Page 3

What do we really know for sure because the last chapter was all speculation and fantasy on my part.

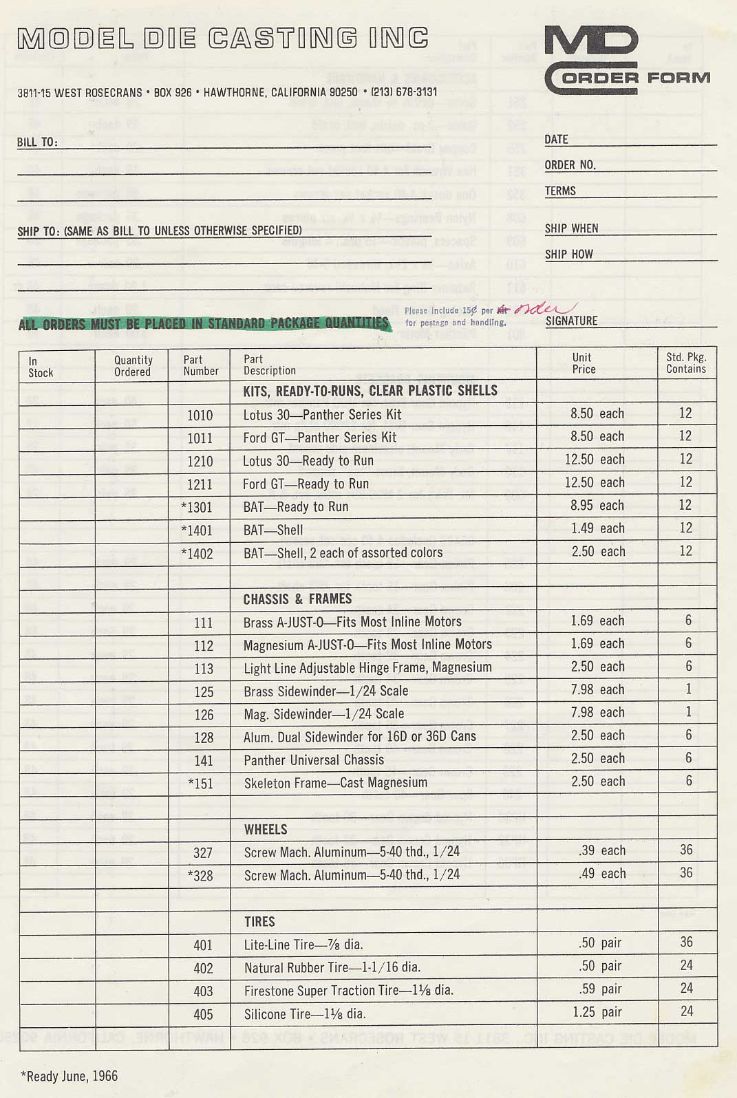

We have seen 3 cast metal chassis at the LASCM. I would think, and we have read, that there were a few prototype injection molded bodies around and of course the clear bodies that were sold in plenty back in the 60s?

That all changed after almost 60 years when a box of Bat bodies were found. They were auctioned 4 at a time for many weeks on eBay. Did you get any?

Hard to guess exactly how many were sold but I would guess some of you got some of them?

I won a few and parked those believing one day I would make a chassis that was very close to the original. At least in looks and fit. Sure would be nice to have a chassis that fits the body with no modifications as MDC intended.

Every now and then, I see Bat bodies for sale on eBay with different mismatched production chassis, and makeshift windshield etc.

