Larry, not to steal Rick's thunder, but from a historical perspective, most slot cars from '65 were not being built using brass rod.

Scratchbuilt Cheetah

#26

Posted 02 May 2023 - 03:04 PM

I intend to live forever! So far, so good.

#27

Posted 02 May 2023 - 03:43 PM

True, but I didn't realize that Russkit's Scratchbuilder's instructions already recommended brass rod for the bottom rails! Thanks for pointing that out Rick.

Don

#28

Posted 02 May 2023 - 03:57 PM

Even in the early 1966 Rod & Custom series the fastest qualifier in the first race used a "non-jail door" pin tube chassis. We need to remember that the vintage road race chassis did not begin with a heavy brass rod jail door design. Those evolved as motors got faster and tires with more traction were developed:

- Tex likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#29

Posted 02 May 2023 - 04:05 PM

True, but I didn't realize that Russkit's Scratchbuilder's instructions already recommended brass rod for the bottom rails! Thanks for pointing that out Rick.

Don

That surprised me too Don, especially since my kit came with all pin tubes and no rods. ![]()

![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#30

Posted 02 May 2023 - 07:50 PM

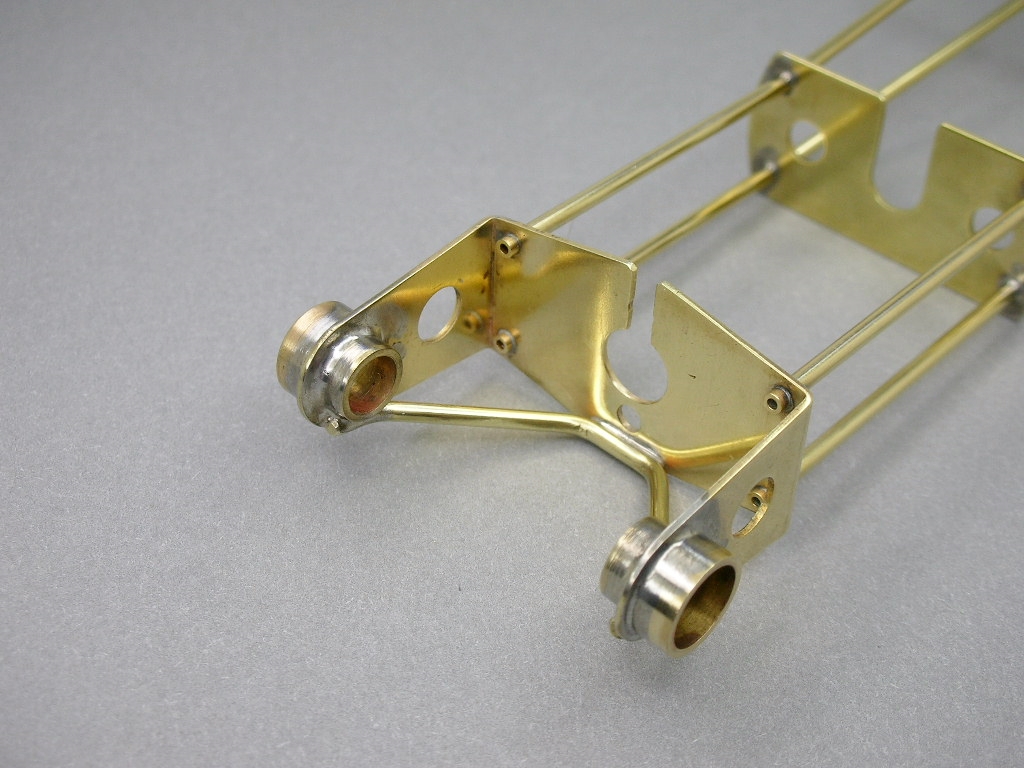

An "olden time" rear axle brace.

A simple U-shape brace is much stronger, is easier to make and will become almost universally used.

