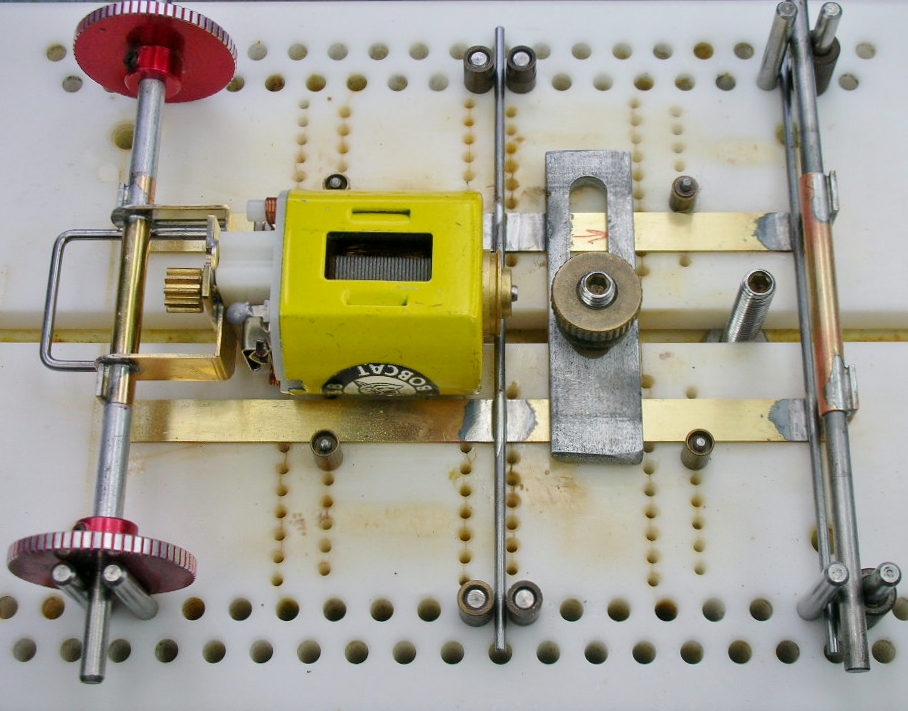

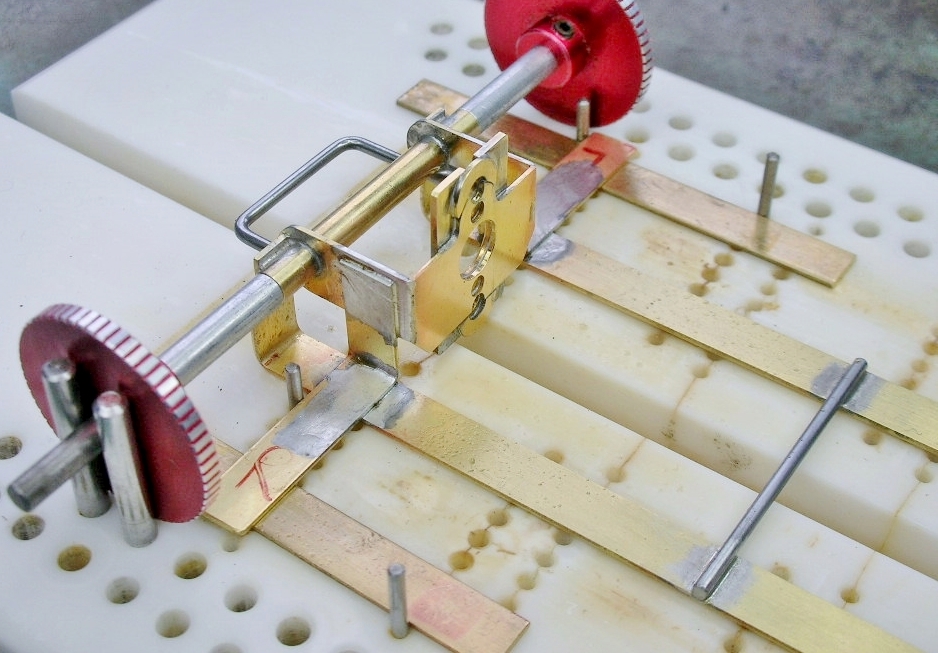

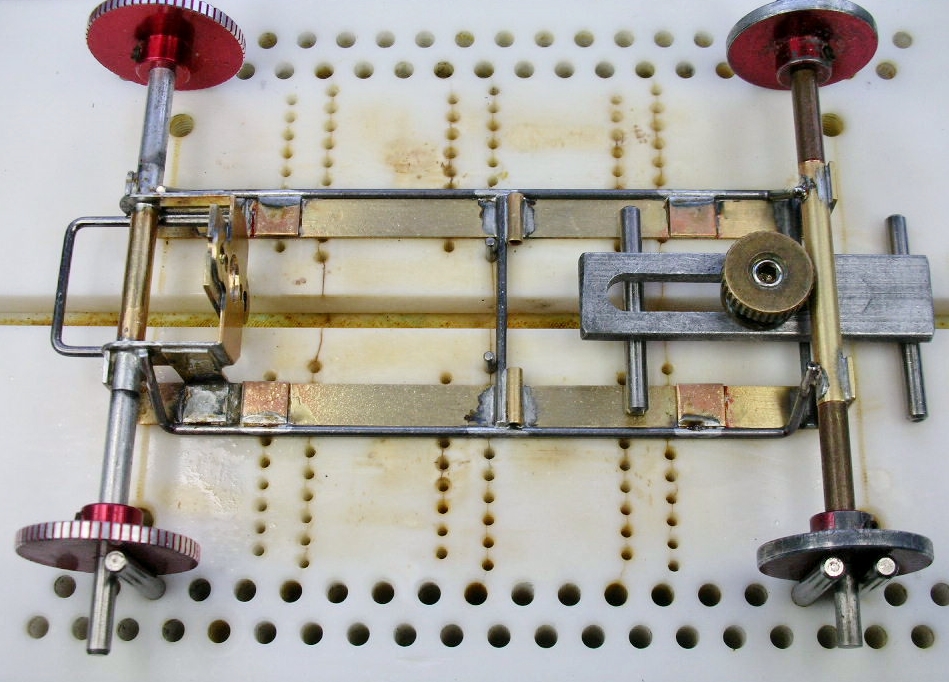

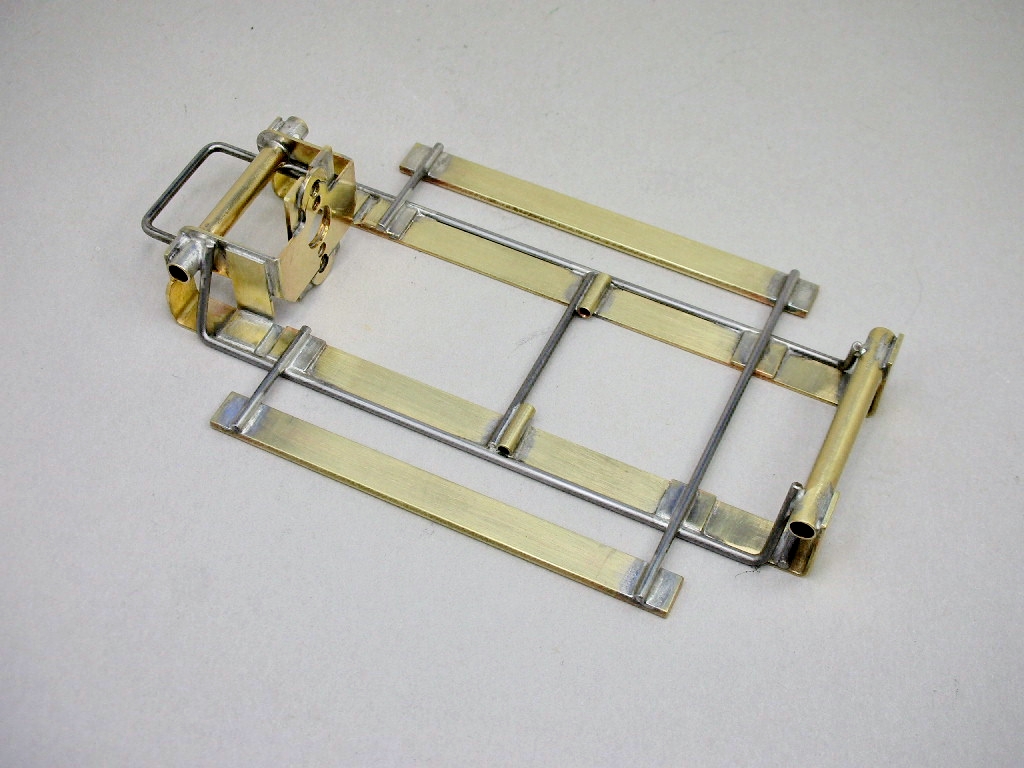

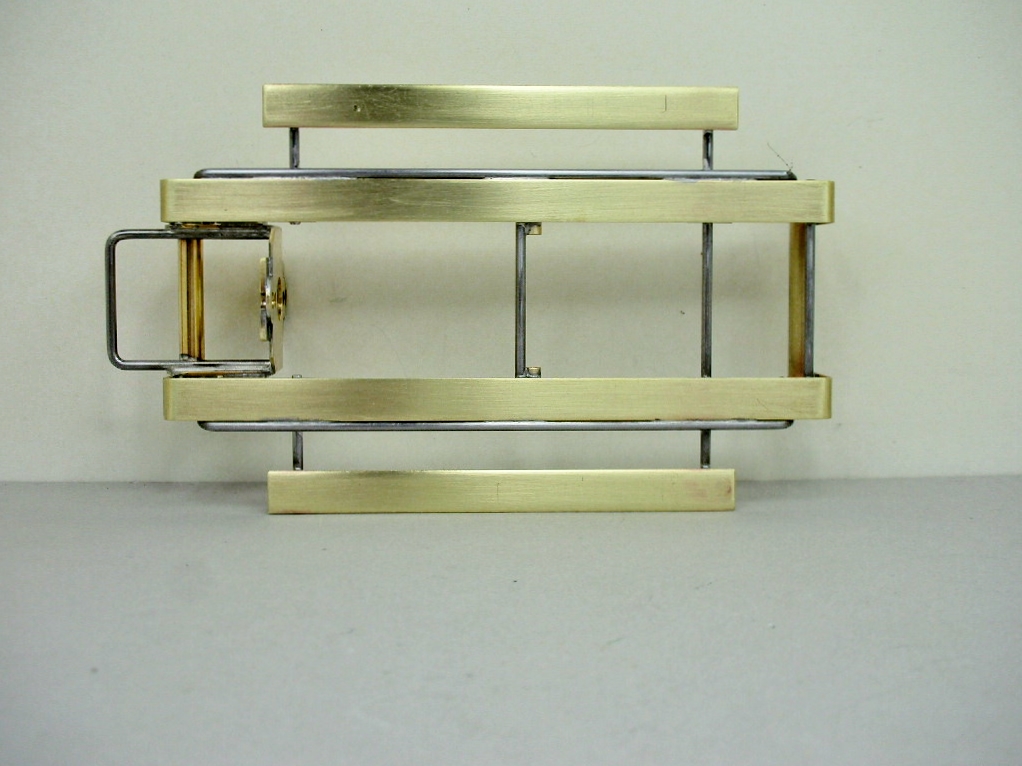