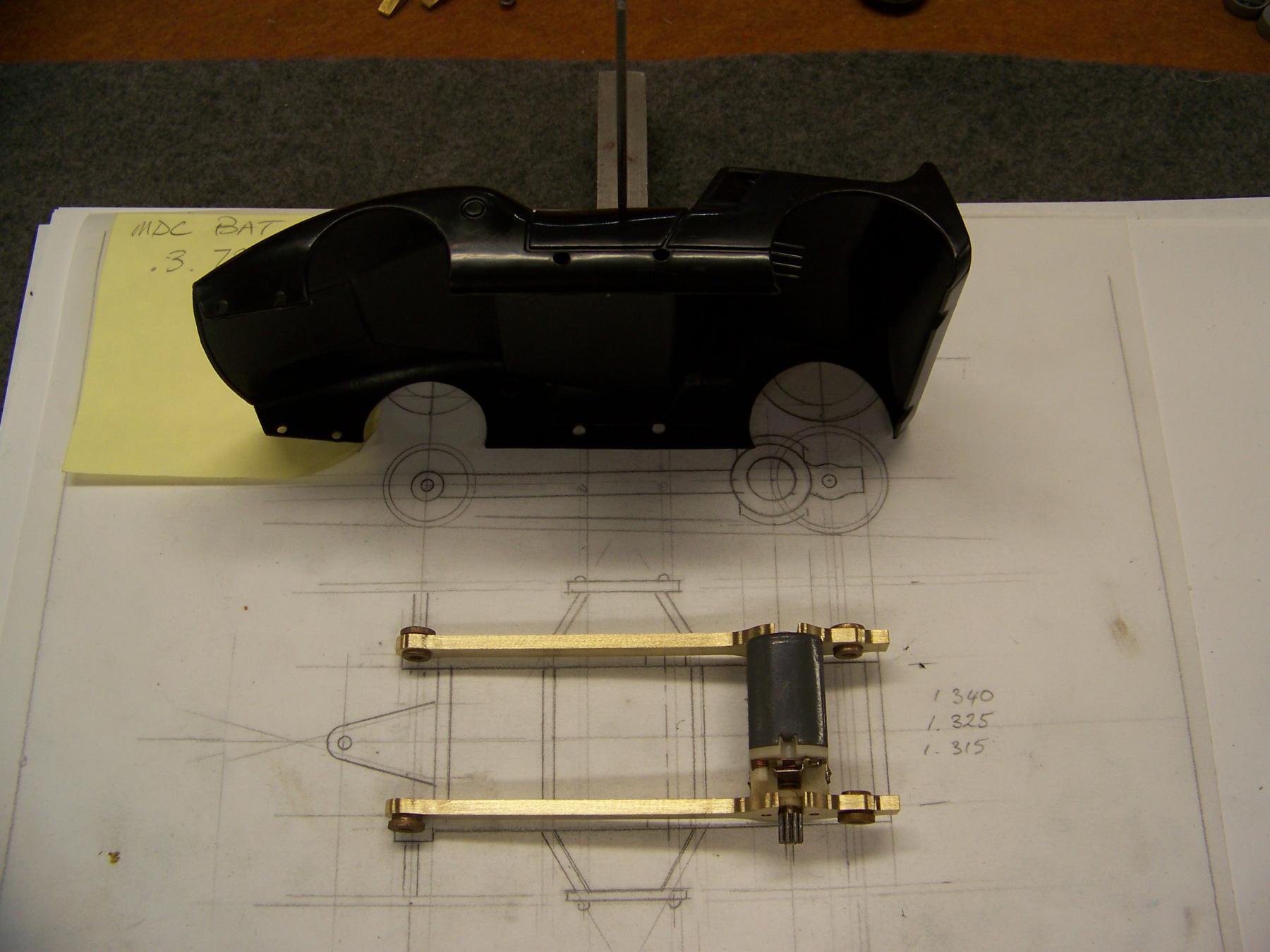

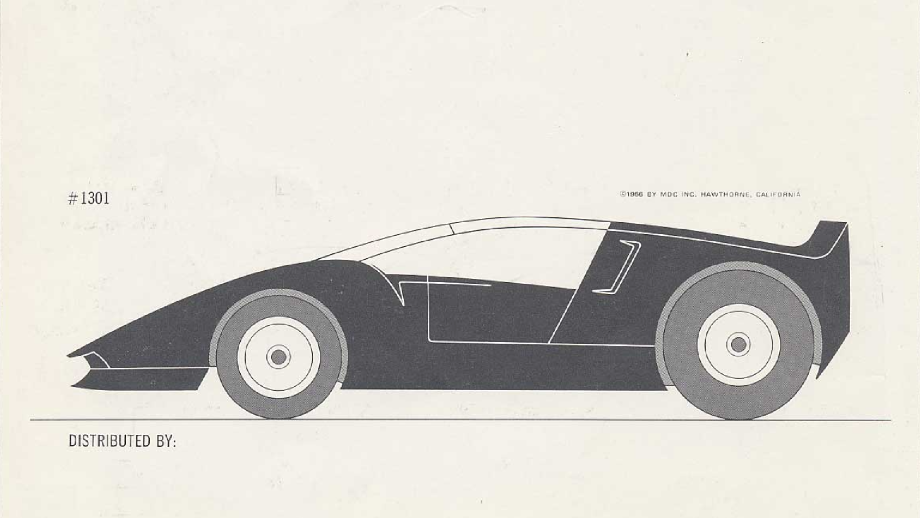

So the day arrived that I took a Bat body off my shelf and I made a scale drawing of what I was seeing from photos, and started to think how you would make this chassis today with the tools at my disposal. I studied all the pics I could find on the web and read all about how rare this body had been thought to be just a few years ago.

