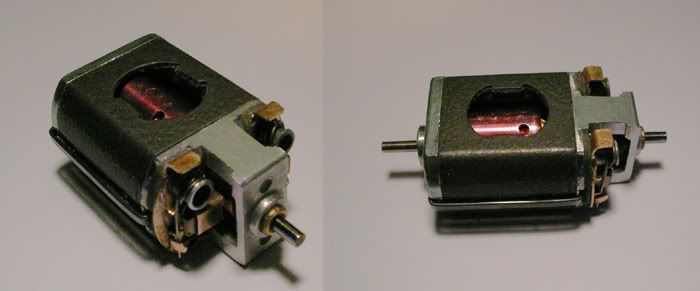

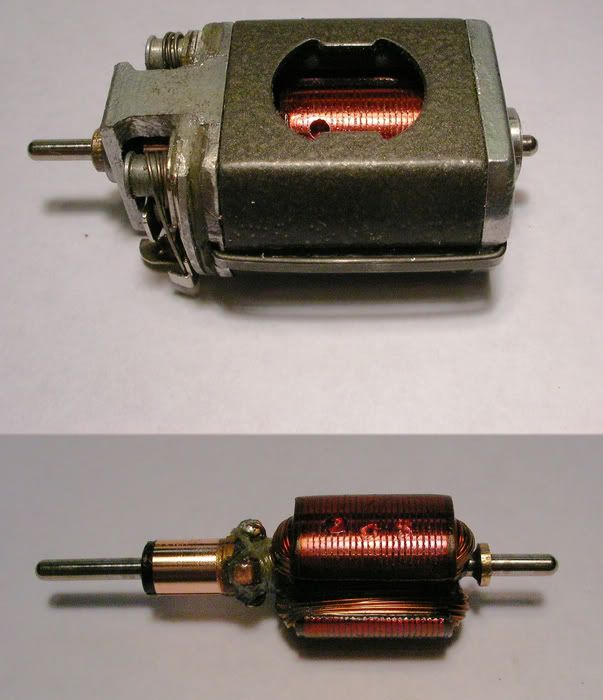

Anyway, I took the thing apart and it was clear right away that the endbell was in need to help...a lot of help. The brush carriers are molded plastic things that seem like they'd melt in a cup of coffee and there were floppy brass "hoods" that covered them and were pinned to the casting with a brass rivet and attached to the casting on the other end with a blob of silicone...and no where near perpendicular to the com. You can see one of them in the picture. So I removed those and layed-up four layers of fiberglass cloth and soaked it with high-temp epoxy, figuring it would be both a good insulator and fairly heat-resistant. When cured, I traced one of the plastic doo-hickeys on the fiberglass two times and cut them out. After all that, I bonded those to both sides of the endbell in preparation for building up something that is strong and more precise. I'm going to use some current Mura brush hoods, but have to devise a way to fasten them without creating shorts...I have some ideas. Anyway, here's what I have so far and I think I'm on the right track. Thanks again Bill!, this should be interesting

-john