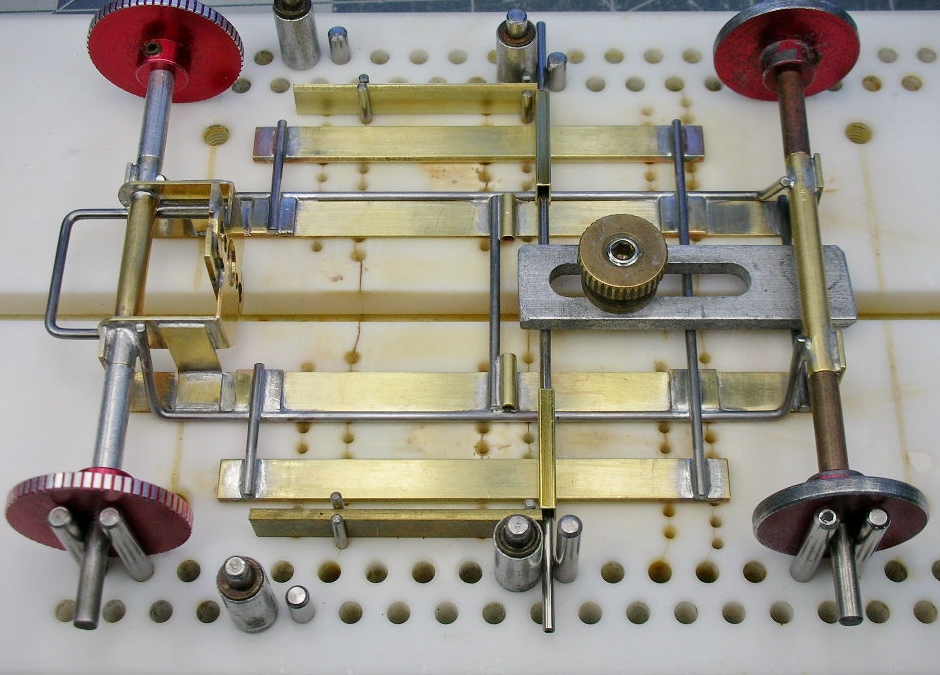

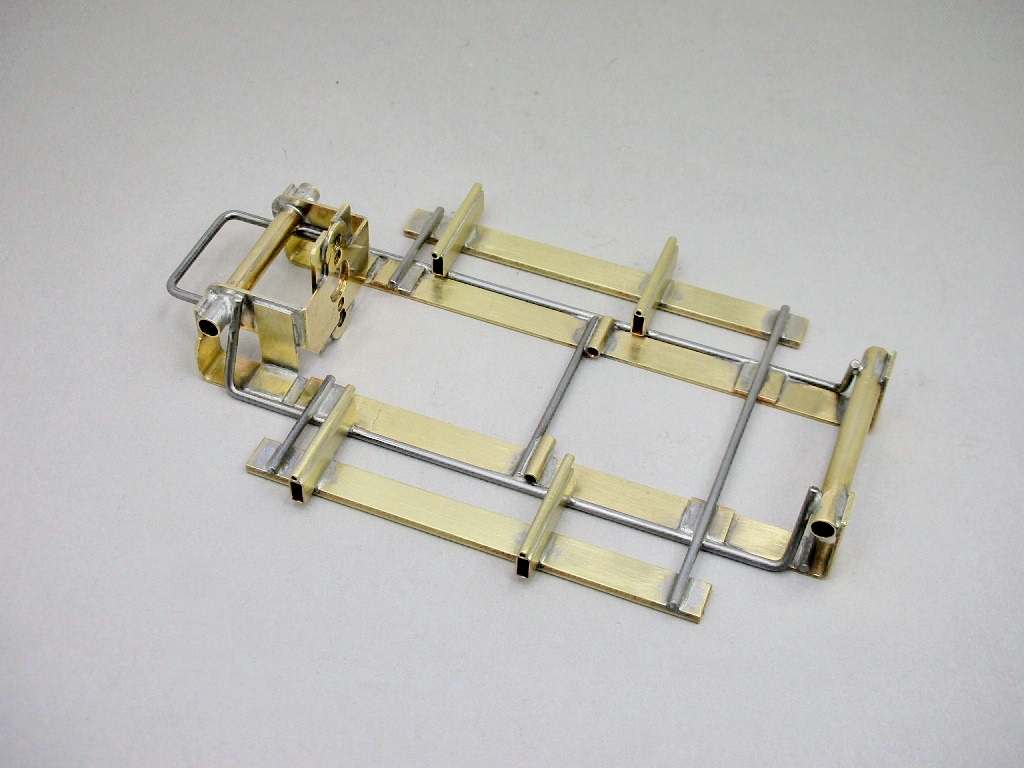

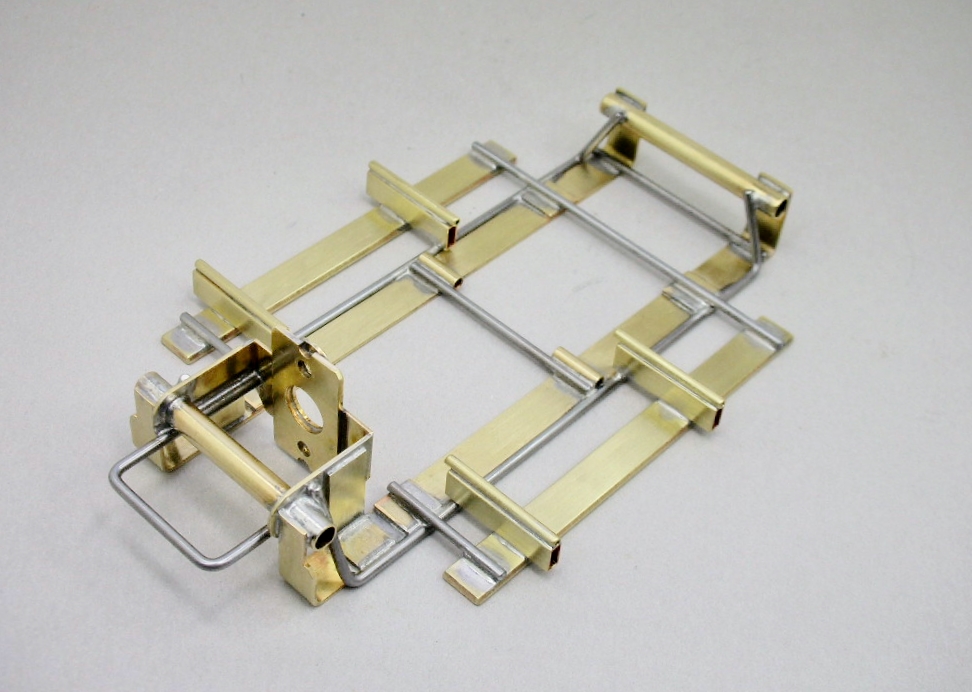

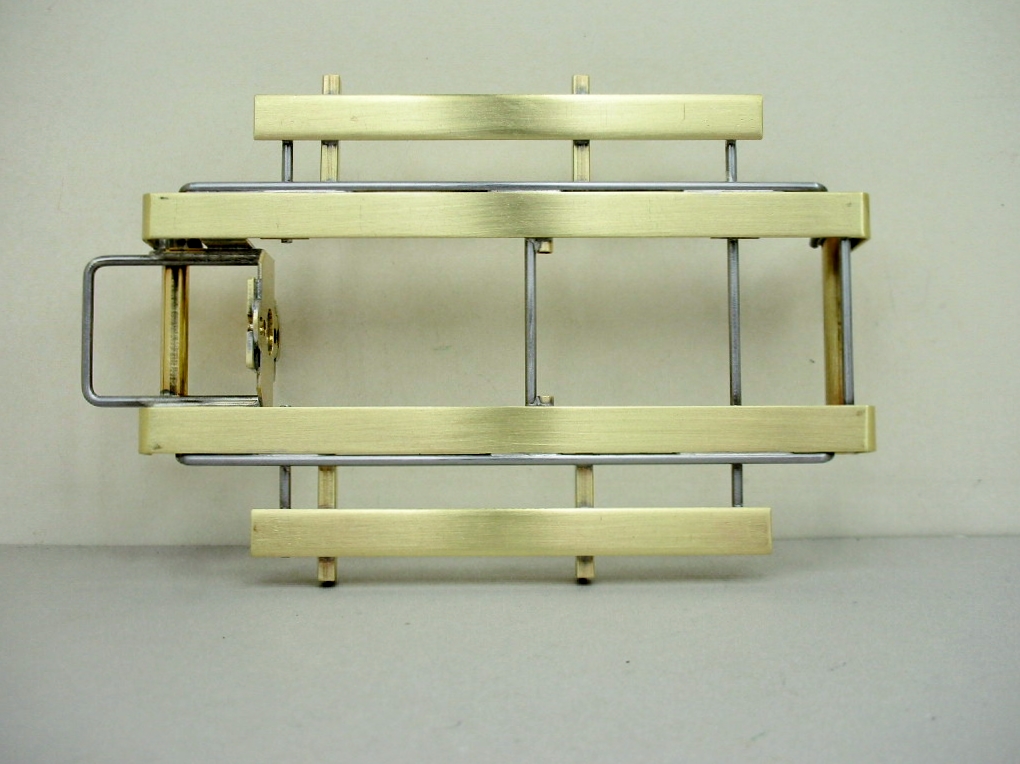

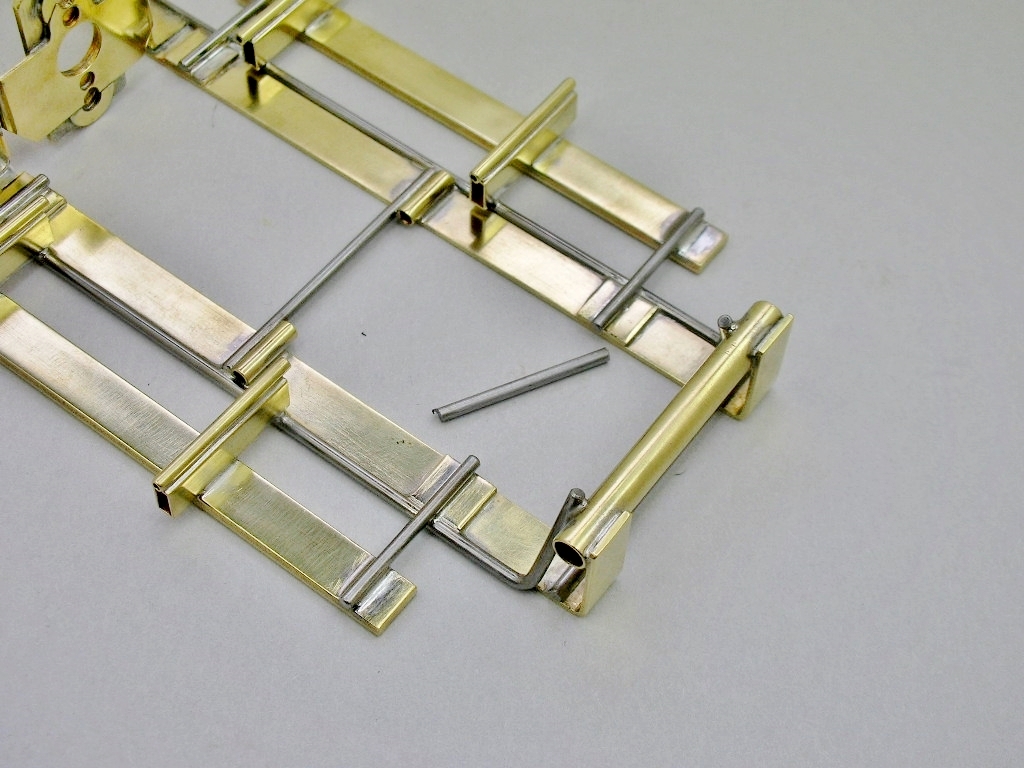

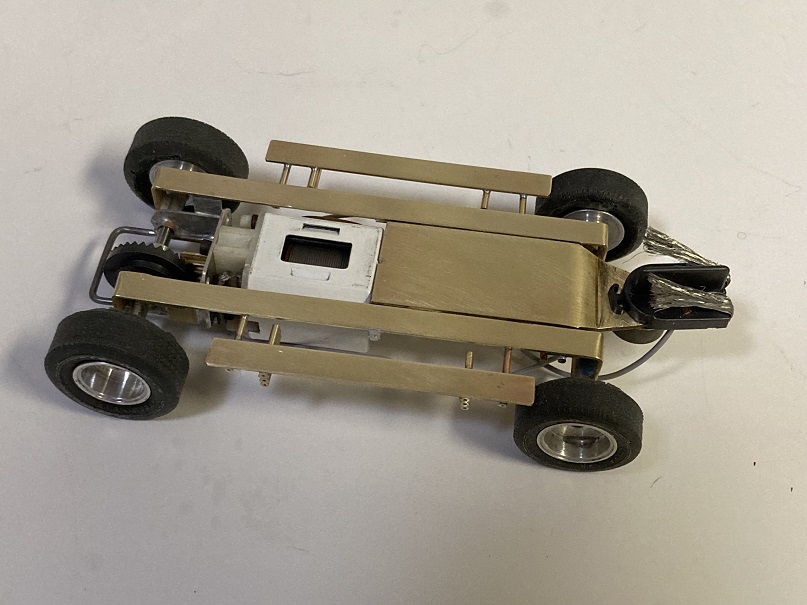