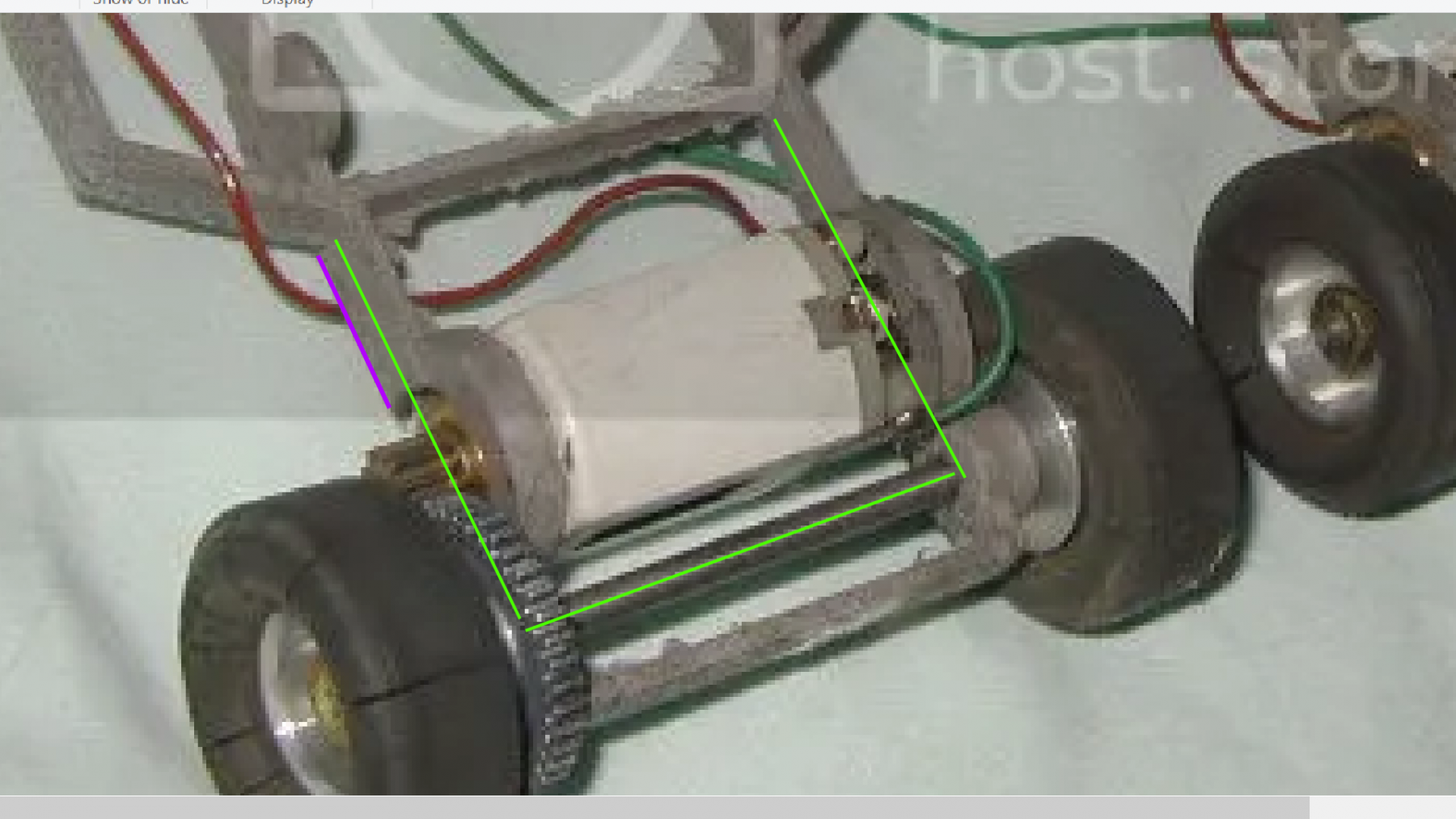

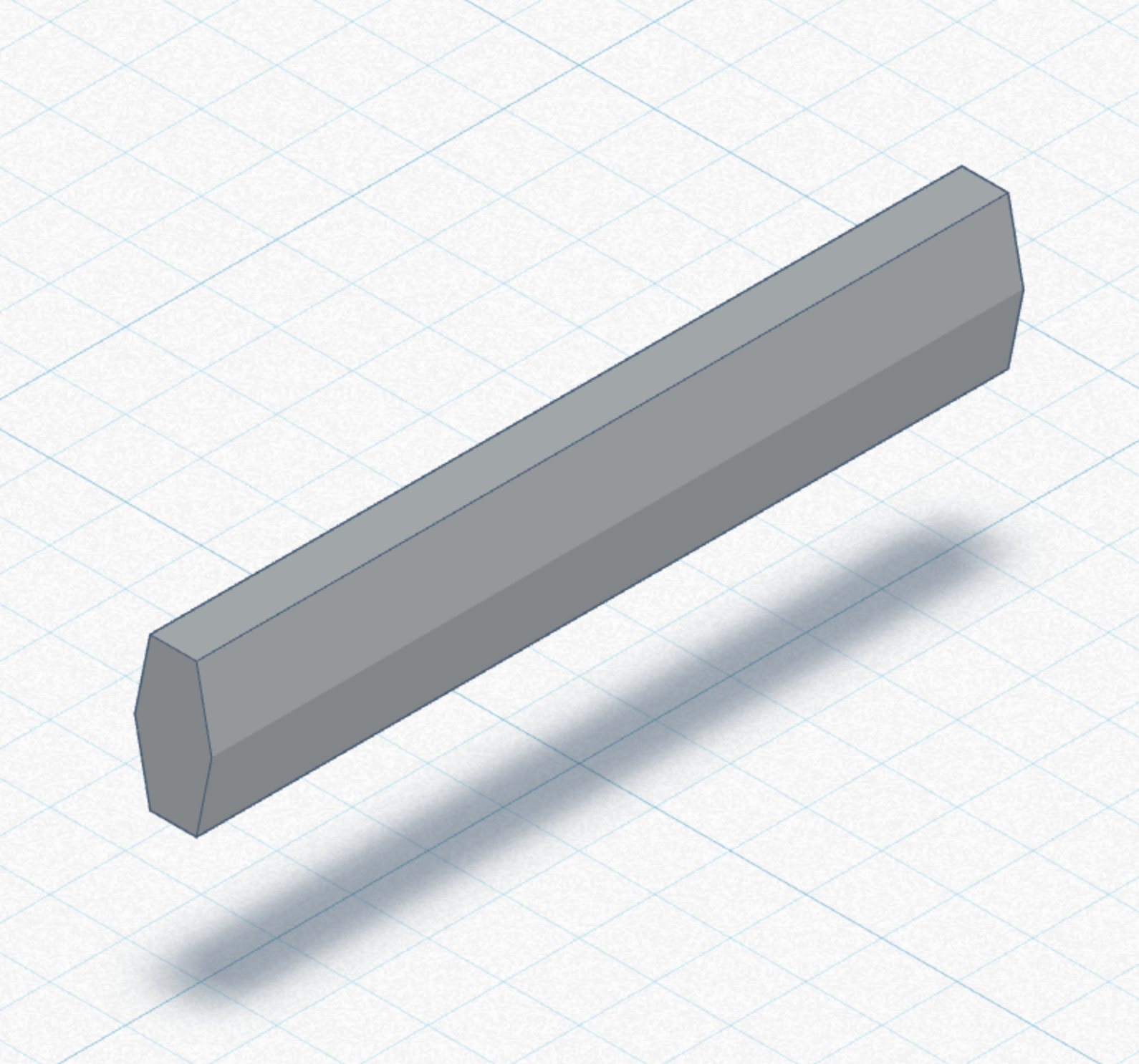

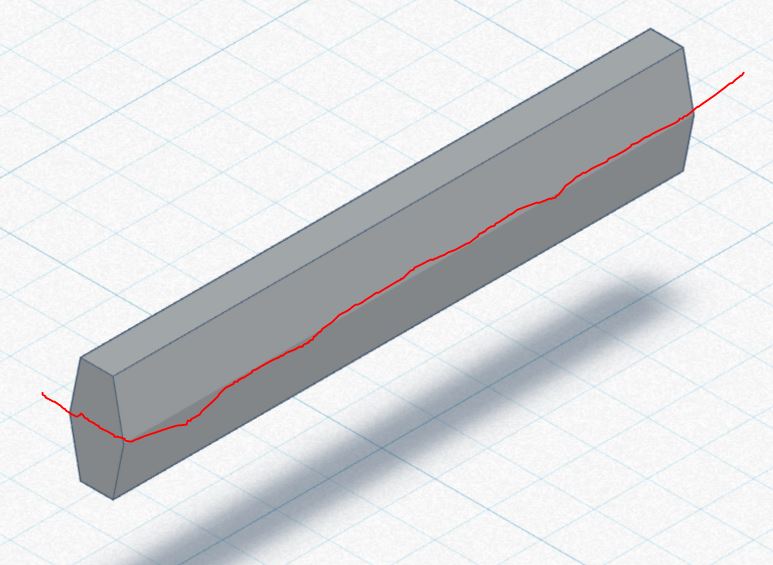

