I wanted a track that I could easily put away when not in use, so I decided to try my hand at building a folding track and hoping to keep it lightweight?!

I started it the later part of 2020, after I posted my initial experience with finding a router guide strip.

I was working as efficiently as I knew how, hoping to get the track at least primered before the cold weather set in.

I did get it in primer, but unfortunately the winter cold temperature set in.

I made an attempt to heat up the garage as well as getting enough airflow to draw out the solvents of the primer.

I used automotive 2K primer surfacer because I had some leftover from a project car.

I'm at a standstill at this time, because there are a few primer cracks caused by solvent being trapped and finally gassing out.

The reason I'm at a standstill is I'm undecided if I want to continue with it, or sell it as is.

I just assembled it as it sits at this time; it seems close to being done (after the primer cracks are addressed), with only final block sanding of the other half, painting the track, laying down the copper tape and wiring it up/

Here are photos, of my very first attempt at building my own home test track.

Starting out with 2 pieces of 1/2" thick birch plywood cut to 3 ft x 6-1/2 ft sizes.

Footprint is 3 ft x 13 ft with a 12 ft long straightaway.

Uncut weight of 55 lbs.

Placed the 2 sheets together and started to layout the guide for the router.

The router guide was screwed into place.

I used 1/2" PEX tubing to aid with the curves.

I made an rod coupler from a dowel to butt the ends together.

Aligned and butted together.

Router guide layout completed.

Starting to route slot.

Finished first slot.

I fabricated a jig for the second slot from aluminum composite with the addition of nylon glide strips.

Starting to route the second slot.

Second slot complete.

I cut out areas in an attempt to lighten the weight.

Got the weight of both boards to 40 lbs.

Removed router guides and filled screw holes by gluing in wooden hole plugs I made from a dowel.

Then flush cut them and sanded flat.

Had a good size piece fracture that come off which was repaired.

I then guide coated the boards, filled some minor flaws and started to blocksand.

I felt a bunch of waves which is why I decided to blocksand the surface prior to applying the primer surfacer.

Finished blocksanding and ready for primer surfacer.

Primered and guidecoated.

Finished blocksanding one side and then had to wait for a few months for warmer weather.

I thought all was going well, but upon recent inspection I discovered a few areas that had cracks in the primer.

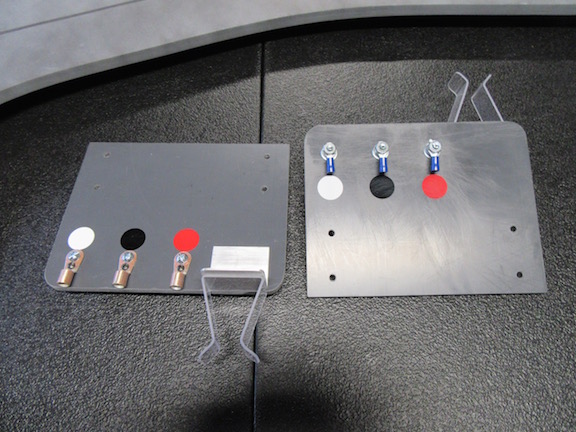

For the controller stations, I used strips of polycarbonate, which I bent to shape, as well as employing terminal ends for 10 awg wire, screwed onto 1/4" thick PVC board for the controller alligator clips.

Protective covering removed and then mounted onto the PVC Board.

Controller Tested for fitment.

Controller Panel - top and bottom photo.

Track assembled with Controller Stations Mounted.

Thank you for looking.

Ernie