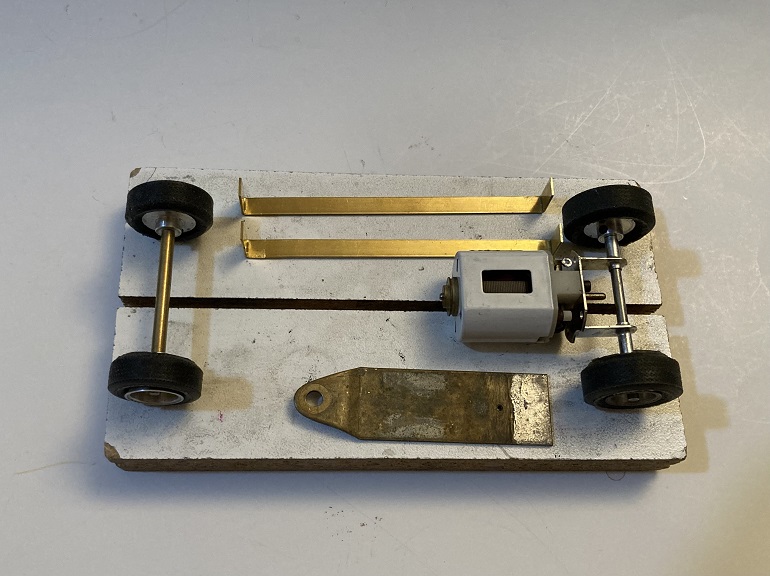

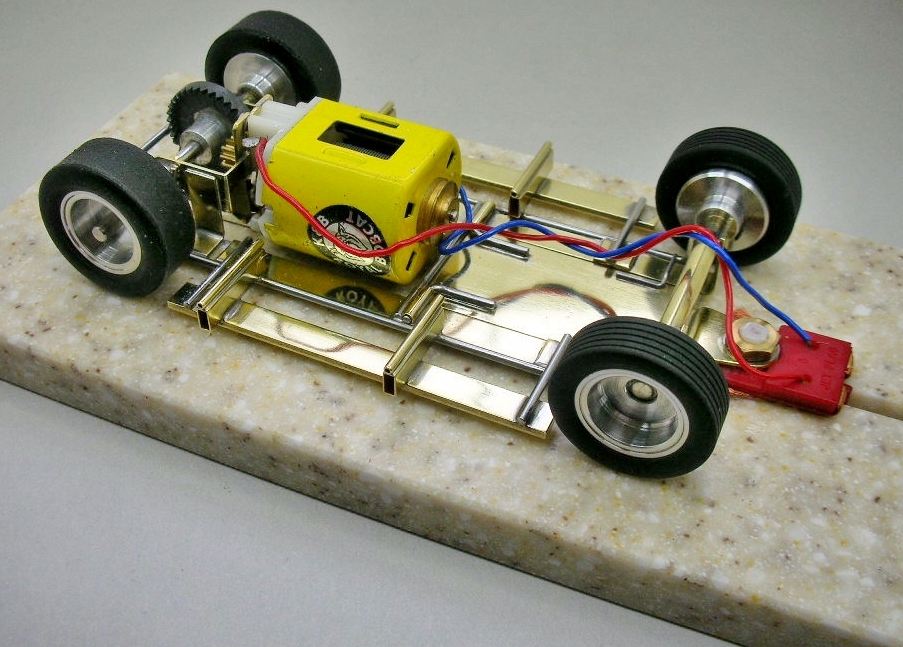

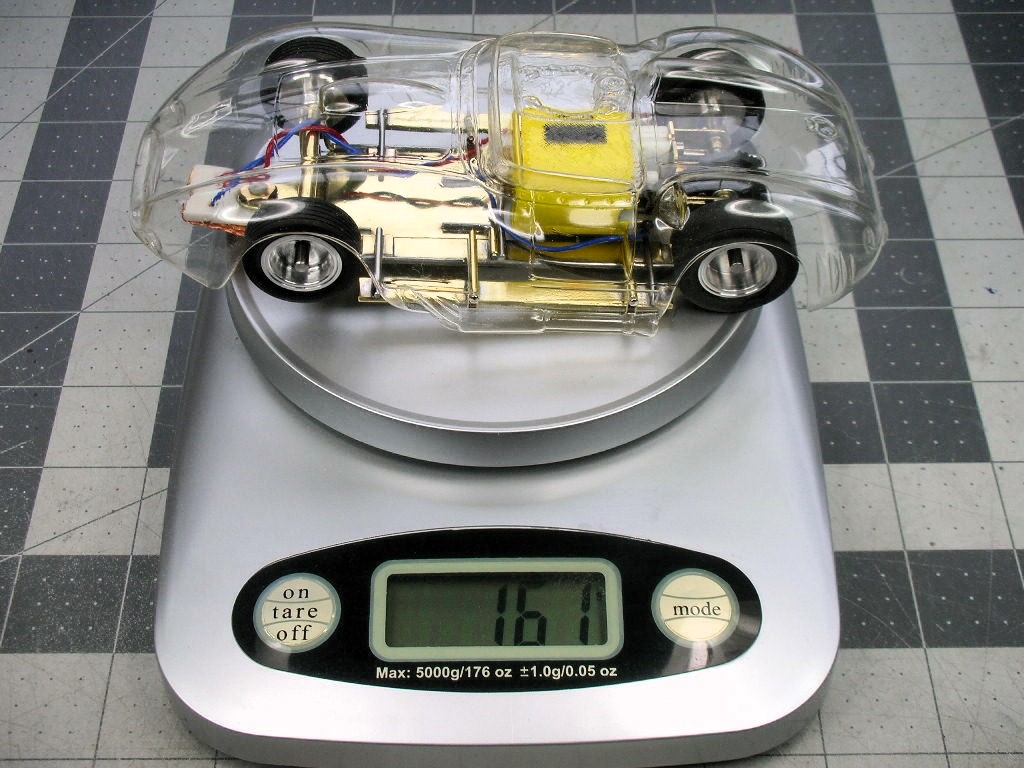

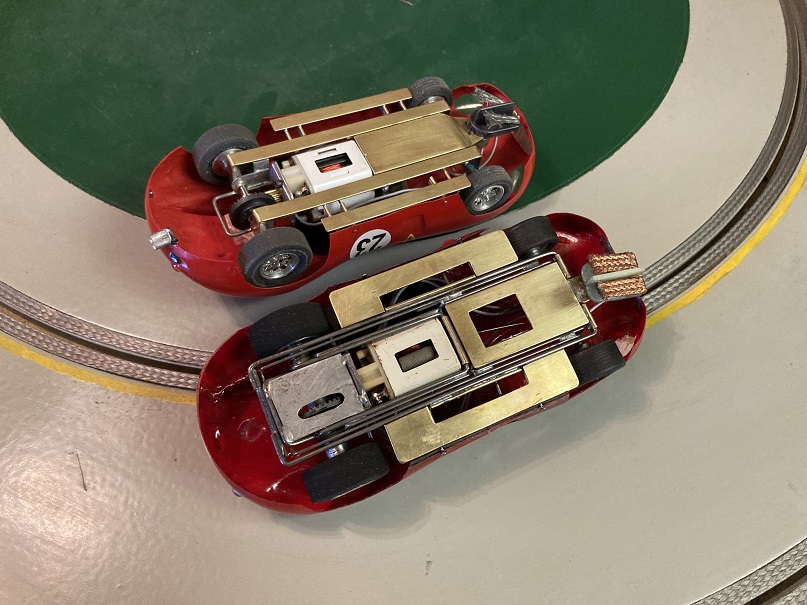

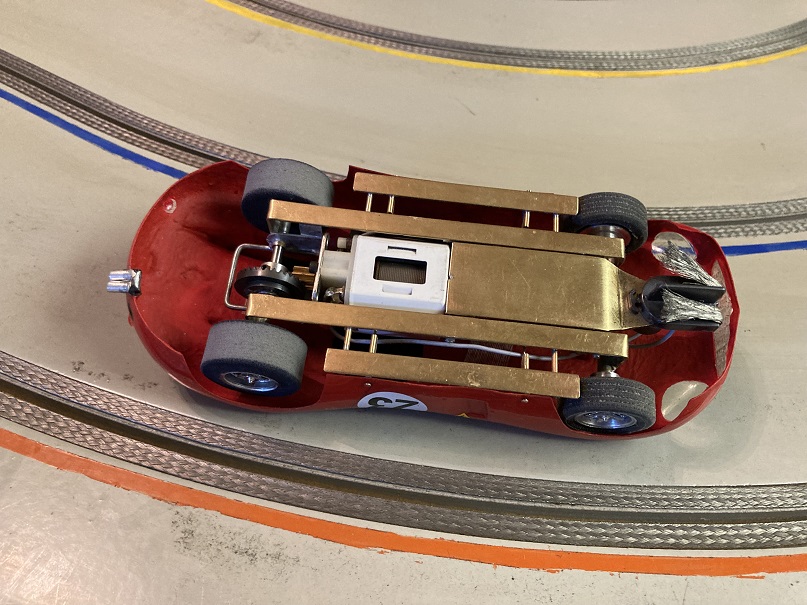

With the chassis finished, the wheels and tires all trued and ready to go I decided to just throw the thing together and get it on my track for a shake down. I'll shorten the long axles and clean things up later.