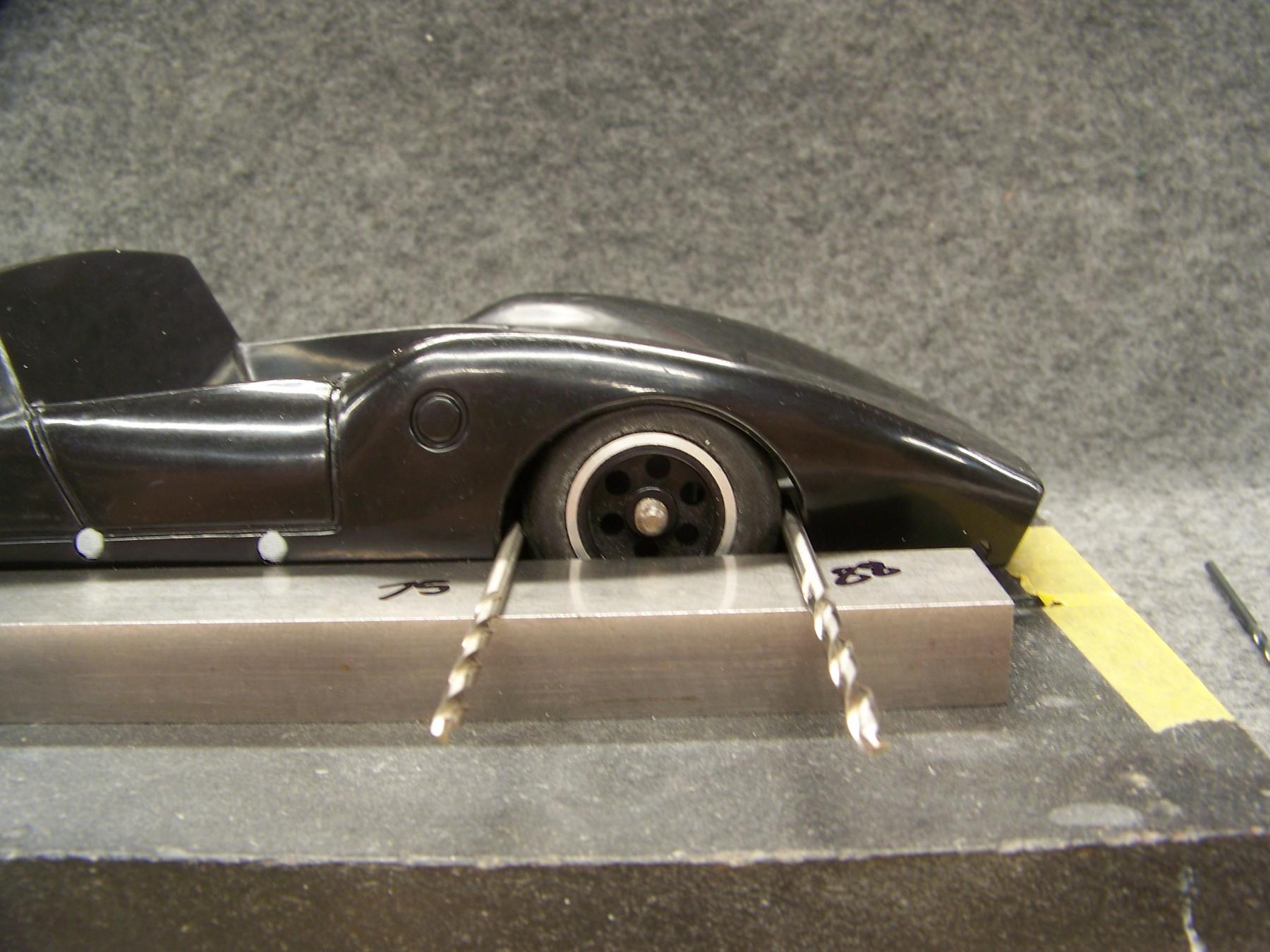

I made a brass sample of the main frame members that connected the rear axle motor and front axle, all on one straight line, kind of clever I thought and easy to do on my manual mill.

