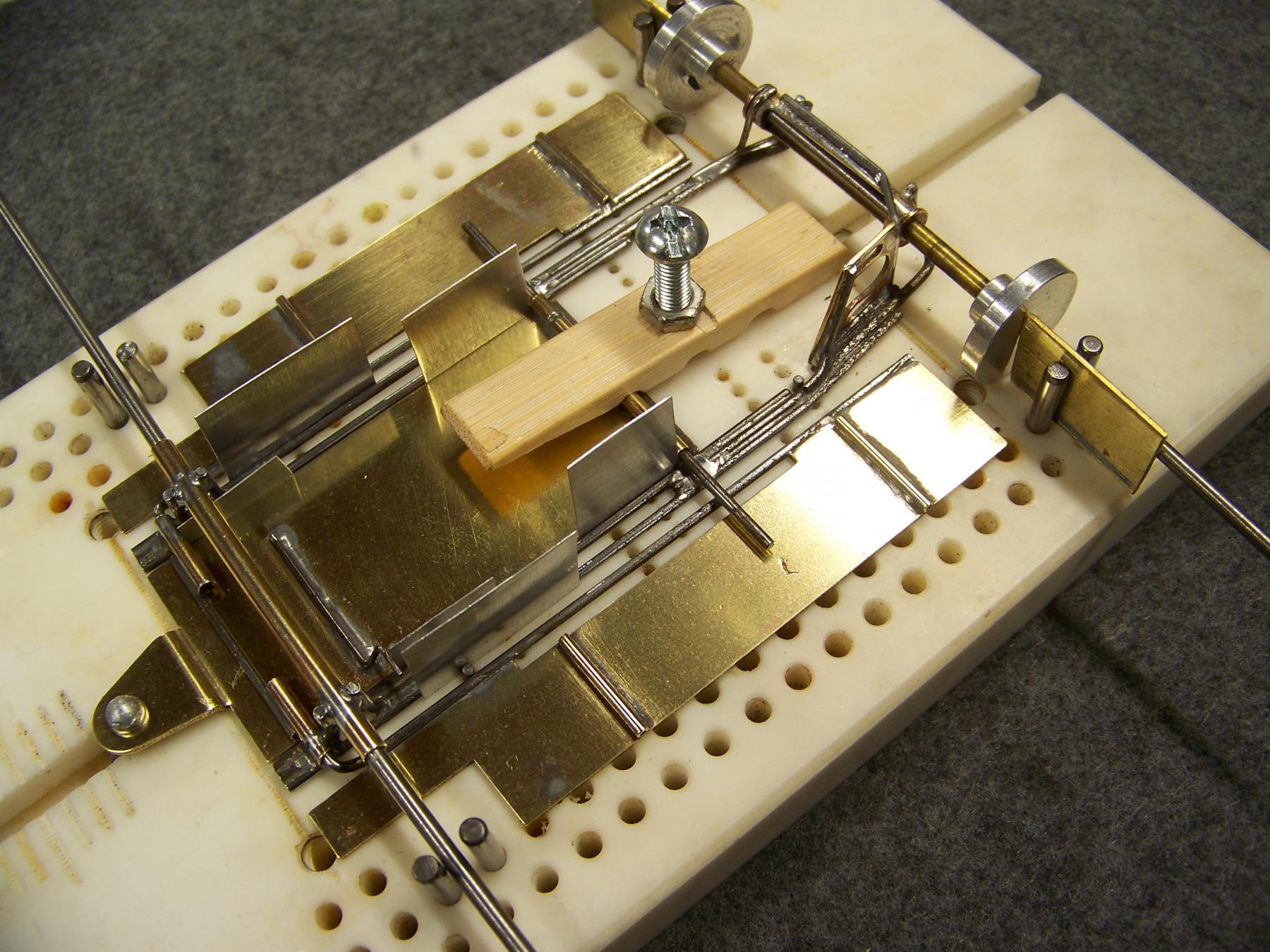

Ive built several chassis out of brass tubing many moons ago, but nothing really fancy using panio wire and flat brass sheet.

Ive sourced some 1.5mm brass sheet along with that nikel plated panio wire to make soldering easier and got a piece of stone benchtop with a slit cut down the middle to use as a jig.

Are there any good design guides out there? ive been studying many photos to get some ideas, but its hard to sometimes see how its designed to work without examining one in my hands.

I kinda like the whole torsion bar idea and the tuning fork designs ive seen. Will probably be building some angle winders.

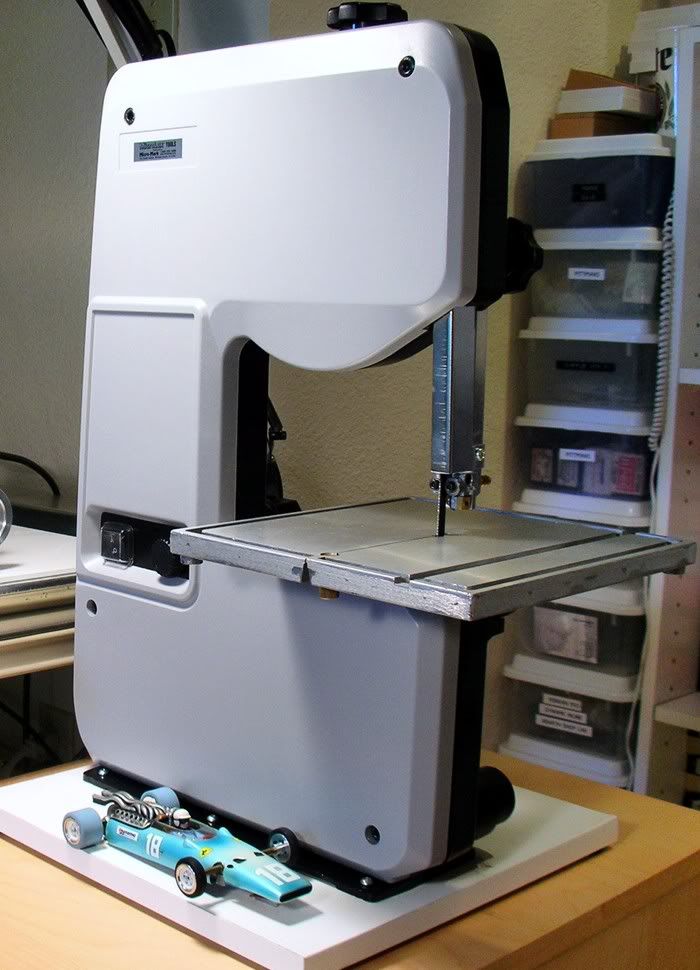

One challenge is cutting the brass, its hard with a hacksaw and the blade wanders requiring you to cut larger then file to shape. Quite a bit of work.

Is there any type of saw that works better? Im also looking at CNC/laser cutting the stuff potentially. I could draw up the whole protoype and even 3D print it to see how it all fits and make adjustments before making the final part.