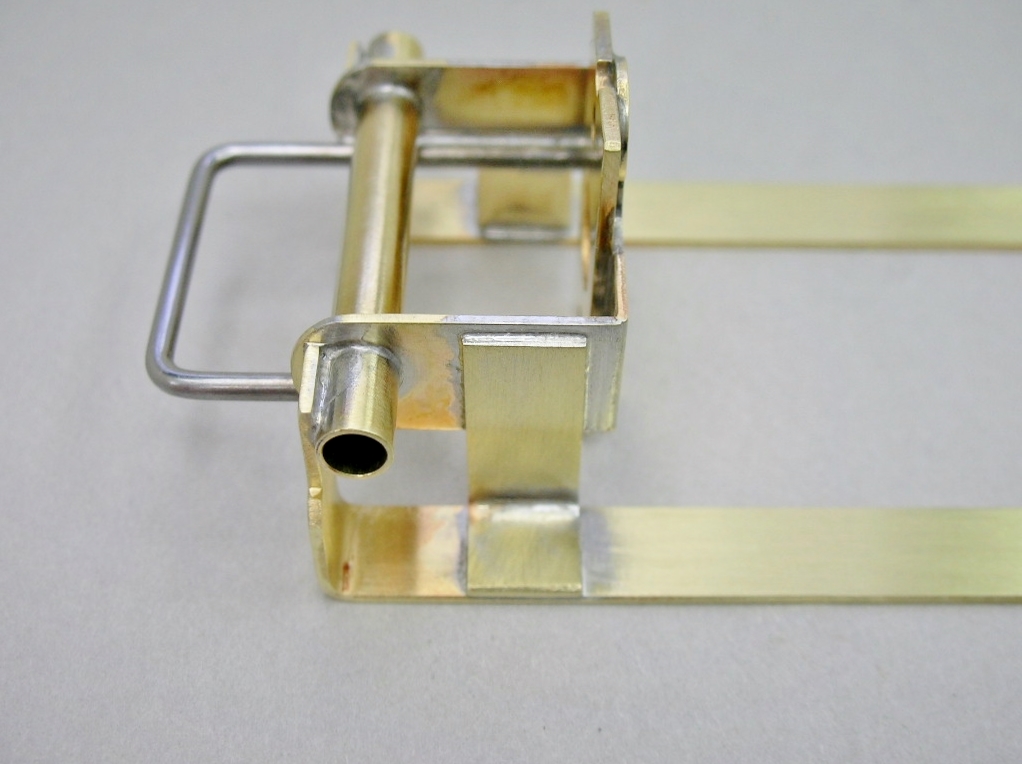

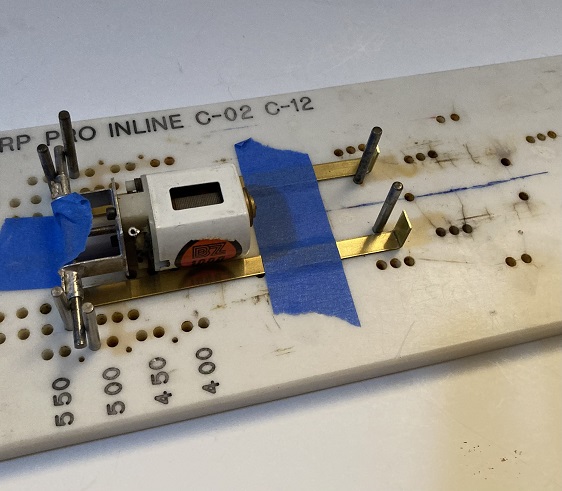

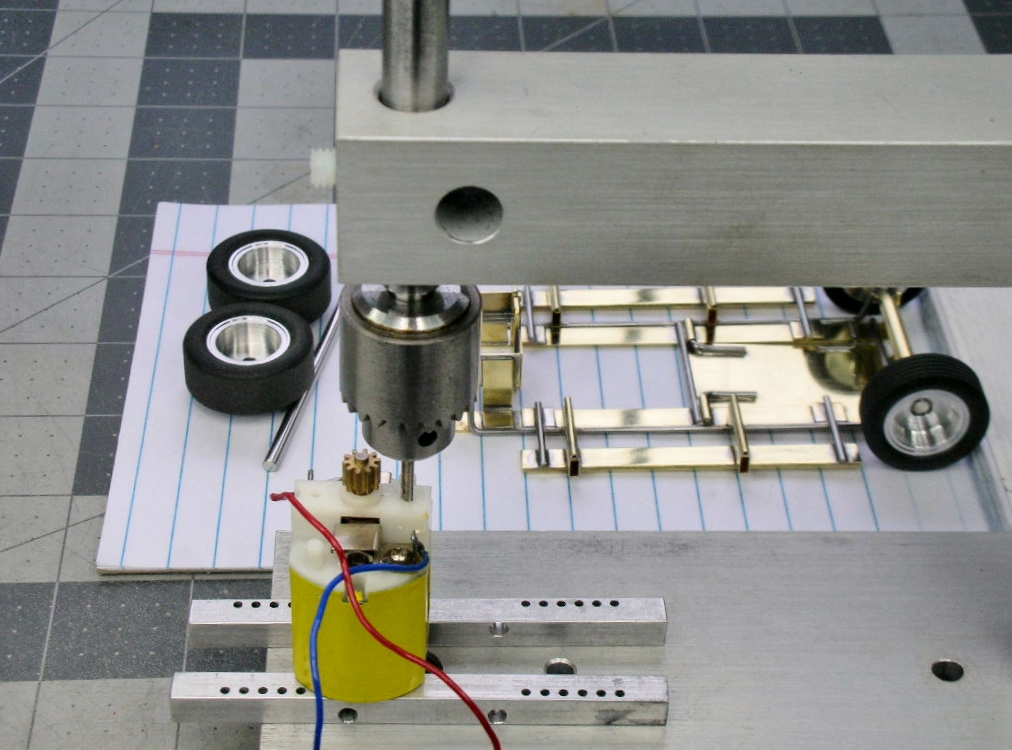

Since the endbell was already cracked at the bearing I decided to tap the mounting holes so nothing else cracked. With the brushes removed any plastic chips can be blown out of the motor:

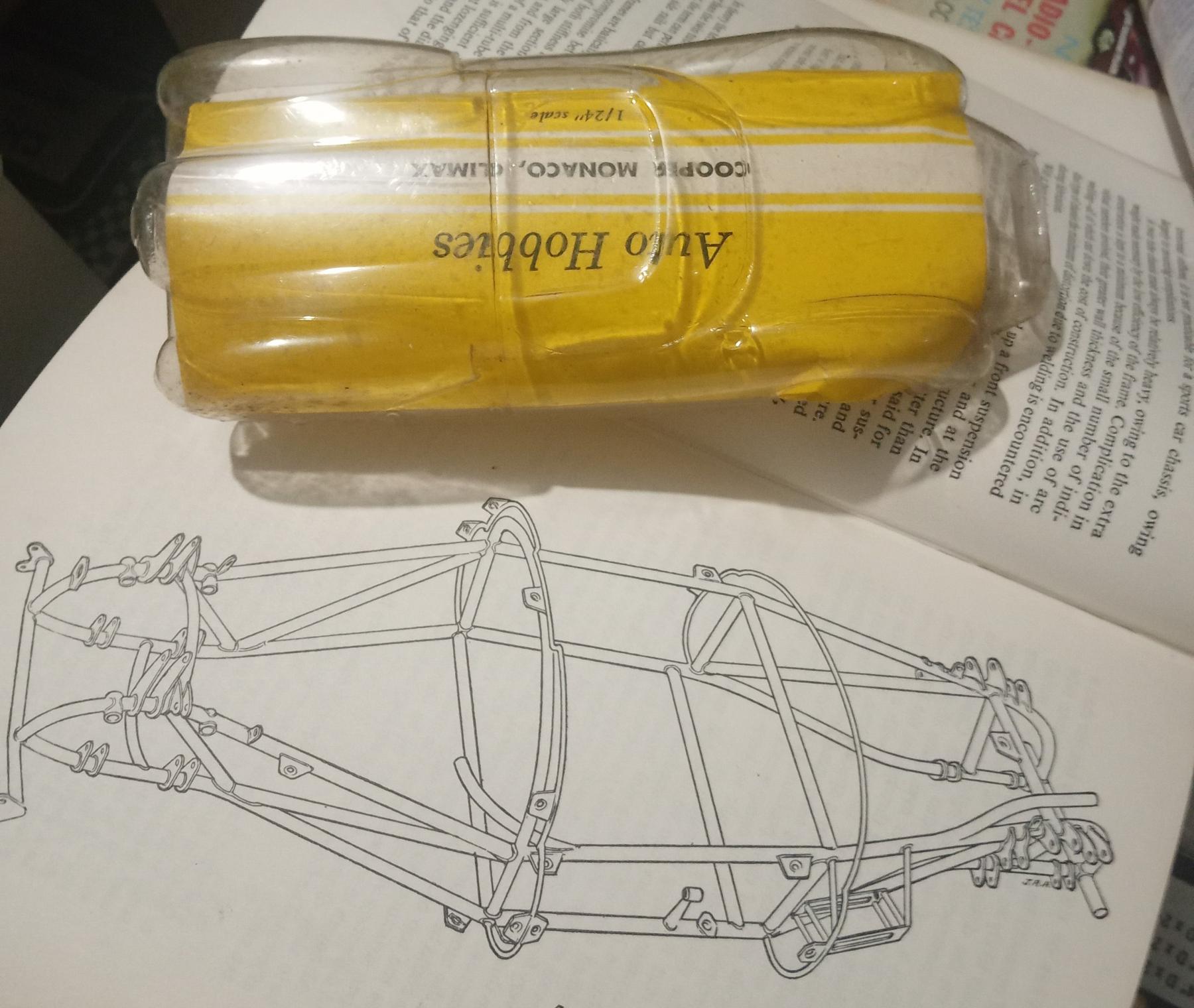

Since this is a 1971 build I used a JET flag and attached it with a nut:

