Comm lathe tips

#1

Posted 15 December 2021 - 08:45 AM

Should I use cutting fluid? Sounds like it might cause more trouble than good.

Should I use 2 O-rings around the armature or just one? Does it matter?

What voltage should I use?

Some general tips would be good too. I have had very little experience with these.

Thanks

#2

Posted 15 December 2021 - 09:23 AM

- FrancoD likes this

Alleged amateur racer.

Mostly just play with lots of cars.

Able to maintain slot cars with a single bound.

Faster than a speeding Womp.

More powerful than a 36D.

#3

Posted 15 December 2021 - 09:42 AM

There's a bit of a learning curve when dealing with comm lathes but once you've cut a few it's easy. A good idea is to start with a few old arms that you don't mind messing up.

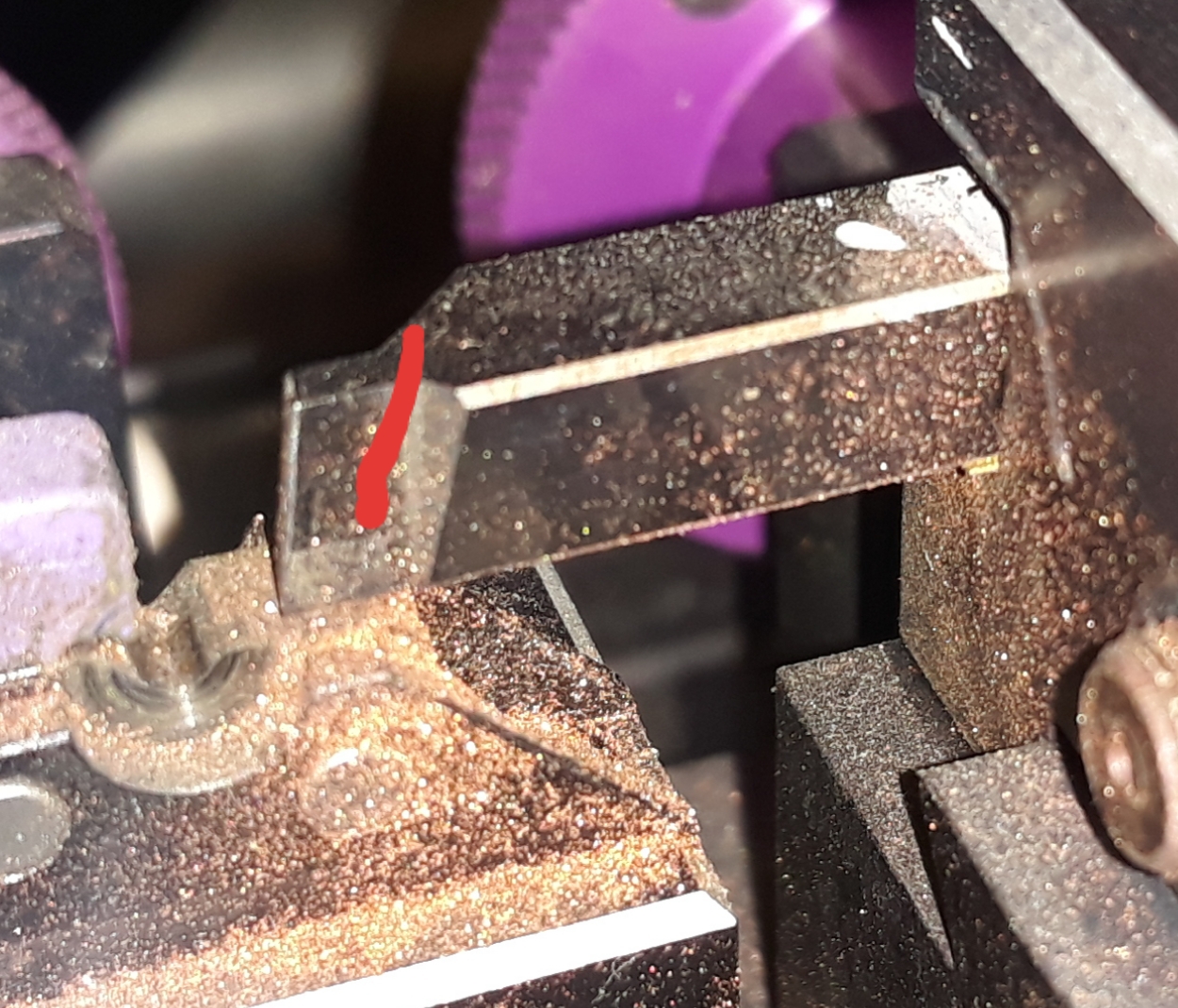

One of the most important things is to have the tip of the cutting tool (hopefully it has a diamond insert) set in the correct position, which is just barely below the horizontal center with the comm turning into the top cutting edge of the tool.