- Pablo, NY Nick, Alchemist and 2 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#31

Posted 02 May 2023 - 09:59 PM

Sweet birdcage

- Alchemist likes this

Paul Wolcott

#32

Posted 04 May 2023 - 03:46 PM

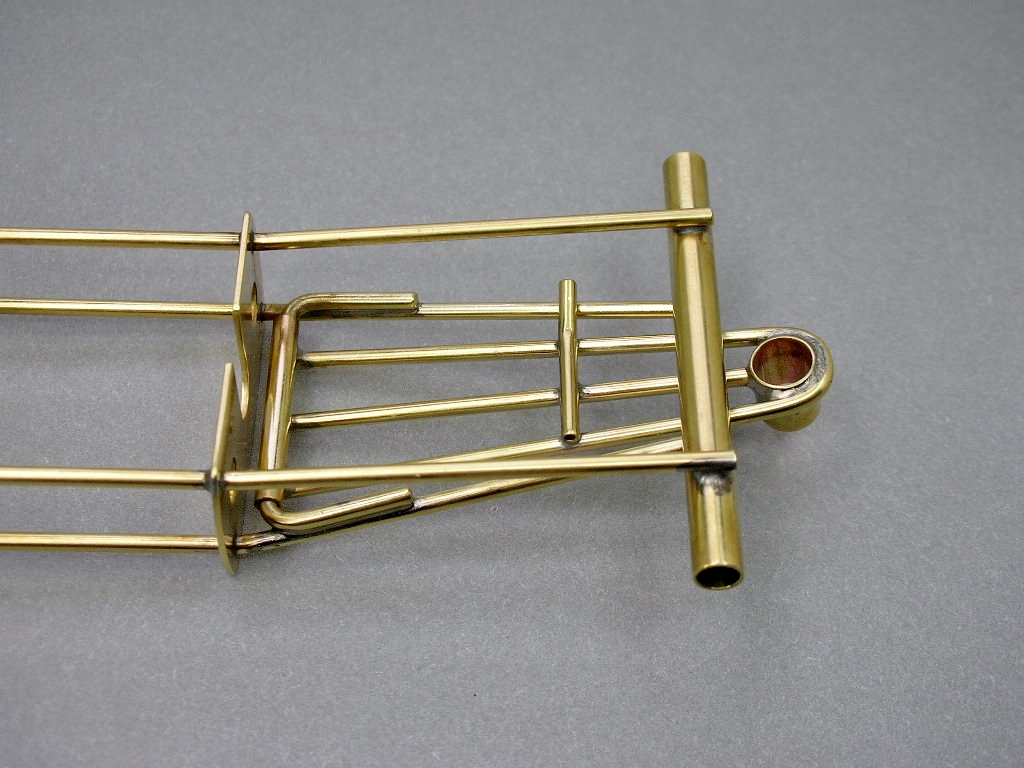

Thanks Pablo. Here's the drop arm hinge:

2 L-shaped rods and a hinge tube:

More brass tubes for the drop arm:

I added a down stop with very limited travel. It might be beneficial to have as much of the cars weight on the guide as possible.

- Pablo, NY Nick, Alchemist and 1 other like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#33

