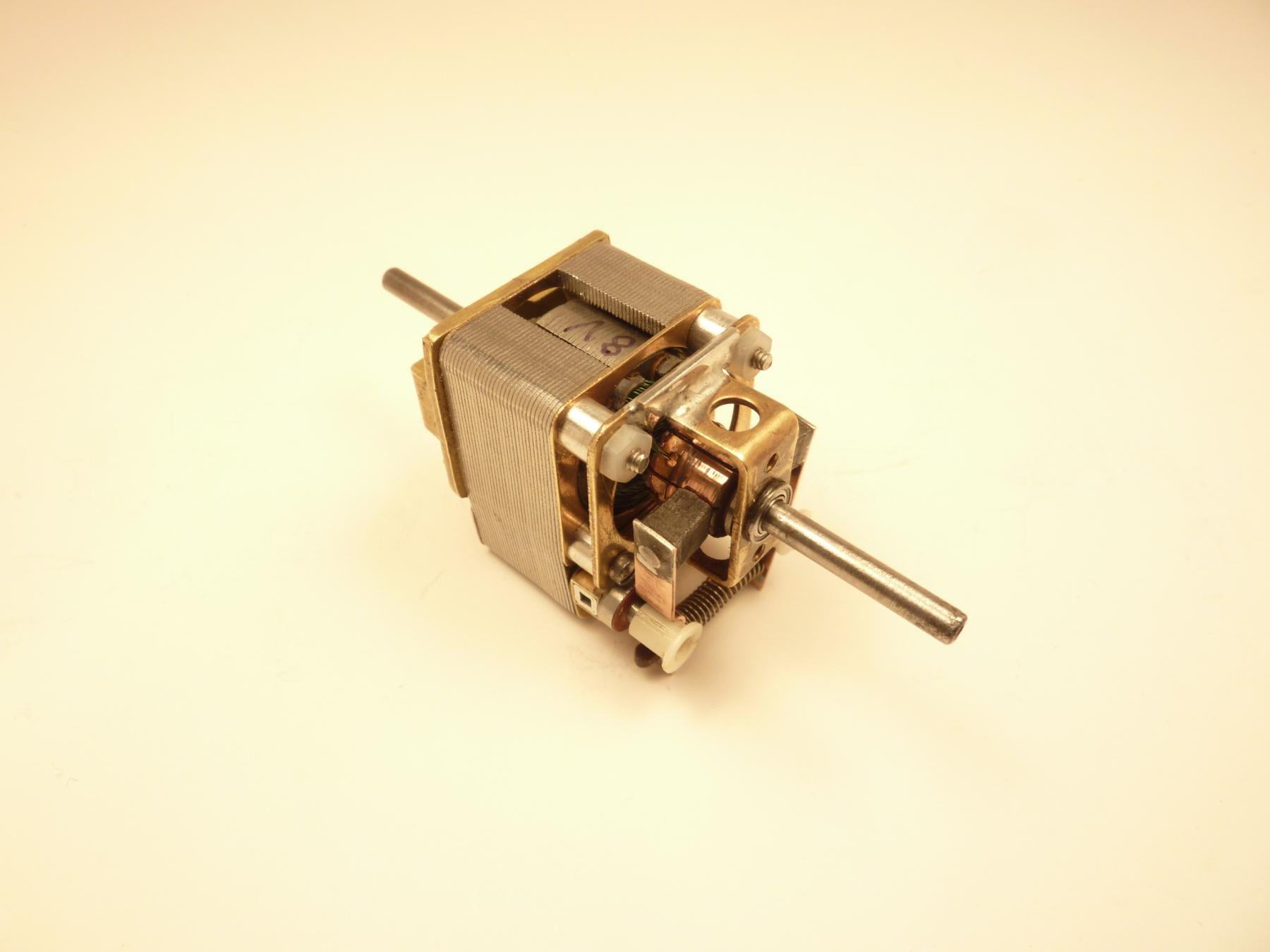

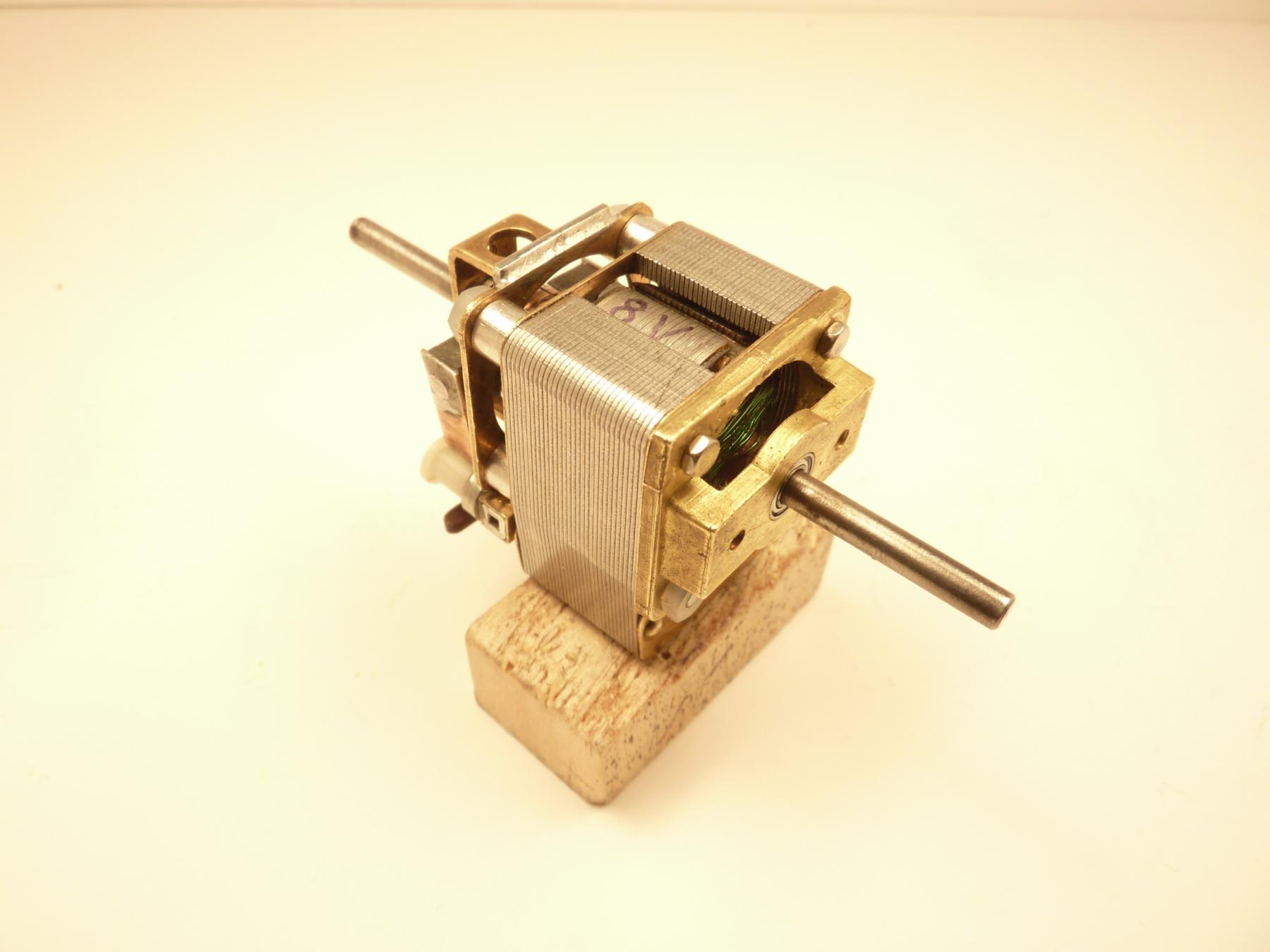

I took another tack, switching from the Kemtron 12 volt motor to Kemtron's Mustang motor.

I discovered that the Mustang motor's 8 volt armature is identical to the Ram 6 volt arm other than voltage rating. Kemtron's product bulletin for their Mustang and Bronco motors says that the armatures in both motors are, in fact, made by Ram.

The armature hole diameter in the Mustang motor's field laminations appeared to be slightly larger than the Kemtron 12 volt motor's hole diameter.