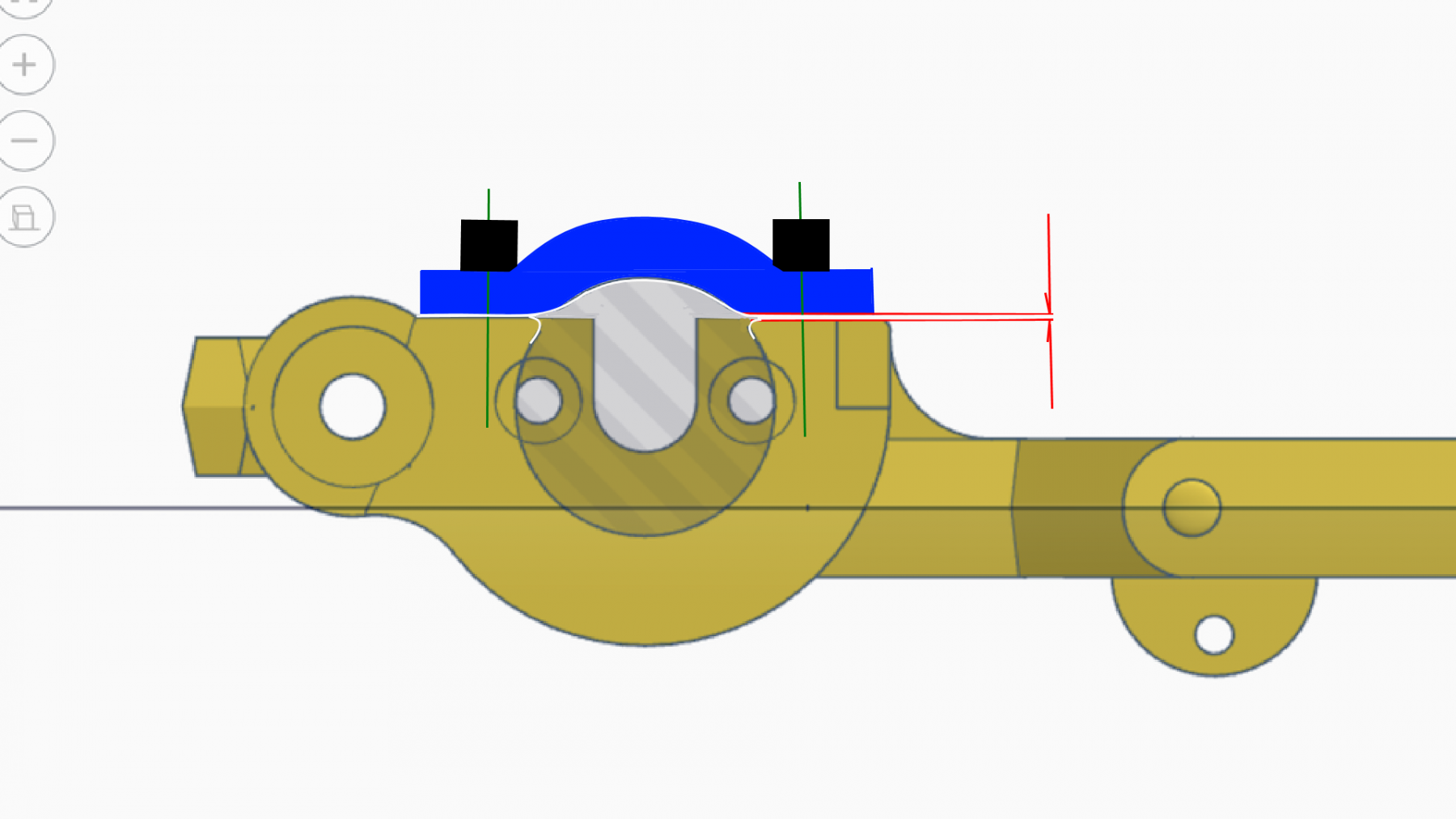

I mounted the motor, axles and mock-up wheels only to find out the chassis hit the molded interior tray and would not let the body sit anywhere close to fitting over the wheels. Glad I checked this at this stage, did MDC intend to cut out that interior part or ???