You will only need one o-ring and it shouldn't be too tight as that can actually bend the arm shaft and distort the cut. Another important point when setting up the arm is to have it spaced between the v-blocks so there is very little side to side end play. I usually add a tiny bit of oil (most any will do) but it's not absolutely necessary however it does seem to give a slightly better finish.

Set your power supply to 3-4 volts, back the cutting tool off so that it is close but NOT touching the comm and then move it away toward the end. Now slowly wind the cutting tool toward the comm and see if it is touching, which it shouldn't be at this point. Move it away from the comm and turn the dial to move the tool into the comm, this should only be a few divisions on the wheel and then move it across toward the comm. What you are looking for, especially on the first cut, is just a super light touch so you know where you are starting your cut. You may need to do this step several times to get the first touch on the comm but it's better than just running into the comm with way to heavy of a cut. Once you get the first "touch" move the tool across away from the comm and wind the tool inwards a division or two and run the tool across the comm. The big thing here is to NOT under any circumstance run the tool into the wire connections as this will almost certainly ruin the tool and/or the arm. Now perform the same in/out back and forth operation as above until the comm is completely cleaned up.

After doing this a time or two it will become almost second nature. One note here, if the comm has a rough texture to it your cutting tool may either be set up incorrectly or it will most likely need to be sharpened or replaced.

Good luck, have fun and I hope this helps!

- Cheater, triggerman and Half Fast like this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#4

Posted 15 December 2021 - 10:17 AM

#5

Posted 15 December 2021 - 10:24 AM

- swodem likes this

#6

Posted 15 December 2021 - 12:21 PM

I have a Cobrs comm lathe too. Some use an oil, some cut dry (the chips may fly dry). I use a comm cutting fluid Cobra sold, by no means is it the only thing that works. Black Sharpies can also provide cutting lubrication. I would think that lathe cutting fluids, such as Brass Tap, would work too, but I haven't actually tried it.

I intend to live forever! So far, so good.

#7

Posted 16 December 2021 - 01:26 AM

I have looked for comm cutter bits and the variety of available specs is beyond confusing.

Can someone tell me the proper specs for Cobra Pro lathe bits and a good place to buy them?

#8

Posted 16 December 2021 - 09:07 AM

James. I use a 1/4"x1/4" diamond bit sold by Cobra I don't know if Cobra is still in business. I was also given three no-name (maybe Chinese?) 1/4" diamond bits for my mini lathe. All three are ground differently than the Cobra bit. but two of them cut comms fine too. I question if there is a particular bit for the Cobra lathe, other than 1/4". Numerous slot car companies have sold comm cutting bits.in the past, maybe some still do. If I was looking for a new bit, I'd contact a company such as J&M Diamond Tool. Inc. in E. Providence, RI. Their style A & D bits are similar to the two no-name bits that work on my Cobra lathe.

- James Wendel likes this

I intend to live forever! So far, so good.

#9

Posted 16 December 2021 - 12:42 PM

Jay is correct:

One of the most important things is to have the tip of the cutting tool (hopefully it has a diamond insert) set in the correct position, which is just barely below the horizontal center with the comm turning into the top cutting edge of the tool.

And one other thing I've always been told: the cutting tool should be angled slightly back so it does not "catch" and be pulled into the comm.

Don

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#10

Posted 16 December 2021 - 01:28 PM

Don:

Thanks for the back-up on how to set up the cutting tool. Setting it up this way has always given me a perfect mirror finish so even though I'm not a machinist I figured I was doing it correctly. Maybe an experienced machinist like Dave Crevie or Rick Thigpen can chime in here.

