Desodering motor out of JK21 chassis

#1

Posted 21 November 2021 - 01:35 PM

#2

Posted 21 November 2021 - 01:47 PM

Hotter iron, lots of acid flux. Once the joint is wet, shove an Xacto blade between the chassis and the motor

Paul Wolcott

#3

Posted 21 November 2021 - 01:49 PM

Get a hotter iron, the Hakko's with the adjustable heat knob are great. PCH has them. The X-acto blade like Pablo said also works great.

#4

Posted 21 November 2021 - 02:59 PM

An alternative method, is the "flick" method. Have a waste paper basket/paper bag, right next to you. Heat the bottom solder joint, first. When the solder gets hot, simply flick the chassis, into the waste basket. If your iron is hot enough, the top joint should be void of solder. Then, proceed to the motor mount joint. Afterwards, reheat both joints, to remove any remaining solder. That's the way, I've always removed motors.

Al ..

- Tim Neja and bbr like this

Al Pollack

#5

Posted 21 November 2021 - 03:59 PM

I use a solder sucker like this to remove the solder- https://www.amazon.c...N5C4,B011OXM496

Start with the plunger pressed, heat the joint, hold the solder sucker next to the melted solder, and push the button. It will quickly and easily get rid of the hot, melted solder.

Then, once you've removed a lot of the solder, work something like an Xacto blade into the joint, like Pablo suggested.

#6

Posted 21 November 2021 - 04:02 PM

"Flick it" like my friend Al said. This is my method on my PCB to clear out a component soldered hole on a PCB. A quick tap against your work table works best after heating up the solder joint hole.

Hey Al, when are you going to retire?

- SpeedyNH likes this

Jim Difalco

Difalco Design

3075 NE Loquat Lane

Jensen Beach, FL 34957

(772) 334-1987

askjim@difalcoonline.com

#7

Posted 21 November 2021 - 04:02 PM

A single-edge razor blade or a double-edged blade with one edge heavily taped (adhesive tape) will also work. Both have larger surface areas than most X-acto blades.

- SpeedyNH likes this

I intend to live forever! So far, so good.

#8

Posted 21 November 2021 - 04:06 PM

Heat the top joint then slide a single edge razor blade through to clear the joint, then heat the joint at the chassis. A small amount of of thumb pressure on the motor will break it free.

When I solder the motor in I gusset the joint at the front (or rear) with a small piece of brass or wire. The gusset is soldered to the frame, and then to the motor. When it's time to remove the motor I heat the joint at the frame and the gusset comes out with the motor.

In terms of your iron remember it's not just watts the tip needs to be a large area.

Edited by old & gray, 21 November 2021 - 05:20 PM.

- Bill from NH and Alan Dodson like this

#9

Posted 21 November 2021 - 07:31 PM

Glancing at these posts, I think at least a few of the posters aren't familiar with a JK C21 chassis.

They have a plate below the motor.

IOW, it's soldered on top of it.

It's basically a giant heat sink.

Depending on how well the motor is soldered in, it is difficult to remove.

If solder is wicked in, in between the bottom of the motor and the top of the chassis plate, I don't think you are going to flick or suck out that solder.

You need plenty of heat.

A 1000 degree + iron like a Hakko 601 or a $75+ Ungar/Weller is usually needed.

If the motor is history, I just flux that bottom plate, underneath it(the motor), and flood it with solder to provide maximum heat transfer from the iron.

From there, the motor will either fall out, or it will be easy to quickly get at the other joint and knock it out.

I then flick off that solder like described by others.

I have a large diameter wire brush mounted in a Bosch variable speed trim router, which I use to finish the solder clean up.

- Pablo and Matt Sheldon like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#10

Posted 21 November 2021 - 09:23 PM

What's wrong with Solder Wick?

- mreibman and RRM like this

#11

Posted 21 November 2021 - 09:26 PM

#12

Posted 21 November 2021 - 09:28 PM

Nothing i guess never tried it..it looks like braid

Yep. Sure does.

But it is impregnated with something that sucks up the molten solder when you apply direct heat to it.

Works a treat ![]()

#13

Posted 21 November 2021 - 09:35 PM

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

#14

Posted 21 November 2021 - 10:17 PM

No, it won't.