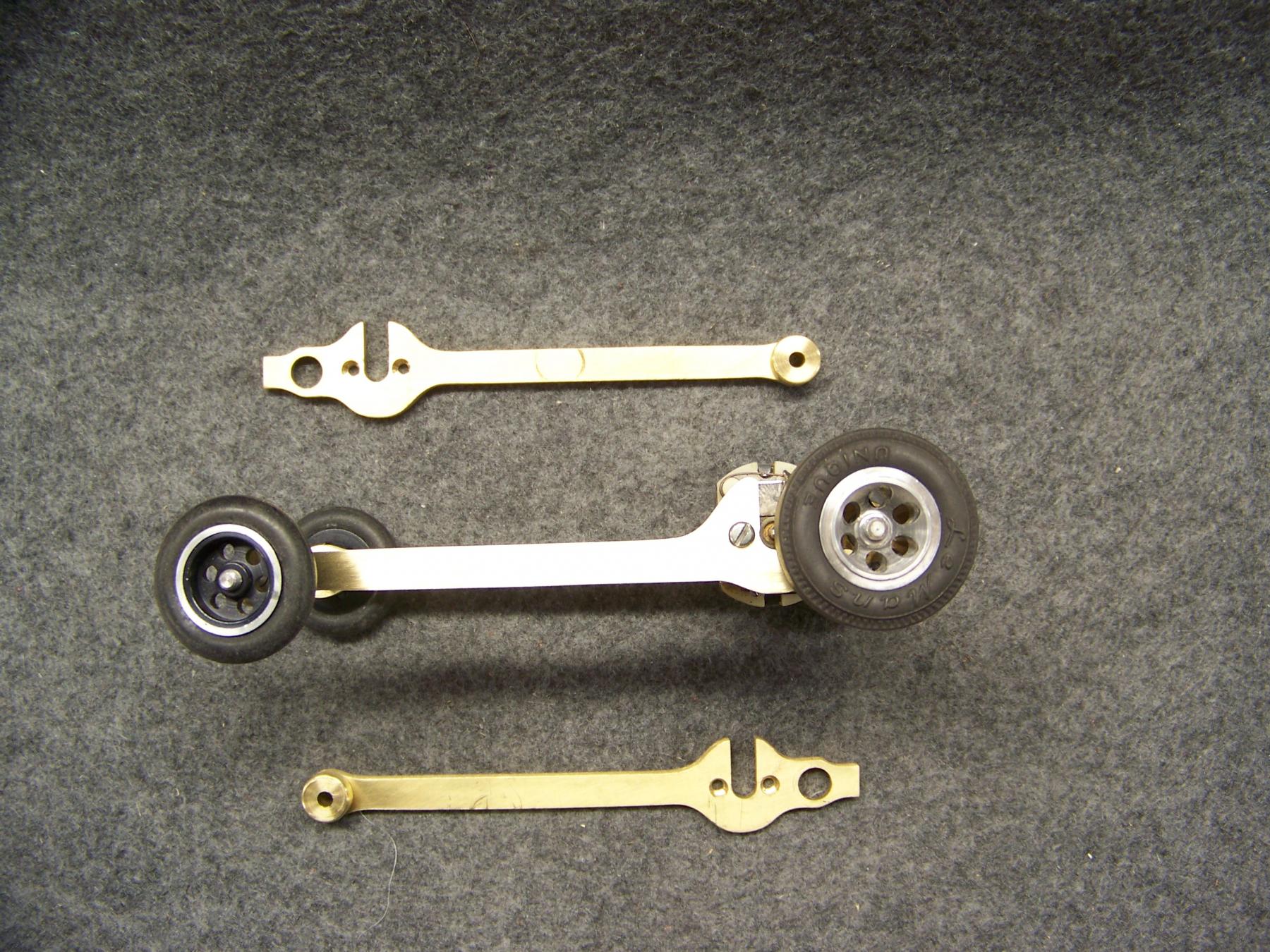

Anyway, time for version 2. Seen below and the 1st version to compare.

Second version seen here with the lowered frame rails so the body will sit down on the chassis as intended.

Is this oversight what killed the project almost 60 years ago????

Wow! what a thing to find out after the dies and tooling had been made.

So how to make this chassis so other folks could have this RTR car to drive and have in their collection too and to continue where MDC had left off.

CNC milled was considered. Too expensive with the number of operations and the fact that the chassis has a lot of tight corners and angles that would be hard to mill except with very small tools which would be slow to do.

Die casting, as the prototypes were done that way and would be the best option if it were not for the very expensive steel tooling that would be needed. The original tooling may be out there but still it does not fit the bodies that we have, so better think of a better solution.

Lost wax casting. Which I have a lot of experience with. Simple tooling but multiple steps, plus finishing, make this method too expensive also.