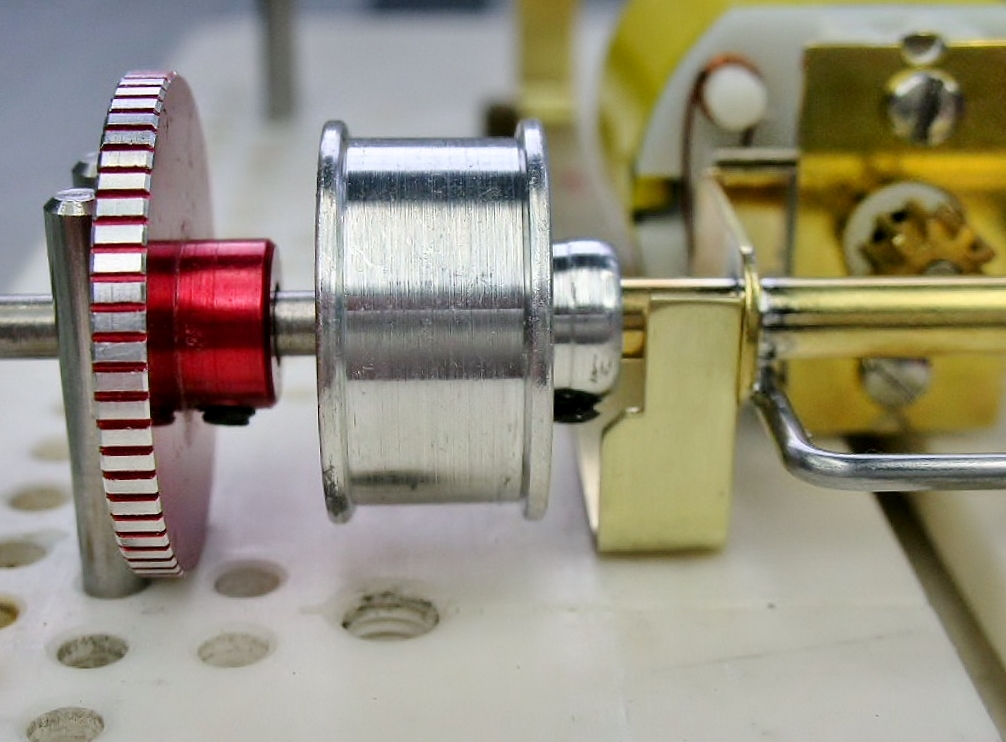

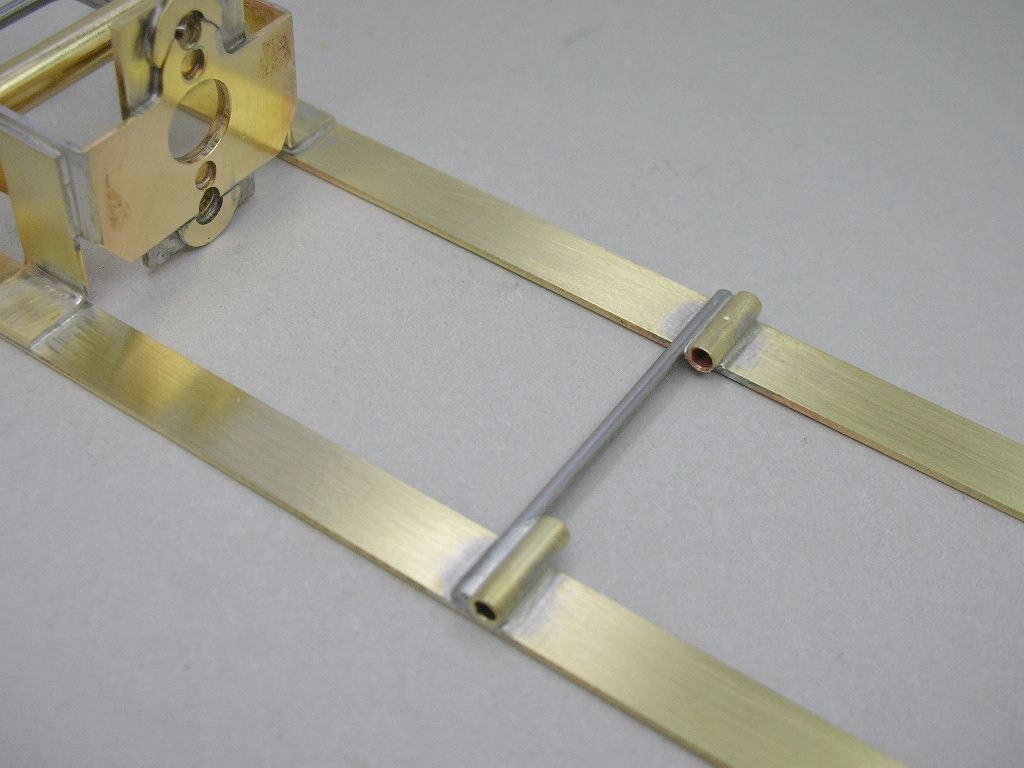

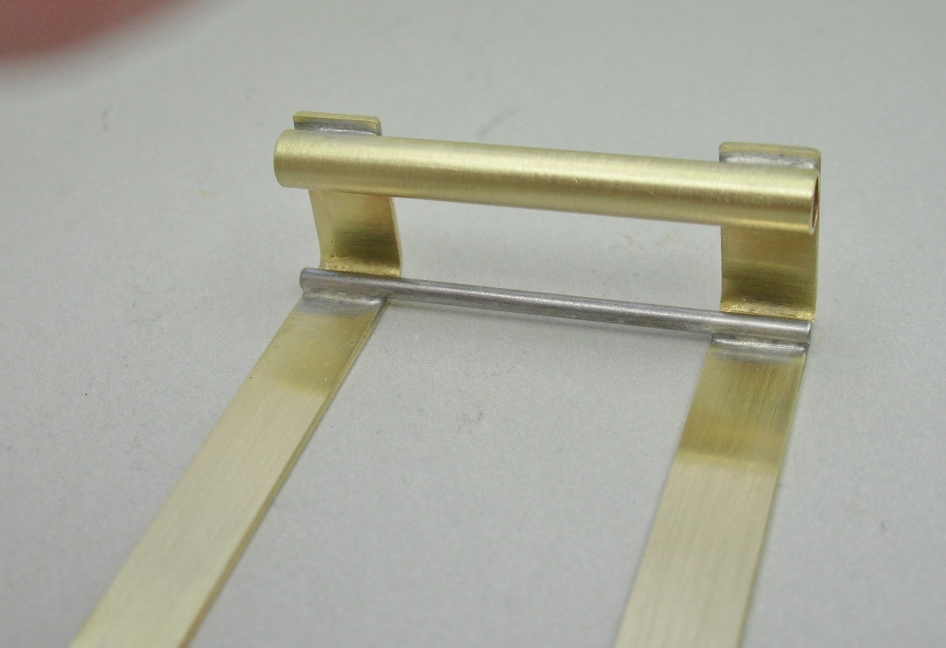

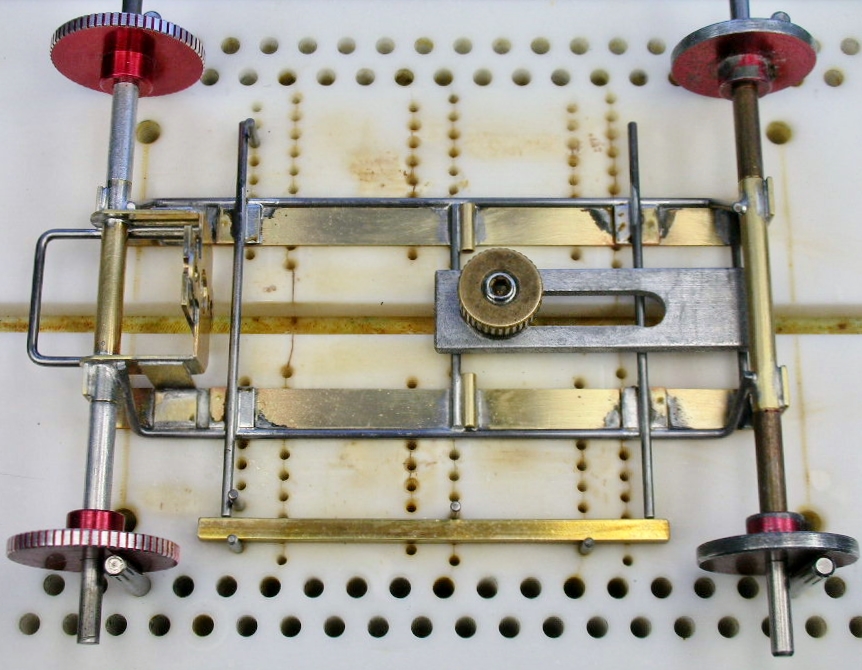