Posted 05 May 2023 - 11:01 AM

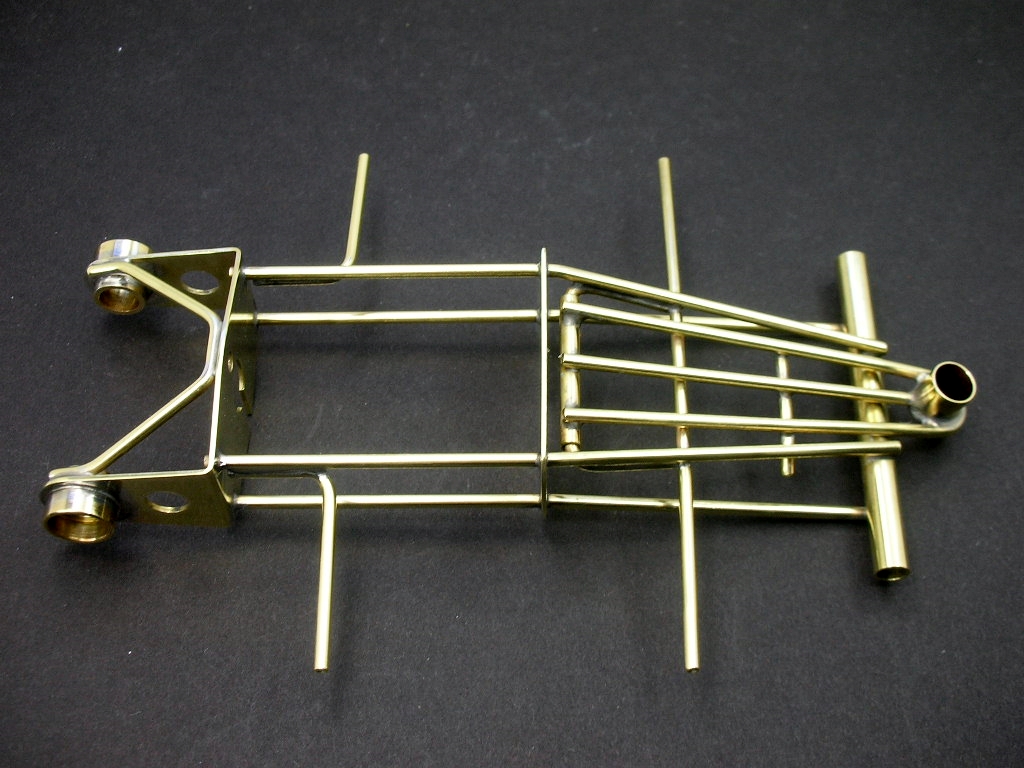

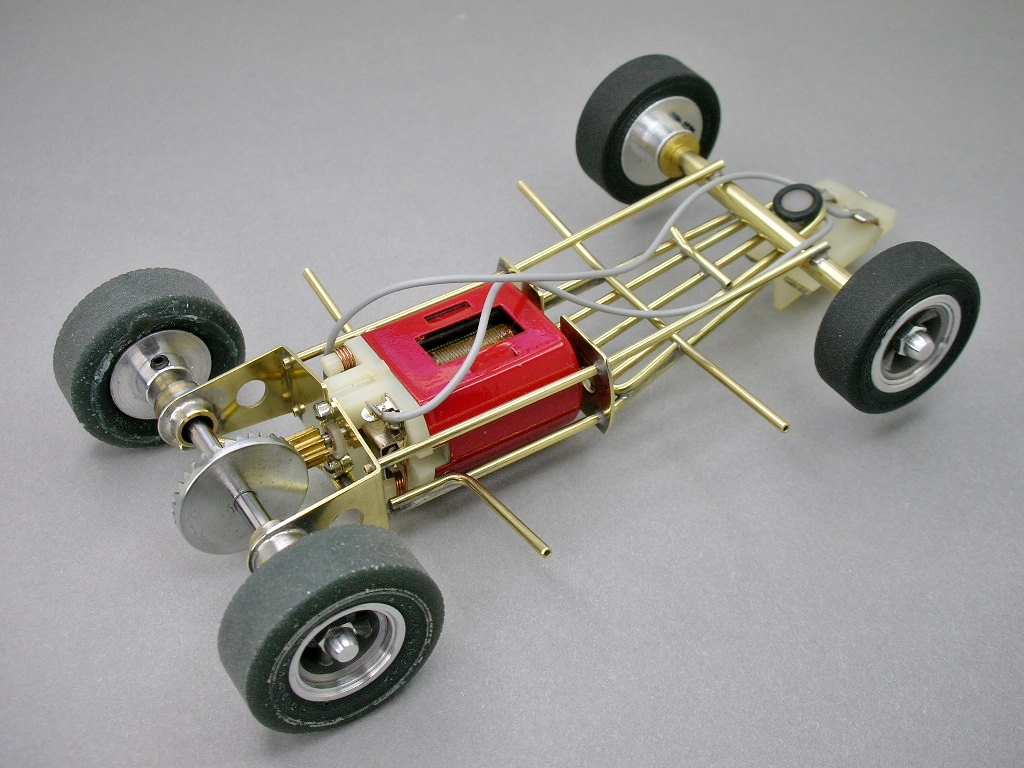

The chassis is finished:

I tried to keep my 20/20 hindsight in check and not add any "upgrades":

I couldn't resist getting the body mounted even before I assembled the finished roller:

The stance has a slight "California rake".......I'm liking it so far.