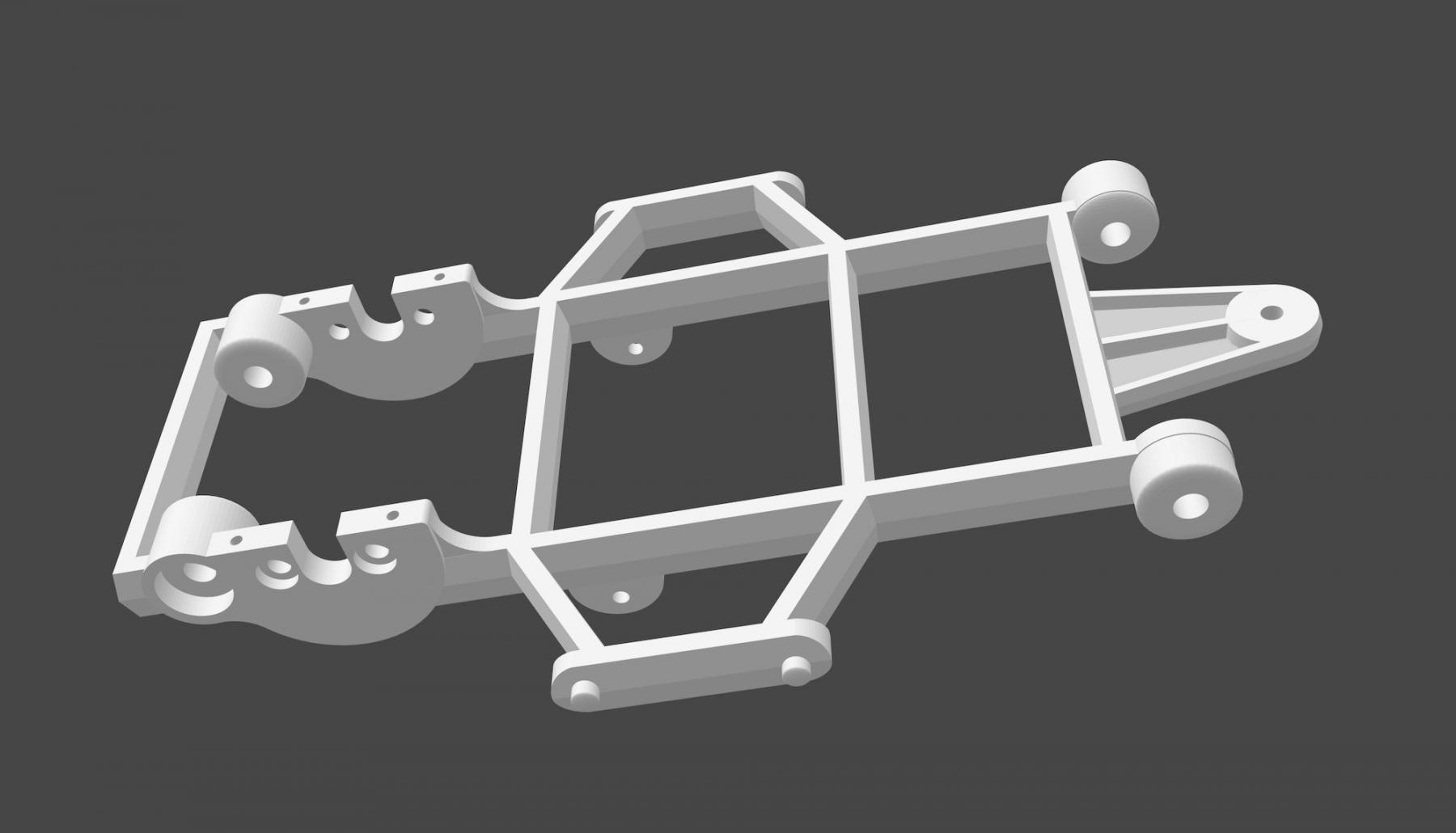

Then I remembered working with Larry on some 3D printed parts not so long ago. I called Larry and he was interested enough to look at my drawings and sketches and convert and turn into a file that we could do a 3D test print. Sounds easy but Larry spent a lot of time on details with enthusiasm and without complaint to make this chassis as close to what MDC would have made IF they would have made a chassis that actually fit the body correctly.

Of course MDC did not have computers or 3D printing to check fitment back then, but we do now, and we did. We made several test prints to make sure the body fit was correct and clearance over those big wheels was perfect. Making sure that gearing fitment was suitable also. As of this writing no track testing has been made, but we all know this type of design car was obsolete while it was being made at MDC in the 60's. So its place now is a collectable vintage car that for me will be fun to race with other hard bodied RTR cars of that period and style.

Probably not the only model that was just too late to the party. But it's a new day and a bit of revisionary slot car history.

The Bat is back and ready for a new build.