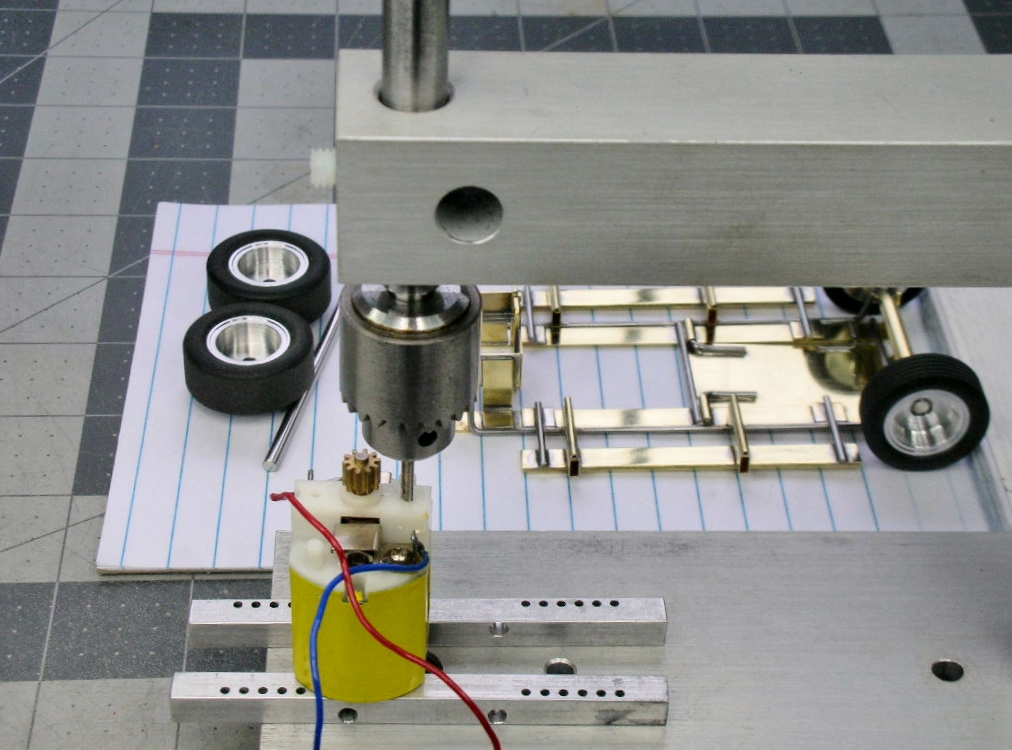

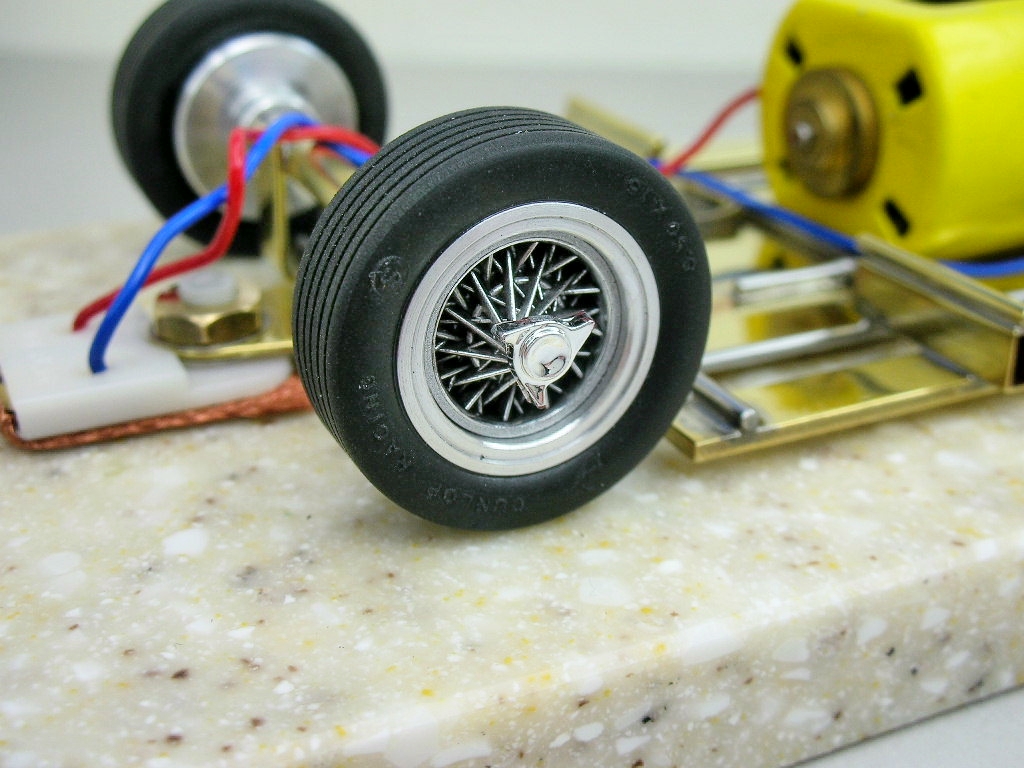

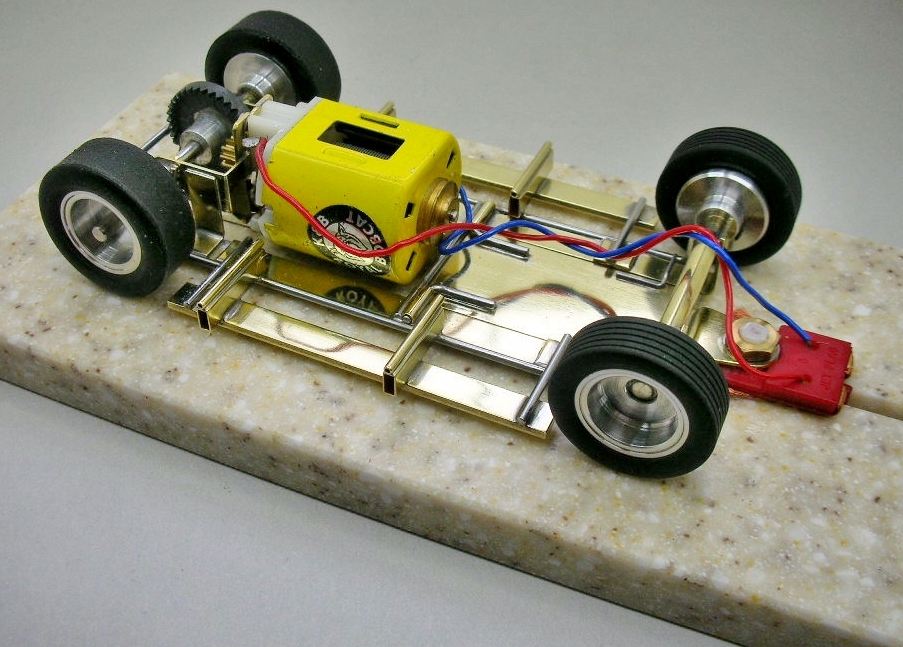

The crown gear is a 35T Weldun:

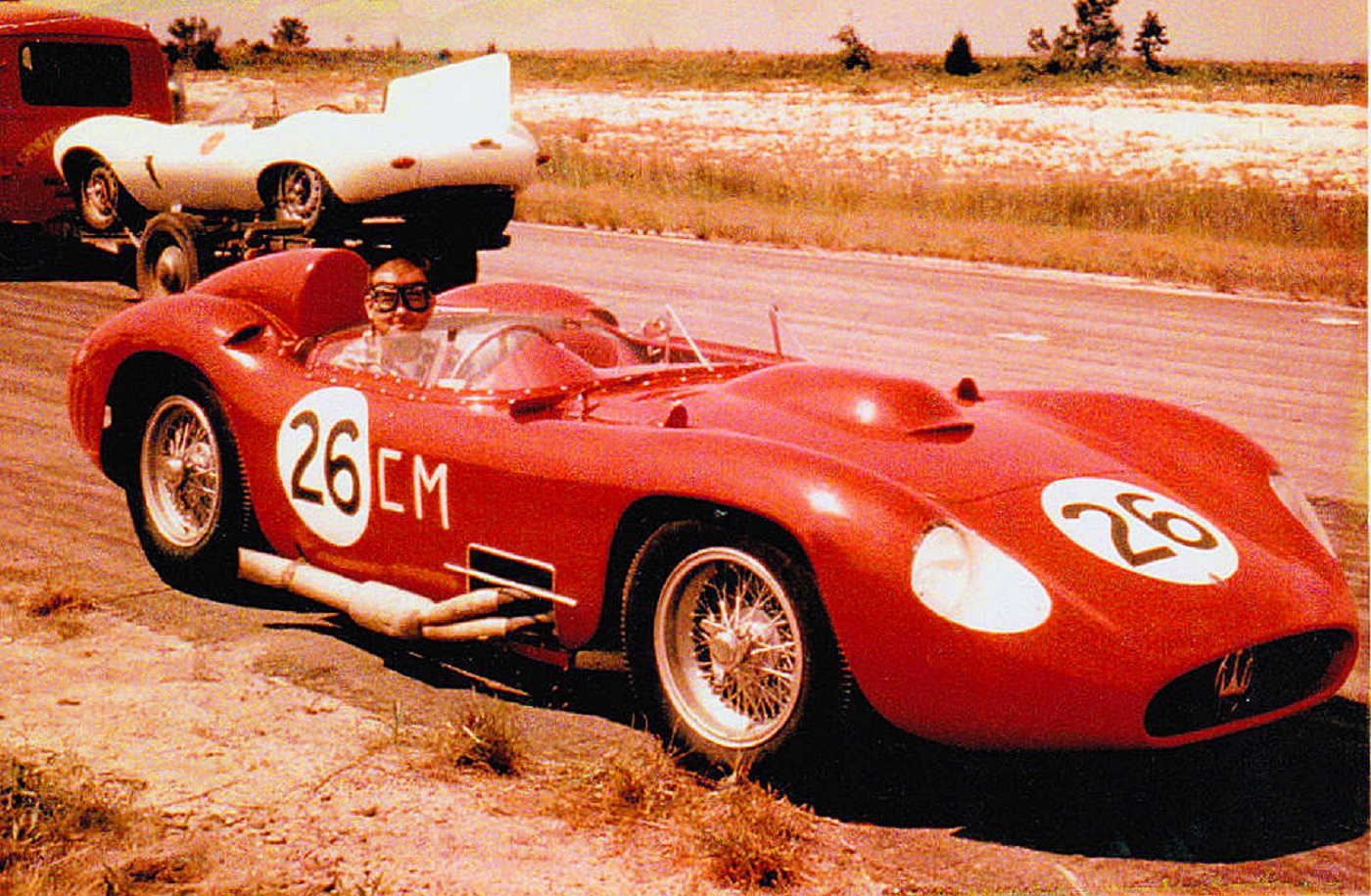

After running this car I was reminded why the 36D Mabuchi's pretty much replaced the Pittman's, Kemtron's, etc. with the average racers at the commercial raceways. It's pretty fast, has good brakes, runs cool and it's cheap.

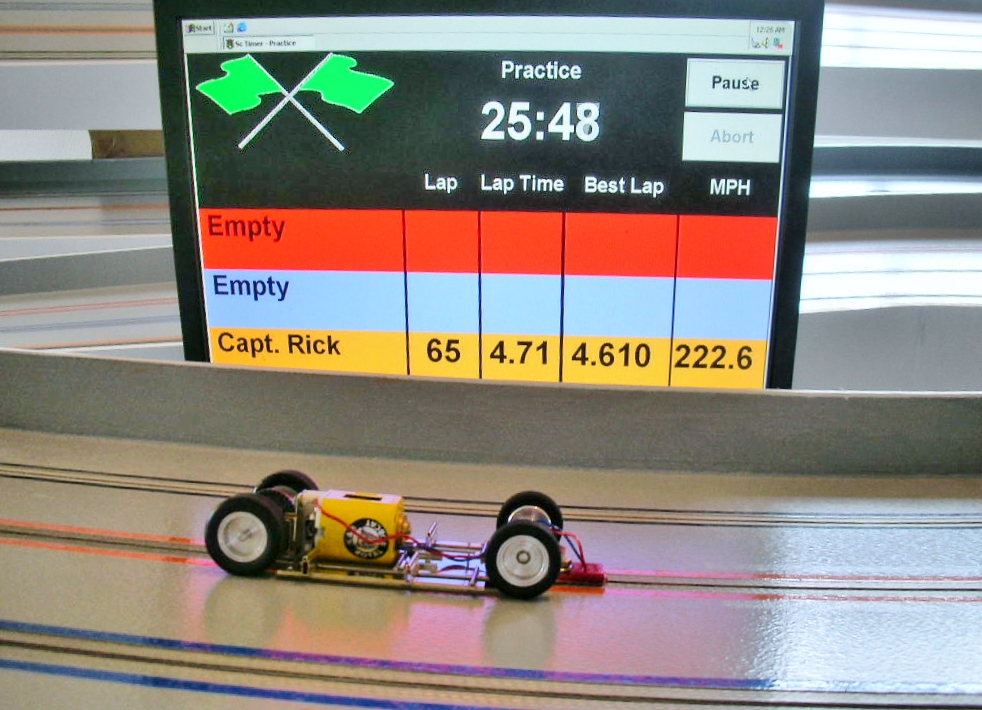

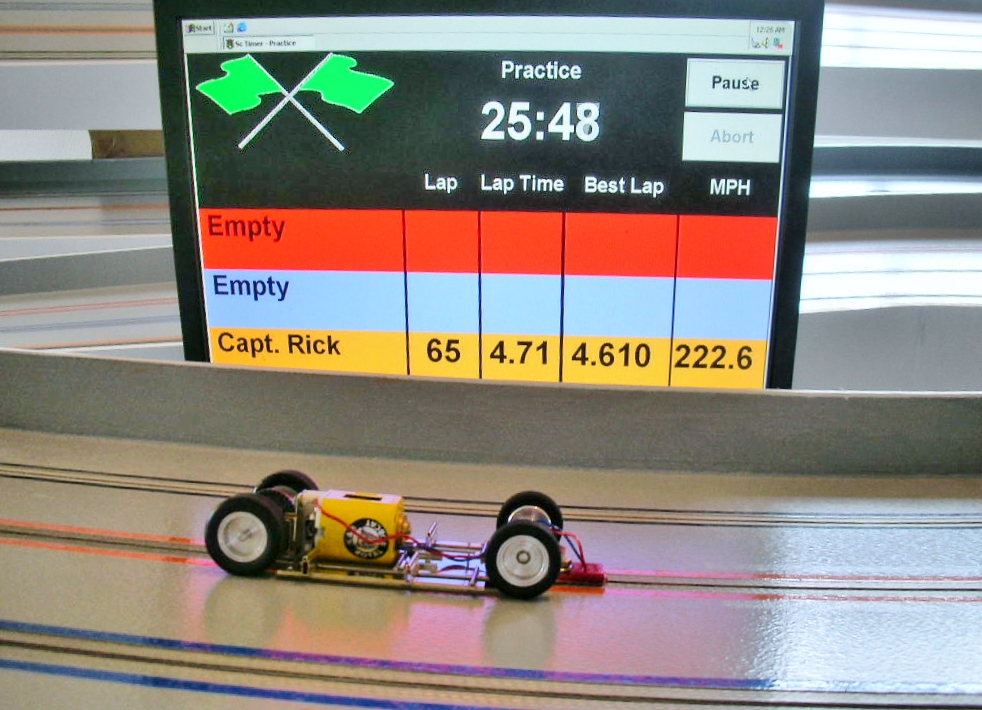

It also set the fastest lap time for my urethane tire equipped cars:

My other cars and their lap time are in the link below;

Track test lap times

There is a caveat to my lap times with the Veteran car. I didn't have a set routine for prepping the track surface for testing the previous cars. I used a method for the Veteran car that worked great for urethane tires and avoids spray gluing the entire track.

I clean the track with a Swiffer dry floor duster to pickup most of the dust and wiped my lane down with lighter fluid and a rag.

There is still enough dust on the track to really hurt performance. I can run just a single lap, the car gets squirrely and the tires are covered with dust again. I can clean the tires and repeat a thousand times, the tires still pickup dust and traction goes away after one lap.

BUT, if I put a little dot of glue on the tires, rub it in and run a lap the tires really pickup that dust. Cleaning the tires with lighter fluid and repeating the process a couple more times and the dust is gone.

Then I set the car at the start a turn with the dots of glued rubbed into the tires and drive a few laps. After repeating this for each turn the track is fine to run lap after lap without being squirrely. I really can't even see the glue on the track.

![]()