- Jairus, slotbaker, Tex and 9 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#34

Posted 05 May 2023 - 11:20 AM

I'm liking it, too.

- Geary Carrier likes this

#35

Posted 05 May 2023 - 11:40 AM

The "stance" is perfect Rick!

Thanks for sharing.

Ernie

#36

Posted 05 May 2023 - 01:39 PM

Much awesomeness ... I especially love the drop arm. Rick, was this body pre-trimmed or did you do that. If it was you, great job!

#37

Posted 05 May 2023 - 01:45 PM

Love the chassis build with the motor angle.

Beautiful work.

#38

Posted 05 May 2023 - 03:07 PM

#39

Posted 05 May 2023 - 04:27 PM

Thanks to everyone for your encouragement. I appreciate it.

Here's a before picture of the disassembled motor:

The motor ready to go back together with new old stock parts:

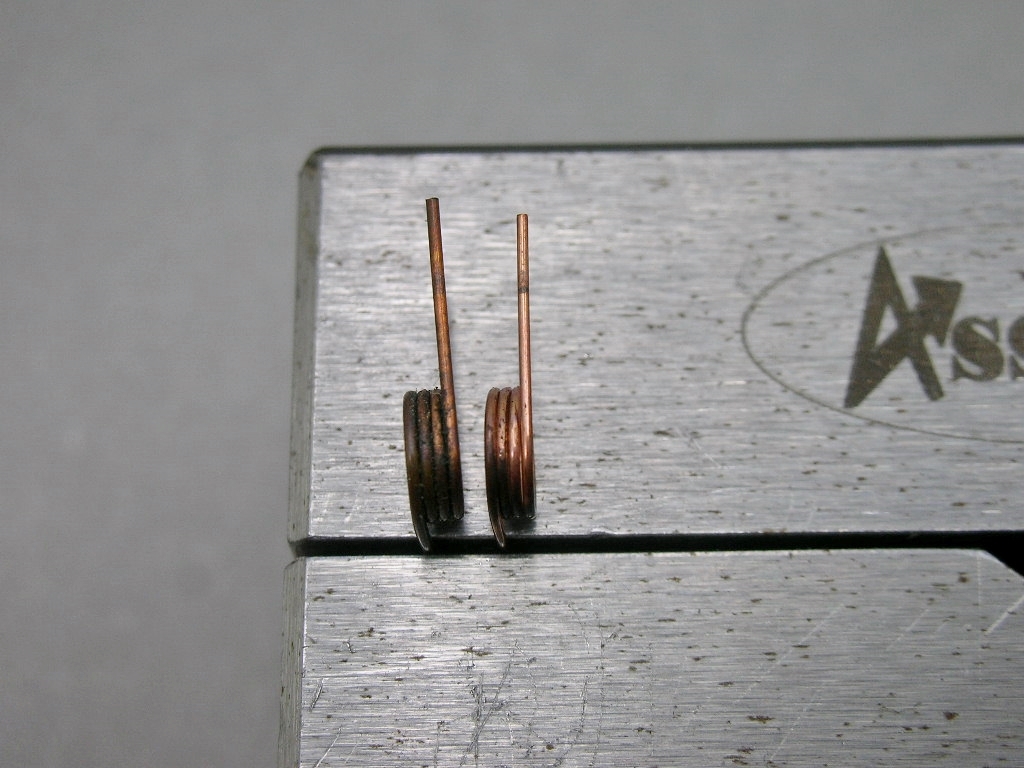

The motor has heavier brush springs. The same number of coils but the wire is heavier. Heavy spring on the left compared to a Russkit 23 spring on the right:

- Tex, Peter Horvath and Geary Carrier like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#40

Posted 05 May 2023 - 06:05 PM

Cheetahs always win. I may have one of those decals, if I find it do you want one, Rick?

Paul Wolcott

#41

Posted 05 May 2023 - 07:29 PM

Rick, do you have a Fiddlestick to compare the tension of your big springs to that of the Russkit 23 springs? Any spring can be rebent to either increase or decrease its tension.

I intend to live forever! So far, so good.