Maybe Dave P. thought the comm was turning upward toward the tool as some comm lathes do, but one way or the other Dave P. always "corrects" me pretty much no matter what I say. ![]()

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#11

Posted 16 December 2021 - 01:35 PM

It wasn't my job description at Koford, but when I wasn't "general managing",cutting comms was one of the prodction tasks I would do.

I remember when getting a fresh diamond bit in, fine tuning the cut, adjusting the installation with .005" pcs. of air dam material.

IIRC, I could cut 48 raw comms in 45 minutes to an hour, with a fair amount of that time, cleaning out the comm slots.

I just asked Stu about adjustment.

His answer;

Hi Mike,

Usually you would want to set it as close as possible to the centerline.

If it is above it would tend to not cut easily and smear. If it is below it will cut easily but the chance of breaking would be higher especially if the comm truer uses V blocks.

- SpeedyNH likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#12

Posted 16 December 2021 - 02:09 PM

#13

Posted 16 December 2021 - 02:16 PM

…

Maybe Dave P. thought the comm was turning upward toward the tool as some comm lathes do, but one way or the other Dave P. always "corrects" me pretty much no matter what I say.

Jay,

The term “above “ when used by a machinist has nothing to do with gravity.

The cutter has to be above centerline, never below.

If I’ve corrected you in the past It’s because you’ve made a incorrect statement, nothing personal.

Dave

#14

Posted 16 December 2021 - 02:40 PM

However, I will try to place mine as close to center as that is both the normal lathe process and what two slot racing experts have said.

#15

Posted 16 December 2021 - 03:03 PM

On machinist's lathes you set the cutting tip at 0 degrees.

- SpeedyNH likes this

???-2/31/23

Requiescat in Pace

#16

Posted 16 December 2021 - 03:04 PM

Google it and you'll get every suggestion on tip placement.

Above, below, and dead on.

Most of those aren't for someone cutting a slot car comm.

I'm sure you have plenty of disposable arms you can experiment on., to see what works best for you.

If you are using a cutting bit with a diamond tip, most important for someone not doing production work, is to not "hot rod" the lathe.

Take your time.

Not sure if it was mentioned, but also most important with a diamond tipped bit, is to never stop or start the lathe motor, with the tip touching the copper.

Putting a few thin spacers on the comm side will facilitate running the bit off the end of the comm, to stop, to inspect it.

With the 10,000(?) + comms I must of cut at Koford, I always had a foot pedal, which made life much easier.

- SpeedyNH and Isaac S. like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#17

Posted 16 December 2021 - 03:19 PM

I use to be obsessed with lathes and mills. I've watched 10,000 youtube videos and read tons on it as well. Practical Machinist forum is really good. I'm sure there's exceptions, but I can't recall anyone suggesting anything other than 0 degrees. Setting up your tool height is one of the basics of lathe work. I usually face the end off of some round bar stock to set mine. Too high or too low and it will leave a "tit" in the middle. Adjust until the tit disappears and your tool height is set at 0 degrees.

- SpeedyNH likes this

???-2/31/23

Requiescat in Pace

#18

Posted 16 December 2021 - 03:27 PM

#19

Posted 16 December 2021 - 03:34 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#20

Posted 16 December 2021 - 04:21 PM

Regarding setting the tool....

I've never used a commutator lathe, but I spent 20 years as a Tool & Diemaker before I got into another line of work. . My vocational high school shop teacher went over this literally on day one when we were taught how to use a lathe.

You always set the tip of your cutting tool to the center. Below center and the piece will try to grab and walk over the top. Above center and the cutting edge isn't doing its job. Instead the tool is pushing against the piece being turned.

Hopefully, that makes sense... If we were sitting around somewhere, I'd get out some paper and pencil and draw it so it's more understandable.

- Phil Smith, Rob Voska and Guillermo Suar like this

#21

Posted 16 December 2021 - 04:36 PM

I addition to being different colors, the diamond tip has more shine from being ground than does a bit's steel. If a bit was solid carbide, it should be market so as not to confuse it with HSS. Those two materials may have slight color differences, but mine are packed away at the moment.

I don't recall where it came from, but I cut comms below center by turning the diamond bit upside down & using the proper rotation direction. This may have come from Monty Ohren, but I'm not certain of that.

I intend to live forever! So far, so good.

#22

Posted 16 December 2021 - 05:58 PM

Thanks guys, all helpful comments.