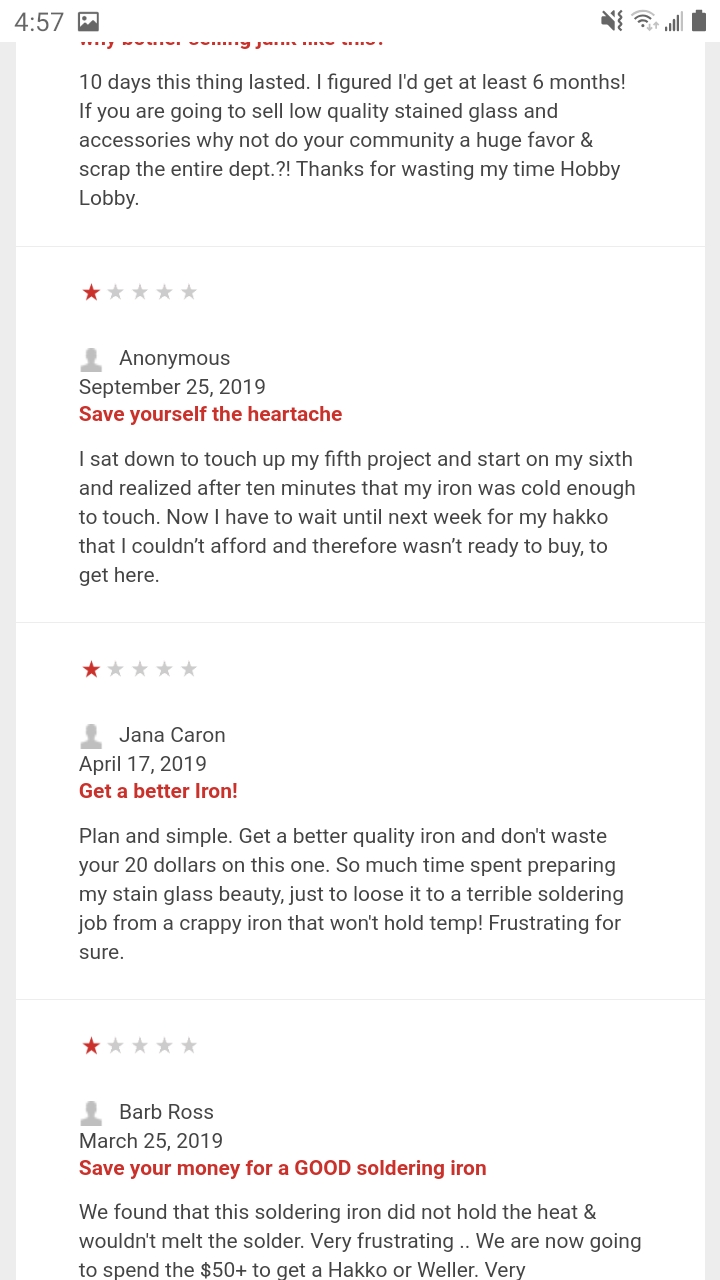

I saw that iron at the local Hobby Lobby and got excited, thinking it was an econo Inland,(100 watt, 1,100 degrees)like I use to sell when Eagle was distributing them.

Then I read the fine print.

734 degrees....that's awful.

And look at the crappy reviews.

Poor heat recovery.

Back to "desoldering" .

Despite the title in the thread, the OP is not looking to desolder.

He's looking to remove a motor.

Wicking out solder first, with that style of chassis is just going to make it harder.

You need solder for heat transfer.

- SpeedyNH and Alan Dodson like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#15

Posted 21 November 2021 - 10:39 PM

Not one positive review listed among those published. When I & my kids raced flexis with closed motor boxes, I always found if I was careful how I installed the motors, when I had to remove them, I had no problems. These were Parma & Champion chassis & I used a 25 yr. old 50 W Ungar iron for installing & removing motors. I got torches, a 80W Weller, & a 100 W Inland if I ever need more heat. The now 45 yr. old Ungars remain to be my iron of choice.

- nicky 65 and mreibman like this

I intend to live forever! So far, so good.

#16

Posted 21 November 2021 - 10:47 PM

#17

Posted 22 November 2021 - 06:01 AM

- Zippity likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#18

Posted 22 November 2021 - 10:48 AM

Once you get it out do not put the new one in like that.

Clean the solder off the chassis as well as you can. Set the new motor in the chassis with proper gear mesh and tack solder the motor to the top of the chassis bracket. Then use a short lengths of brass tubing as a gusset near the other end of the motor. solder the tube to the chassis and to the motor, It is quick to install or remove. then solder just the top edge of the motor to the bracket of the chassis. Easy in and out.

You can use a gusset on both sides of the motor if you want but I don't find it necessary.

I can take some photos if you want.

- Tim Neja, old & gray and swodem like this

#19

Posted 22 November 2021 - 11:19 AM

There's a lot of good info here....

- hot iron

- Solder wick

- xacto blade

- Flick

I personally wouldn't add more flux to the mix. I might (sometimes) actually add a little fresh solder on the soldering iron tip - especially if the solder holding the motor in is no longer shiny. I find that's helpful.

You want to remove solder - the wick is easy. You can use a braid to do it, but the chemical they treat the wick with is rosin flux. It makes the solder draw up into the wick. That stuff is great.

Remove whatever you can remove, get the motor rocking back and forth a little, and get the blade in to break the solder joint.... Go slow, and don't be holding the chassis with your bare hands when you do it. You don't want more of a heatsink, and besides your fingers are not good heatsinks. They burn at a lower temperature.

Hot solder will come off with a tap. You can tap the chassis on the bench if you don't mind solder flying out.

BE CAREFUL. Protect your hands and eyes! They're worth more than any slot car.

Alleged amateur racer.

Mostly just play with lots of cars.

Able to maintain slot cars with a single bound.

Faster than a speeding Womp.

More powerful than a 36D.

#21

Posted 22 November 2021 - 01:08 PM

- bbr likes this

#22

Posted 22 November 2021 - 01:29 PM

You're right, David. While my favorites are Ungar and Weller, I've had good luck with some cheap knock offs. A hot enough, and big enough, iron for the job is what a guy needs. Technique is important ,too.

#23

Posted 23 November 2021 - 02:39 AM

The one I have I pretty much use just for motor removal. I bought it at Hobby Lobby. I better make sure it is the same model. It will melt your whole car down if you are not careful. AJ watched me accidentally dismantle the rear of a retro Can Am car with it. Part are parts until they are apart.

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

#24

Posted 21 August 2023 - 07:46 PM

#25

Posted 21 August 2023 - 09:02 PM

Slot Kraft makes a bent "prybar" screwdriver that you can use as a lever under the motor after you get the first joint hot enough.

It looks sort of like this but not exactly:

Don't ask me where to get one because I got the one I use as a race prize.

This cheap tool can make your life easier if you build or race flexi cars.

Typically I only solder the "can" end and the back brace, It can be challenging getting the motor out if it's soldered in three places.