#42

Posted 06 May 2023 - 08:04 PM

Sorry I didn't answer you sooner Larry. The Lancer body was factory trimmed but I refined it especially the wheel openings. I use a mandrel like a plastic tire tube wrapped with 320 grit sandpaper. Often the wheelbase and wheel openings are not the same from one side of the body to the other. My personal experience with Dynamic bodies has been especially bad in this area. ![]()

I don't have a Fiddlestick Bill so I can't compare the stock vs aftermarket brush spring tension. I have swapped out springs and adjusted brush spring tension based on the amp draw on the analyzer.

- Larry Horner likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#43

Posted 08 May 2023 - 11:01 AM

Fabulous Rick - I'd almost be tempted to leave it like that!

Don

#44

Posted 08 May 2023 - 11:21 AM

I'm adding all the goodies to make the roller right now Don. I'm interested to see if I can balance this lightweight, short wheelbase, short guide lead and rather tall cars power and traction. I hope it will not necessarily be the fastest car around the track but fun to drive. We'll see.

But first here are a couple of much maligned parts for the project car.

The Russkit Small Slant guide:

And the MDC pot metal gear, deburred and polished:

- Pablo and Peter Horvath like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#45

Posted 08 May 2023 - 11:33 AM

The more I look at that body stance, the more I like it. I think it is probably as close to the real car as I have seen. The nice thing about the Cheetah is that it doesn't have the pronounced fender flares of some cars. That makes it easier to match the wheel openings side-to-side.

I hate to allow myself to secumb to temptation to build another Cheetah, but I bet I will after seeing this thread. Might go sidewinder this time.

#46

Posted 08 May 2023 - 12:11 PM

Dave, Dom's Raceway in NJ pulls clear Cheetah bodies, unless you want to use a hard body. The Alan Green Cheetah is very popular to use in photographic & other articles. You're apt to see it most anywhere.

I intend to live forever! So far, so good.

#47

Posted 22 May 2023 - 05:11 PM

I've finally got all the pieces in one lump:

I prefer to use a steel pinion with a pot metal crown gear. This motor has had the armature shaft cut short so I went with this long Cox brass pinion. I'll make sure not enter any 12 hour enduro races. ![]()

I've been struggling with how to attach the all important "honk'n side pipes" to the body. I made a little sheet styrene thingie to hold the side pipe and tried to attach it to the body.

It looked BAD.......as in NOT GOOD. Jairus could make it work and look great but I just don't have the modeling skills he makes look so easy.

Plan B for me is to attach the pipes to the chassis with metal fabrication and soldering. That's something I do know how to do and I'm fabricating the mounts now............

- slotbaker, Pablo, Jencar17 and 5 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#48

Posted 23 May 2023 - 08:38 AM

"Plan B for me is to attach the pipes to the chassis with metal fabrication and soldering. That's something I do know how to do and I'm fabricating the mounts now............"

I think that method is a good way to go. I chromed the brass with the chrome pen. Love those pens.

This is the only car I restored that has something similar. I think this is what you are thinking?

I look forward to seeing what you come up with.

- Peter Horvath and olescratch like this

#49

Posted 23 May 2023 - 08:38 AM

I really like what I see so far. I'd like to copy it with some minor changes. I have a couple more wide brackets that I believe are Unique, and would be a good starting point. Previously I used piano wire with this bracket. Want to do one in tubing like yours.

#50

Posted 23 May 2023 - 08:08 PM

Thanks Dave,

Brass pin tube chassis are part of slot car history and make a fun build. I hope you go for it! ![]()

Cool looking pipes Martin.......and very nice wheels too.

The first Cheetah's had long tube headers and you can see all 4 pipes entering the side pipe like this continuation version:

Most of the later race car versions have side pipes similar to this car that I'm modeling mine after. They are huge and stick out past the rear tires: ![]()

I'm using some 3/32" X 3/16" rectangular brass tube and big honk'n parts box plastic pipes:

An L-shaped 1/32" X 1/4" brass strip was soldered to both frame rails. They are about 1/8" above the track:

The rectangular tube was soldered to the strip:

Here everything is trimmed, cleaned up and the pipes installed:

- slotbaker, don.siegel, Pablo and 10 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...