Hello, team,

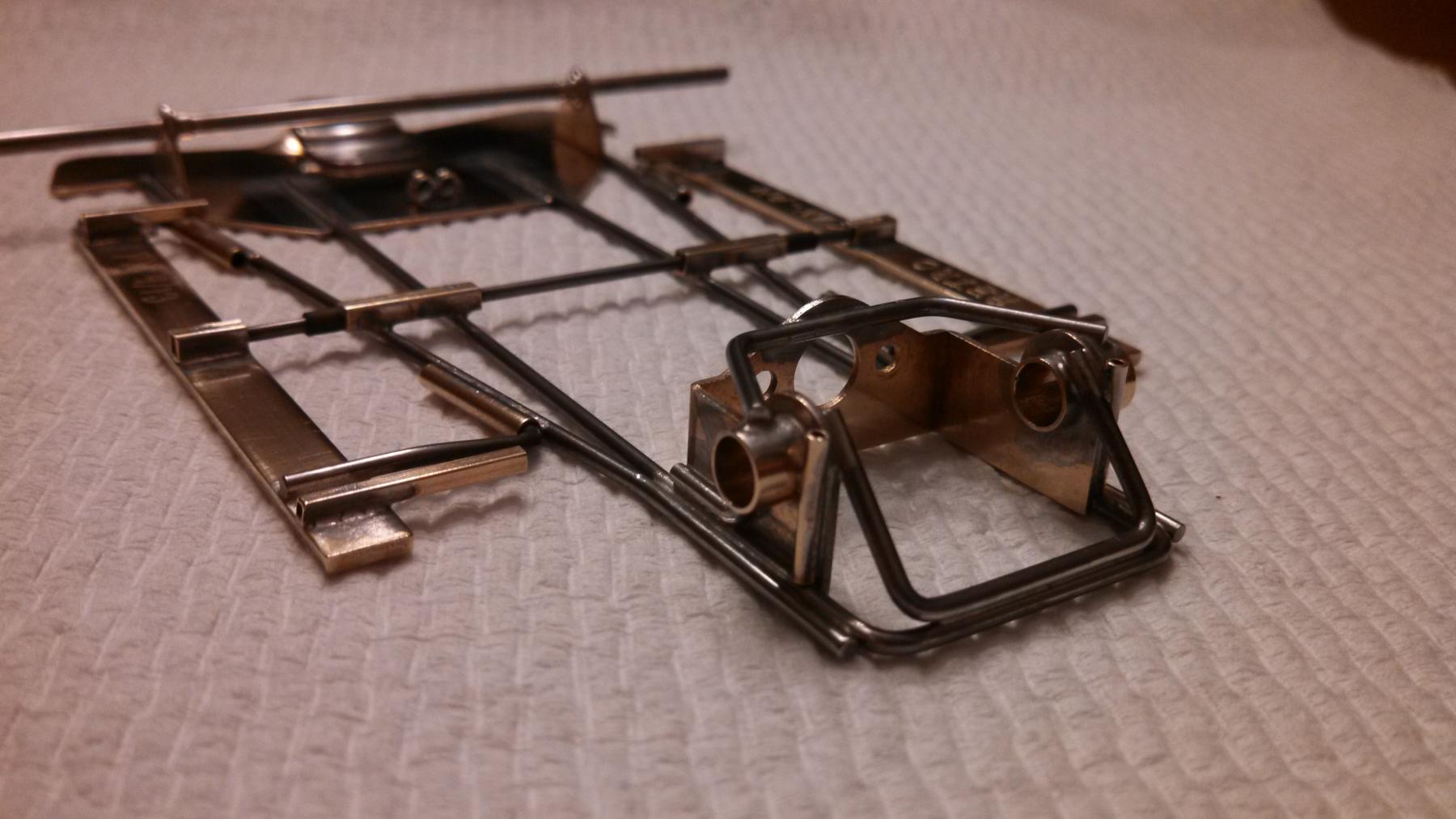

It's is my first attempt to build an IRRA Stock Car chassis. Can you please point my mistakes, and show me I can improve my skills.

Thank you.

Posted 13 April 2021 - 11:10 AM

Mike Katz

Scratchbuilts forever!!

Posted 13 April 2021 - 11:18 AM

A little less solder would keep it cleaner. Use lot's of acid flux-- just enough solder to spread after the heat is applied. Then keep cleaning after soldering. Nice job--- looks good!

Posted 13 April 2021 - 11:44 AM

A motor is only as fast as the chassis it's in.

Dominic Luongo

Like Dominator Custom Chassis on Facebook

NERR photos from 2012-April 2016

NERR photos from 2016 to now

Posted 13 April 2021 - 12:06 PM

Excellent work for the first time, great job! ![]()

Paul Wolcott

Posted 13 April 2021 - 06:37 PM

It looks like there were not any axle tubes originally and then you added them? Did you start with a long tube going across and then cut it? You have to cut the tubes almost flush with the inside of the bracket. Here you can see some bracing..

Mike Katz

Scratchbuilts forever!!

Posted 13 April 2021 - 07:06 PM

Posted 18 April 2021 - 03:42 PM

Chris Wendel

Silver Side Down Racing

Silver Side Down Graphics

The Race Place Retro Crew member

"Failure teaches way more than success. It shows what does not work and what to never do again, again..." 🙊🙈🙉

Posted 12 June 2021 - 03:30 PM